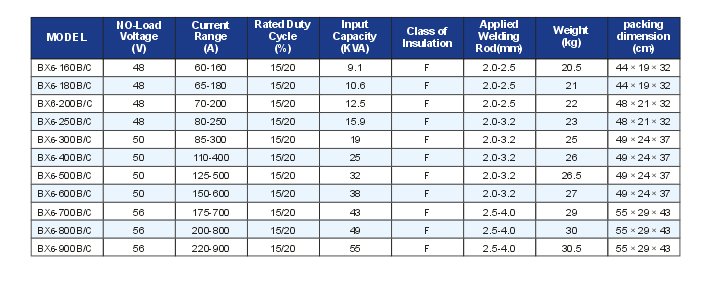

BX6-B Series AC ARC Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Top type transformer, step current adjustment fan cooling, high efficiency and safety

Compact, light, portable suitable for

Instruction of BX6-B Series AC Arc Welder

Top type transformer, step current adjustment fan cooling, high efficiency and safety

Compact, light, portable suitable for home and small factory

We have two kinds of welder, one is aluminium, one is copper

- Q:I bought an argon arc welding machine on the current, frequency, gas and so on how to adjust? Thanks

- The current is according to what you want to use the welding materials, general material is thin, you need a smaller current; the frequency is not the duty ratio is? If it is to have a product object welding flaps only need the extension; gas is you press the torch switch, the gun will the "gas" as one sound, you open more, when you continue to end things after welding gun argon on longer, I personally think it is not recommended to switch too, is a waste, one is not too easy to play. Flint fire easily after the injury is not blowing material. You know there is no arc current machine, gas testing switch

- Q:The difference between AC argon arc welding machine and DC welder

- The difference between AC argon arc welding machine and DC welder:1, DC TIG welding, the DC positive connection with argon gas protection, with between the electrode and the welding arc in certain requirements (welding current), heating and melting of the parent material, adding wire wire to melt into the molten pool, the formation of weld cooling.In addition, 2 pulse argon arc welding, DC TIG welding specification, can independently adjust the peak current, base current, pulse width, pulse period or frequency parameters, compared with DC argon arc welding has the following advantages:(1) increasing the depth to width ratio of the weld, the width of the weld can be increased to 2:1 when the stainless steel is welded(2) to prevent burning, in the thin plate welding or thick plate backing welding, with the peak current through the time, the weldment is welded through, before the pool obvious subsidence, go to the base value current, make the metal solidification. Also, there is a small current to maintain the arc until the next peak current is circulating.(3) reducing the heat affected zone and welding the heat sensitive material, reducing the pulse current through the time and the base current value can reduce the range of the heat affected zone to the minimum, so that the welding deformation is small.(4) increase the stirring of the molten pool, at the same average current value, current value than a constant current high current pulse peak, so the arc force, strong mixing effect, which helps to reduce joint at the bottom of the hole and may not fusion phenomenon. In small current welding, the higher pulse current peak current enhances the arc stiffness and eliminates the arc drift phenomenon.

- Q:Which is good for mould argon arc welding machine Ws and TIG?

- WS easy to useTIG refers to low-power tungsten arc welding such as TIG-160, TIG180, TIG-200 and so on. Civil small batch work can be used.WS refers to the power of non consumable (Wu Ji) inert gas shielded arc welding, argon can be used, you can also use other inert gas, power, multi-function, used for pipeline backing welding, pressure vessel welding backing, non-ferrous metal welding, or other important structures..

- Q:How do we need welding with argon arc welding machine, and what tools do we need? Please explain in detail, satisfaction added 10 points

- DC argon arc welding machine is not welding aluminum, with DC argon arc welder, welding of aluminum can, to communicate with, if you need to pass beautiful with DC argon arc welder with pulse welding sheet, do not fill the thick aluminum wire, you need to fill in the aluminum wire.

- Q:There are several kinds of arc welding machine, argon arc welding machine and several kinds. What are their occupational hazards?

- Manual arc weldingArgon tungsten arc weldingCarbon dioxide gas shielded arc weldingsubmerged arc weldingmetal inert-gas welding

- Q:What is the function of an argon arc welding machine with current attenuation function?

- Yours is a dual purpose welder. Is used to welding electrode, sometimes the current is small, welding rod is not good, arc will be sticky when. Adjust the thrust, the current is good, the arc started. To put it bluntly is to help lead the arc. Also in use, that is, vertical welding or overhead welding is to help the particles transition. Under normal circumstances, it doesn't help much. Generally do not open. You'd better not open the assembly to increase splash

- Q:How to weld aluminum material with argon arc welding machine

- No thorium tungsten or cerium tungsten welding steel pole with pure tungsten, alternating current, welding wire and base metal components. Similar aluminum heat quickly, the temperature of the base metal with the welding process in the continuous increase, to grasp the welding speed and wire feeding speed (generally with the welding process, to speed up the best lining pad. Flow) the welding pool of aluminum is not good, not easy to end with the best fusion butt welding arc plate and arc plate. Aluminum easy arcing, should pay attention to stopping.

- Q:Argon arc welding machine has high frequency spark, no arc, what are the reasons? Repair steps: argon arc welding machine has high frequency sparks, no arc, check whether the gun has sufficient amount of argon to come out, and then see if the cable is broken!I have encountered such a situation when the broken welding torch cable, welding machine apart was measured with a multimeter in many places did not find the problem, then the part of the high pressure spark open press with a multimeter to check the output terminal of the switch + fast welding (workpiece) and - (argon arc welding) end are the normal voltage, (at that time not see) arc welding torch cable can be! The torch cable to replace fixed ~!

- Brother, you are the same as me! Every step has been checked: no problem! Later also changed the welding tape. The trouble has been eliminated!

- Q:ZX7 inverter type DC arc welding machine, when the welding current is 150A, how much power can it have?

- Probably can only be calculated when welding in general, because of the arc, the arc of that moment consumption is relatively large, the arc voltage of 70V welding voltage is about 30V, according to Ohm's law 30 multiplied by 150 ampere voltage =4500W is 4.5 kW and its loss is less than 100W and the total power should not arc to 5KW, the welder should also consider the sustained load, generally less than 60% of the whole ZX7 is saving than at least half exchange

- Q:It can not be adjusted by ordinary welding

- Or adjustment switch is a problem, and then either 380 of the welding machine connected to 220 of the power supply, and the last case, high voltage package problems.

We enjoy good reputation at home and abroad. Our company specializes in manufacturing motors, pumps, air compressors, welders and cutters, etc.

We have enjoyed high favor among the customers. In addition, we can produce motors according to the request of the customers. At the same time, we supply complete inspection of electric property and mechanical property. Your coming and choosing our products will be sincerely welcomed. We will sincerely supply best services for you.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China (Mainland) |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | North America3% .South America3% .Eastern Europe5% .Southeast Asia12% .Africa20% .Oceania1% Mid East30% .Eastern Asia5% .Western Europe5% .Central America3% .Northern Europe3% Southern Europe2% .South Asia8% |

| Company Certifications | Certificate of Conformity;Certificate of Conformity |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BX6-B Series AC ARC Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords