Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

(1) Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

(2) Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

(3)It adopt the imported original electrical machinery, each performance is better.

(4)It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

(5) Blow up and down the side, surface polishing up and down and so on.

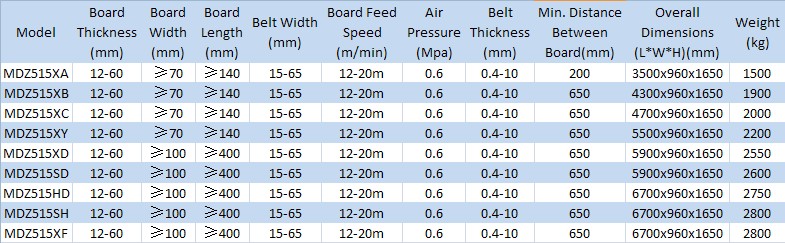

Specification

Advantages

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

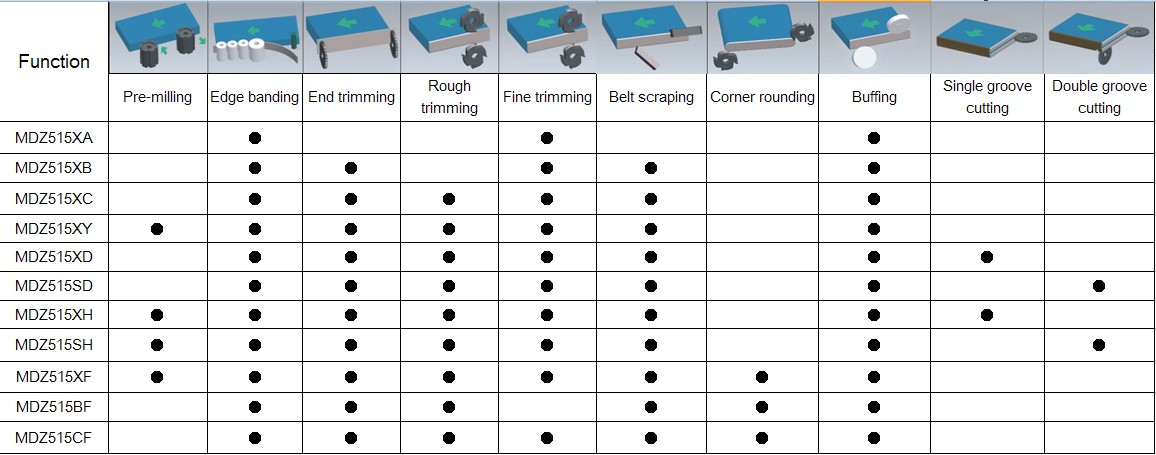

Main Functions

- Q:Hong Fei edge edge machine always stop machine

- No, my home Hongfei machine for several years, and the quality of their service or can. Personally, I think their service is ok.

- Q:Cabinet door panel edge strip off how to do?

- If a small area to buy 502 of it, a little bit on the stick, if the area is large, it is necessary to use monengjiao, with 502 wasted, my edge off a little bit, I used a 502 point fix.

- Q:Today I bought a set of cabinets, in order to forestry Jilin Lushuihe EO health specially selected the particleboard, particleboard on both sides but when construction workers in the marble table below the pad without edge, now feel that the taste is quite big, and the estimate is. Consult an expert, how do you do the edge banding for the shaving board? With solid wood edge strip or PVC or aluminum foil? With universal glue, you can reduce formaldehyde emissions to achieve the effect? Thank you very much!

- We usually use PVC, see my post, then to each plate aluminum trim slot coating

- Q:How to solve the panel furniture open non explosive edge ```PVC edge, how can I do not see the combination?

- Explosion. Side. Two reasons. One is bad is two sheet or blade is not good equipment.

- Q:Can the kitchen cabinet carbonization door plank do the acrylic edge banding? Optimistic about a set of kitchen cabinets, aluminum alloy plate, carbonized board. I don't like aluminum alloy hemming. Optimistic about color and brightness of carbonized board. Do not know the carbonized board is good to do acrylic edge?

- The landlord is a bit difficult, because the carbonization plate hardness is relatively high, with normal cutting devices to avoid cutting edge collapse, so usually used to wrap aluminum edge chipping, aluminum edge back hook part can cover up the small, if you want to use acrylic edge would need very good cutting equipment, and sealing machine requirements are relatively high, in the edge sealing machine before the first clear edge, also will bring the edge collapse, so unless there are special equipment manufacturers can do.

- Q:40Cm thick raft, straight through 12 steel double double direction, outer edge steel reinforcement length

- No less than 10 cm. Regular 15 centimeters will do

- Q:I recently want to decorate, take advantage of E0 class environmental protection solid wood paint free board, want to buy this kind of board, let people make cabinets, consult, buy back this kind of board, general carpentry master will do, need special equipment? Still need to make a special cabinet where the production? Especially the edge of this kind of plate, what kind of process is needed?

- Glue it, and there's a machine that automatically seals the edge. That machine is 2600

- Q:Leak is wood, especially ugly, is there a quality problem?

- This is OK, the door is loaded and you can't see it.

- Q:PVC edge banding process?

- General granulation, extrusion can be

- Q:What are the specifications of the side reinforcement in the raft edge construction? With gluten or gluten? Or using smaller steel bars?

- There are three kinds of edge sealing structures on the side and side of the plate foundation plate. One is the longitudinal reinforcement edge side edge structure, the other is the U rib structure edge banding way, and the three is the edge edge of the plate without the edge sealing structure, and the two is the edge structure of the plate edge.Many lateral reinforcing bars are of diameter 14mm or 16mm. The diameter and quantity of the reinforcement in the side structure are directly related to the thickness of the raft and the two-way main reinforcement

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b)Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords