Automatic Linear Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Linear Edge Banding Machine

1. Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2. Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3. It adopt the imported original electrical machinery, each performance is better.

4. It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5. Blow up and down the side, surface polishing up and down and so on.

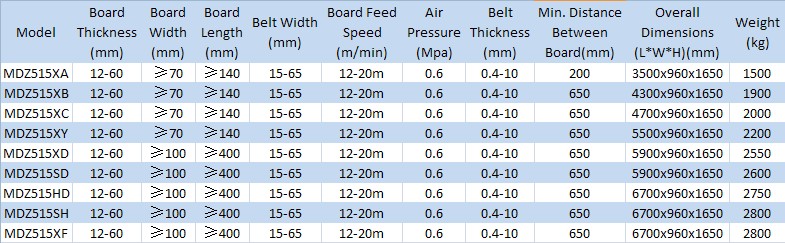

Specification of Automatic Linear Edge Banding Machine

Advantages of Automatic Linear Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

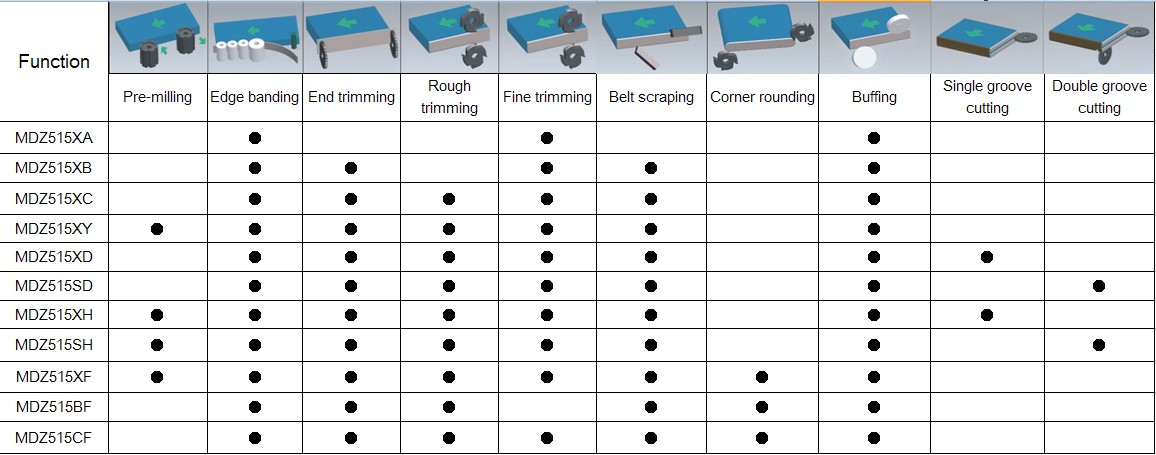

Main Functions of Automatic Linear Edge Banding Machine

Packing of Automatic Linear Edge Banding Machine

- Q:Integrated ceiling sealing edge role, not surrounded by edge can be?

- The aluminum buckle does not need glue to seal, one is the metal processing neat, the crevice is small and even, is not necessary, two is by the metal keel card, the assembly and disassembly is convenient, easy to open. Periphery also does not need to hit the rubber, hits is not good, but is ugly.

- Q:How about the east edge banding machine?

- Extremely East, liar! When buying, said he was South Korea imports, in fact, counterfeit domestic goods, not their own factoriesFortunately, it means three domestic brands. Please enjoy yourselfColleagues said Nan Xing woodworking, Yongqiang, Ma.

- Q:Custom wardrobe edge is not good, sunny taste is very heavy, I would like to use glass glue to wipe the corner of the side, do not know if it is feasible? The cabinet is a wall, knocking out the pity, have been more than a year, the winter is almost what have no taste, a sun is very smelly, but not pungent odor.

- Please refer to the classic distinction between "nail free glue" and "glass glue."It is recommended to use nail free gum:1, toughness bonding2, high strength: 3-6Mpa, high safety reserve3, it can be calculated:1 weight2, paste area3, shear capacity and safety reserve of adhesive (DrStik, no nail glue, 3-6Mpa)4, the back of the mirror is afraid of corrosion, and needs no corrosion free nail glue5, other considerations

- Q:PVC sealing strip extrusion foam what is the reason?

- In addition to some raw materials damp, containing more volatile will cause PVC edge banding in extrusion process will blister, there is a more prone to this phenomenon, namely: lack of thermal stability lead to PVC decomposition bubble. Lack of PVC thermal stability for several reasons: 1. heat stabilizer unqualified or improper selection; 2. heat stabilizer; 3. processing temperature setting is not reasonable, mainly temperature too high; 4. screw extruder of high speed; 5. formula system inside and outside lubrication or collocation unreasonable amount; 6. main raw materials such as stability PVC deficiency. In addition, reasonable mixing processing conditions will greatly reduce the volatile substances in raw materials.

- Q:The acquisition of a large number of furniture factory waste edge quality requirements Gaobutaiduomu ash can be who?

- Do you want to play wood ash? How much is it per ton? What about the contact details?

- Q:How to correctly use furniture edge hot melt adhesive

- The use of edge sealing adhesive should first be divided into machine, manual machine - low temperature edge banding adhesive. Semi automatic machine - medium temperature glue, automatic machine - high temperature edge banding glue; and there is to choose the appropriate glue according to the thickness of the edge banding, the season and environment will also affect the use of edge banding adhesive.

- Q:Where is the construction of the unsupported end plate in the 11G101-1P95 page?

- Personal understanding is that the thickness of the cantilever plate reinforcement should be banding structure, such as thickness > 150mm, raft raft out of the base, the cap width of the election, and so on. The 'unsupported board' is not very good.

- Q:Edge sealing machine, furniture, or paste the edge of furniture, good, what is the difference?

- You're talking about the production process, and the result is one thing.

- Q:What oil is added in the motor of the automatic edge sealing machine? How often do you add a motor with a belt? Is there a small hole on it?

- Oil with high viscosity can be substituted.

- Q:South Hing edge machine before the block after the action no action to repair block

- Without action, it is necessary to consider whether the cutter position sensor is out of order, whether the rear tool running limit stroke, the switch is faulty and whether the air control system is leaking or depressed. When maintaining, make sure the sensor resistance is within the normal range, the switch is opened and closed properly, and the gas path pressure is normal. If there is an exception, you can change the corresponding parts directly.Edge sealing machine is a kind of woodworking machinery, which belongs to solid wood machinery. The edge function complete face conveyor type of glue - cutting edge abnormity - block - up and down before and after trimming on the edge - finishing on scraping - polishing and many other processes.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Automatic Linear Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords