Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

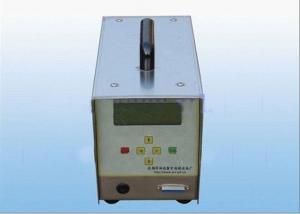

Electrofusion Welding Machine

1. type: electrofusion welding machine

2.welding range : 20~315mm

3. input power: 220V 50HZ

♦ Our eletrofusion welding machine adopt RMS control, main suitable for connection of PE pipes and fittings which are used for natural gas or water supply. It is the perfect equipment for manufacturers or construction units of pipes and fittings.

♦ High brightness LCD display. Chinese/English operation. Friendly interface for human and machine

♦ Wide power supply and voltage input, fully suitable for spot electric network wave

♦ High accurate power , time controlling. Ensure welding quality

♦Huge storage capacity for welding datum, easy way to enter welding parameters

♦ compact design, small volume and light weight

Dimension |

L×W×H(mm) |

330×200×270 |

Input data |

Input voltage |

48V±10%,220V±20% or 380V±20% |

Input power |

40~65Hz | |

Output data |

Output voltage |

0~50V |

Output power |

3.5KW | |

Main

Control

Specification

|

Environment temperature |

-15°C~45°C |

Storage temperature |

-30°C~70°C | |

Control ways |

Constant voltage/currency/power | |

Data record times |

500 | |

Power constant precision |

≤±0.5% | |

Overload capacity |

1.5Ie,1 minute | |

Time control precision |

≤±0.01% | |

Temperature measurement precision |

±0.5°C | |

Duty rates |

60% | |

Data output |

RS232 | |

protection |

See the fault sheet | |

Soft operation |

Windows 2000/XP |

- Q:What is the use of electroslag pressure welding machines, alternating current welding machines and flash butt welding machines?

- Agree with the upstairs, as well as mechanical connections, mechanical connections, more than 18 of the province's steel, reasonable price, can be used for Liang Jizhu, foundation and other components

- Q:Saw welding is the use of welding machine, I do not know how good tempering, tempering to what extent, I always break the interface

- Is still another comes back lighter annealing function? It's not a word to make it clear

- Q:With steel wire welding, after welding, gently Wei, solder joint fractureReply immediately when you knowSpecific how to heat preservation, can say detailed point?

- Preheat before welding and cool down after welding

- Q:Technical operation of welding machine

- Two or three discharge pulse welding, for medium and high carbon steel refueling, preheating, integer and annealing function. It is not only suitable for butt welding of compact wire, but also for butt welding of expanded plate (low carbon copper, pure copper, brass, low carbon steel, medium carbon steel, stainless steel, aluminum and metal wire). A microcomputer processor is used to control the welding process. The welding parameters such as clamping, welding, upsetting and stopping can be adjusted and controlled. The equipment is easy to operate and easy to master. The utility model relates to a lever type pressurizing structure, which has more pressing pressure in the unit area, and ensures the stability of the welding of the product.

- Q:How to use the butt welding machine for band saw blade?

- Adjust the welding contact space to 18-20 mm wide. Then put the saw on it and press it tightly. Two 、 adjust the current to the minimum. Three, quick click switch. Four. Observe the weld until it is slightly aglow. So far, the annealing is complete. There is a problem to go "woodworking belt saw blade" stick to me

- Q:How to use PE electric melting machine PE electric welding machine

- Electric welding machine operation steps: 1. Prepare electric welding machine, welding PE pipe, pipe fittings. 2 remove the oxide layer at the insertion point of the PE pipe and insert into the fused pipe. The insert pipe to easily insert is appropriate, do not force the pipe in pipe, fitting into tight during the welding process due to the shift of electric heating expansion of PE material after heating, thereby changing the temperature change of heating, easy to cause local heating caused by the over high temperature of the welding smoke and other phenomena. Special circumstances such as pipe insert is not in a straight line, i.e. pipes and fittings are not coaxial, this situation need to use special line for fixed pipe and pipe fittings, pipe insert to reduce stress. 3, after being ready, the output electrode of the welder is inserted into the electrode column of the pipe. 4. Start the electric welding machine, scan the bar code, or enter the welding voltage and time parameter, then start welding. 5, after the end of the welding countdown, without affecting the cooling of the pipe welding, you can remove the output cable, and begin to prepare the next welding.

- Q:When welding, the machine needs water to cool it

- I have seen many pairs of welding machines in the construction site, and no water cooling is needed.

- Q:When the wiring of the motor is connected, how many transformers can be used for the welding machine, and the AC output of the transformer is also changed into direct current?

- 300W power is enough, I use the output of 35V is connected with a battery element on the line, and the voltage is adjustable easily.

- Q:What is the difference between an electric welding machine and a butt welding machine?

- Welding machines work by electricity. The name literally means of welding machine is too deep for you to check the information!

- Q:What's the biggest difference between domestic and imported steel cord welder? Besides price?

- That depends on what route your product is going through. Just like buying a car, Mercedes, S600 and Santana can be used to see your needs.The first few years I used the domestic welding machine, not considering the price asked, is worried about the problem of customer service, then domestic welder repair rate so I really can not stand, they have changed, found before the worry is redundant, the first machine isn't bad, even if some supplies needed through the replacement purchase agent is also very convenient, are the basic spot.Not to say that domestic things are not good, but it is so breath. Very helpless.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | |

| Main Markets | 40.00% Domestic Market 15.00% Mid East 10.00% South Asia 10.00% Southeast Asia 10.00% South America 5.00% Eastern Asia 5.00% Africa 5.00% North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Russian, Korean |

| b)Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Electrofusion Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords