Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydrophobic Pleated PTFE membrane filter cartridges for sterile air or solvents

PTFE Filter Cartridge

PTFE Filter isa sterilizing grade air & gas filter that utilize naturally hydrophobic

material provides effective retention of microbes and particles in air/gas.

Features

l Inherently hydrophobicity.

l High flow rates at low differential pressures.

l High steam cycle lifetimes and thermal strength.

l Reliable separation of microorganisms and bacteriophage.

Materials

l Media Layer: Hydrophobic PTFE

l Support Layer: Polypropylene

l End Caps/Core/Cage: Polypropylene

l O-Rings/Gaskets: Silicon, EPDM, Viton, Teflon

l Internal Adaptor Ring: PS / Stainless Steel 304

Operating Conditions

Max. running temperature | ≤80 ℃ |

Max. Allowable Differential Pressure | ≤5Bar(20℃) |

≤2Bar(80℃) | |

Inline Steaming Sterilize | 121 ℃, 30min@max differential Pressure of 0.05MPa up to 25 times |

Food and Biological Safety

Extractables | <30mg per 10 inch |

Endotoxins | <0.25EU/mL |

Ordering Information

PTFE | Micro Rating | Connection | Length | Gasket |

01=0.1μm | 0=222+Flat | 10=10 inch | S=Silicon | |

02=0.22μm | 5=222+Spear | 20=20 inch | E=EPDM | |

04=0.45μm | 7=226+Spear | 30=30 inch | V=Viton | |

10=1μm | F=DOE | 40=40 inch | F=PFA |

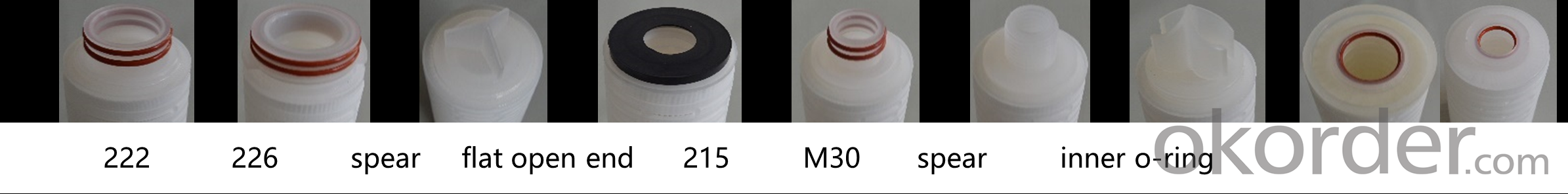

Connection details

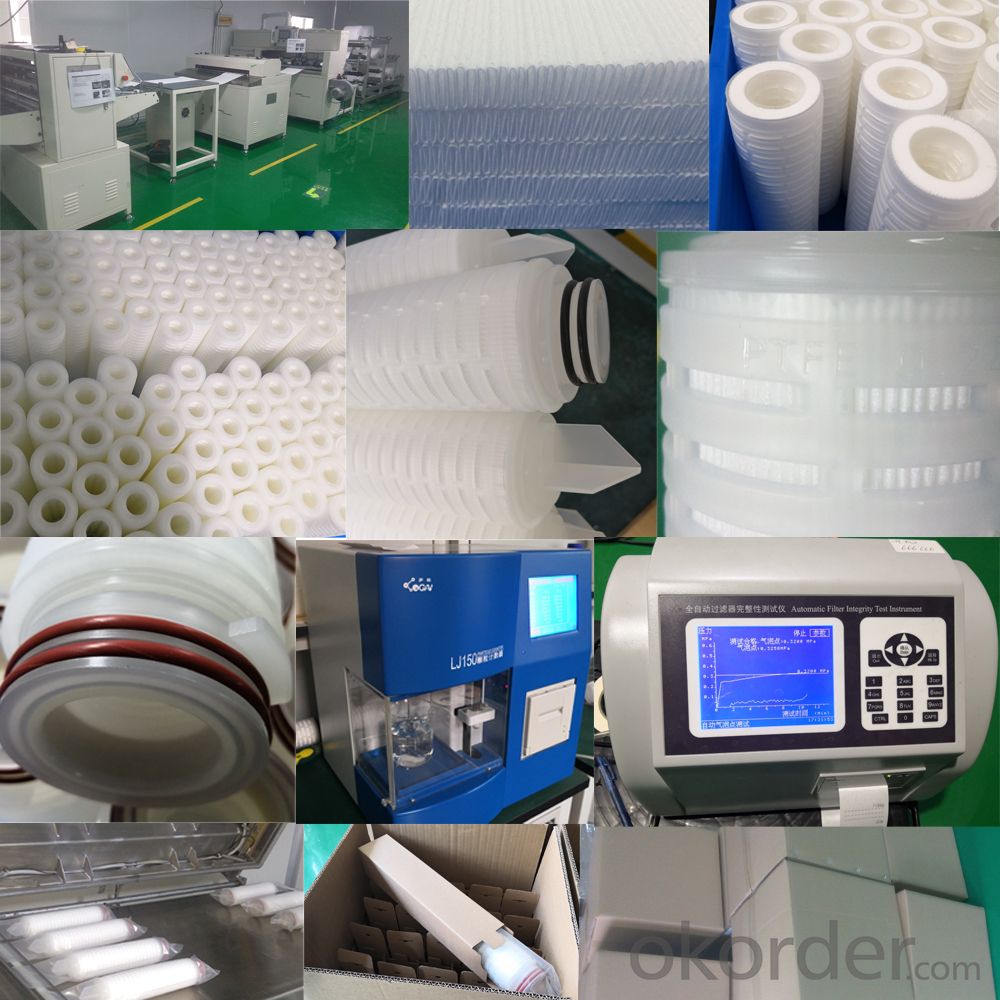

Process

- Q:Could you tell me how to make the filter, and mine is also very delicious and urgent. Thank you

- he smell is mainly activated carbon filtration, but before it to filter out dust or activated carbon will soon be buried on the dust.. by two or three layers, a layer of coarse filter with acrylic foam

- Q:How is the flow rate of an industrial automatic water filter calculated?

- The material and structure of the screen can greatly improve the flow area of the flow, effectively reduce the water resistance of the filter screen, and ensure the reliable operation. No jam, jam or plug occurs.

- Q:How can the filter core of the filter installed in the industrial pipe installation be fixed? Seek professional answers

- can add a material alone in the wood, in the installation a filter element fixed inside. If the material does not conduct market inquiry after the corresponding input price of the material in the construction process of visa.

- Q:Which manufacturers produce ceramic filters, the more comprehensive the better, the people throughout the country hooray!

- Huizhou Copper Crown machinery, Yantai nuclear industry, Yixing non - metal chemical industry, Anshan also has one.

- Q:What about the quality of industrial filters, filter cores and filter bags produced by fly wave filtration?

- At the same time, the company continues to standardize the production process and quality specifications, is ISO9001, ISO14001, ISO18001 certification enterprises.

- Q:Classification of filters

- . After the filtrate is sucked out, the filter is drawn out by the catheter, and the filter residue accumulated on the surface of the filter leaf is removed after stopping. The continuous operation of the vacuum filter is suitable for thick suspension filter containing solid particles more. Rotary drum vacuum filter, internal filter drum, vacuum filter, disc vacuum filter and tipping bucket vacuum filter are similar in principle.

- Q:Application range of quartz sand filter

- can be widely used in electronics, power, petroleum, chemical, metallurgy, electroplating, paper making, textile, pharmaceutical, dialysis, food, beverages, drinking water, factories, enterprises, water, swimming pool, etc.. Can meet the needs of liquid filtration in various industries.

- Q:Procurement of an industrial pure water equipment, need to pay attention to what problems, industrial pure water equipment, water quality can achieve what standard?

- It usually includes pretreatment system, reverse osmosis device, aftertreatment system, cleaning system and electrical control system, etc.

- Q:The south is well-known, the strength of the production of filter cloth or industrial filter cloth manufacturers?

- Shanghai Chang Bo filter industry Co., Ltd.

- Q:How about water treatment equipment, water treatment equipment?

- The quality and quality of the water treatment equipment is still good. Water treatment equipment can be divided into the main categories of sewage treatment equipment, water purification equipment, filtration equipment, ultra pure water equipment these categories. These water treatment equipment have different uses. Here are some of these water treatment equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products