Electrofusion Machine 20-315mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

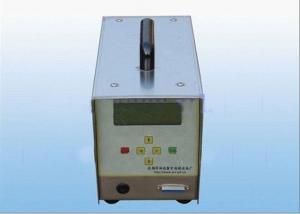

20~315mm Electrofusion Machine

1. type: 20~315mm electrofusion machine

2.welding range : 20~315mm

3. input power: 220V 50HZ

♦ Our eletrofusion welding machine adopt RMS control, main suitable for connection of PE pipes and fittings which are used for natural gas or water supply. It is the perfect equipment for manufacturers or construction units of pipes and fittings.

♦ High brightness LCD display. Chinese/English operation. Friendly interface for human and machine

♦ Wide power supply and voltage input, fully suitable for spot electric network wave

♦ High accurate power , time controlling. Ensure welding quality

♦Huge storage capacity for welding datum, easy way to enter welding parameters

♦ compact design, small volume and light weight

Dimension |

L×W×H(mm) |

330×200×270 |

Input data |

Input voltage |

48V±10%,220V±20% or 380V±20% |

Input power |

40~65Hz | |

Output data |

Output voltage |

0~50V |

Output power |

3.5KW | |

Main

Control

Specification

|

Environment temperature |

-15°C~45°C |

Storage temperature |

-30°C~70°C | |

Control ways |

Constant voltage/currency/power | |

Data record times |

500 | |

Power constant precision |

≤±0.5% | |

Overload capacity |

1.5Ie,1 minute | |

Time control precision |

≤±0.01% | |

Temperature measurement precision |

±0.5°C | |

Duty rates |

60% | |

Data output |

RS232 | |

protection |

See the fault sheet | |

Soft operation |

Windows 2000/XP |

- Q:How to choose welding leakage current

- First calculate what your total power is, then select the leakage switch according to the power.The power / voltage is equal to the current. For example, the total power 4KW, then 4000/220=18A.The rated current of the leakage switch is greater than the load current.In general, the total leakage switch is selected by 1.5 times the load current, 18A*1.5=27A.There is no leakage switch for 27A, soThe leakage switch should select 32A.The leakage current is selected by 30MA.

- Q:380V 150KVA flash butt welder, what kind of cable do you need?

- The wire diameter is usually calculated according to the following formula:Copper wire: S= IL / 54.4UAluminum wire: S= IL / 34UIn style:I - the maximum current (A) passed through a wireL - the length of the wire (M)U - permissible power drop (V)S - cross sectional area of the conductor (MM2)So, you know what material and how long wires can be used to determine how much cable you want.

- Q:Leakage switch operating current 30mA can not meet the use of steel butt welder, how should I do?

- Should be able to change the size or change the same size leakage switch (action current optional)

- Q:How to use the butt welding machine for band saw blade?

- I have detailed instructions, you can add me, I will send you

- Q:How long does it take for electroslag welding machine to butt a steel joint? Which kind of butt welding method is adopted for steel butt joint on construction site? Which welding machine is the best?

- Electroslag pressure welding is only used for vertical or small angle steel butt joint, the diameter of reinforcement is 12~20mm. The vertical reinforcement of the column longitudinal reinforcement and shear walls is used on the site. Electroslag pressure welding is a portable, moving and flexible device. The welding speed is fast, and each joint is completed in about ten minutes.

- Q:How to use PE electric melting machine PE electric welding machine

- Connect the electrofusion pipe to the electric welding machine and plug in both sides of the PE pipe which needs welding. Select the welding time, temperature and other parameters on the electric melting machine, and then operate according to the instructions of the electric melting machine. Different electro melting machines operate slightly differently, not too complicated.

- Q:What is commonly used in welding excavator bucket machine good

- Most of the manufacture now uses carbon dioxide gas protection! Repair, then the general electrode arc welding enough!

- Q:When the wiring of the motor is connected, how many transformers can be used for the welding machine, and the AC output of the transformer is also changed into direct current?

- How do you solder it?! Not yet! Please consult me! Like an electric welding? I

- Q:Do welding electrodes need to be used for the welding machine? Will there be smoke and dust in the welding process?

- Without electrode. Basically no smoke and dustTwo metal charged collision, instantaneous short-circuit discharge

- Q:Construction steel butt welding or welding good?

- If you have to choose the resistance butt welding electrode arc welding steel bar, then resistance butt welding.However, the power consumption of resistance butt welding is great, and the rate of welding finished products is lower than that of electroslag welding. The efficiency of electrode welding is low.Vertical electroslag welding of steel bars is better. Welding machine load rate is not less than 60%,However, welding machine at least 500A, the maximum can be welded 25 mm diameter steel bar,630A can weld steel bars of 32 millimeters in diameter.Welding efficiency of welding rod is low.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | |

| Main Markets | 40.00% Domestic Market 15.00% Mid East 10.00% South Asia 10.00% Southeast Asia 10.00% South America 5.00% Eastern Asia 5.00% Africa 5.00% North America |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Russian, Korean |

| b)Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Electrofusion Machine 20-315mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 6 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches