Good Price Of Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Good Price Of Manual Edge Banding Machine

This Kind of Manual Edge Banding Machine is our main product of Edge Banding Machine Series. With comprehensive range ,it includes automatic edge banding machine, semi-auto edge banding machine ,automatic shaped edge banding machine and so on .As an important process in panel furniture and cabinet making process ,edge banding takes a great role in determining the quality ,price and level of furniture. Edge banding process will embellish the profile of furniture, protect the corner from wearing out, avoid the veneer lifting, while transferring and using. Besides, edge banding is also a way to proof water and harmful air, which may destroy our health .VE series edge banding machine is able to process chipboard, MDF board, and other manmade board with with PVC, melamine and veneer .We produce kinds of edge banding machines to meet different needs of our consumers .

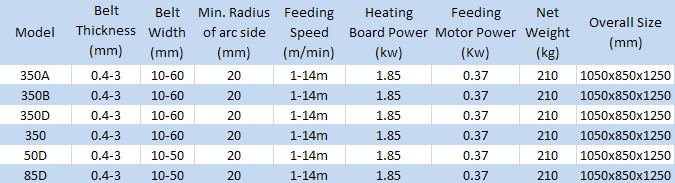

Specifications of Good Price Of Manual Edge Banding Machine

Advantages of Good Price Of Manual Edge Banding Machine

1. Easy operation.It can band the straight edge

2. Feedstock use the frequency transformer to adjust the speed

3. Having the auxiliary heating to ensure the glue flows smoothly

4. Woodworking Edge binding Machine with special design for glue systems, structural stability, long service life, coating uniformity and it will not leak glue

5. Multi-functional, can adapt to a variety of materials and sizes to provide a straight edge inside the arc, outside the arc, with curves and with circle

6. Automatically controls heat to reach set temperatures.Speed control can adjust banding speed to work at your pace

Package of Good Price Of Manual Edge Banding Machine

- Q:The difference with the closing edge?

- So is the diameter decreases; edge edge bluntness.

- Q:Hong Fei edge edge machine always stop machine

- No, my home Hongfei machine for several years, and the quality of their service or can. Personally, I think their service is ok.

- Q:There are two favorite bags are all genuine leatherThe black tape with straps on the shoulder doesn't know how it fell offOne is OK, the other is a bit seriousIt's sticky. It's a little longer on the back of your bag. It'll stick to black sticky glue on your clothesCheck it online and there's no solutionTo the special leather cleaning, cleaning shop also asked them, do not know how to doThe majority of users want to help me,The serious one is hilly's toilet bagWould you like to ask a friend who bought this bag to come across this situation?

- Use a leather of the same color to wrap up the problem. Although it doesn't start to look good, it's better than nothing.

- Q:I just touched furniture, this line, furniture edge, what should use glue, what glue good point.

- The furniture edge banding adhesive is a kind of adhesive specially used for sealing edges of artificial board. It is a solvent-free thermoplastic adhesive.Types of furniture edge banding adhesiveEVA (ethylene vinyl acetate copolymer resin) base hot melt adhesive, this hot melt adhesive can be divided into two types of filler and no filler. EVA as the base material is the most common furniture edge banding adhesive production technology, its main limitation is the poor heat resistance. With EVA hot melt adhesive edge of the use of plate furniture, ambient temperature can not be higher than 120 degrees C;POL YAMIDE (polyamide) based hot melt adhesive, which has excellent heat resistance and fast curing characteristics, the main drawback is expensive.HMPU (polyurethane) base hot melt adhesive, it is the best type of hot melt adhesive, high quality plate edge guarantee. It is expensive and requires a special method of use.

- Q:Why does our family seal edge fall off, cabinet experience deformation?

- A whole wardrobe is good, and its edge is also very important. Edge sealing is good, directly affect the cabinet deformation. Small manufacturers and small workshops are not, and basically the use of artificial sealing edge, sealing effect is poor, and even fall off, deformation, affecting the normal use of the wardrobe. I saw Elijah, edge line, edge machine good estimation.Cabinet deformation, then with the wardrobe plate, door frame and so on, as well as the assembly is not closely related. In small factories or small workshops produced wardrobe, prone to Jerry built, wardrobe panels, door frames thickness does not meet the standards, assembly does not meet the specifications, and even cabinet size is too large or small. So out of the so-called whole wardrobe, of course, may be deformed and twisted.

- Q:I do Aluminum Alloy edge cabinets with more but do not know what a good play I've been playing rubber sealant but I found people playing is a kind of transparent glue and dry hard also do not know what is the glue please help thank you.There is aluminum alloy edge banding, how can you precisely cut 45 degrees angle, I cut all right, not very good mouth how to do, there are burrs on the incision?.

- The edge of modern furniture parts along the edge of a common processing method, the best use of manual edge special glue edge, does not recommend the use of adhesive, heat is easy to fall off. The aluminum alloy sealing edge on the cabinet door should choose environmental protection and healthy glue, for example, glue of German glue king. Ordinary glue contains a large amount of formaldehyde, used in furniture which has great harm to the body, while glue king is environmental protection glue, reaching the highest environmental testing standards.

- Q:I don't know now that the temperature on the temperature of the 1. granulation will directly affect the quality of the material are 2. high temperature will how low will how 3. material and what are the differences between the 4. side of the extrusion temperature how to master? 5. why is the material very crisp, what is the reason?

- You should have material things will evaporate, also did not control the processing temperature, the high temperature will brittle, PVC plastic processing is the best speed as fast as possible, temperature is as low as possible, only in the extrusion die head can be slightly higher, make the surface smooth

- Q:Edge sealing machine, furniture, or paste the edge of furniture, good, what is the difference?

- On the whole, it doesn't make any difference. It depends on how other people make it. Is it artificial or machine?. In fact, the two are simply a truth, there is no comparable

- Q:What is the difference between cutting edge plate and its own processing?

- Machine edge is certainly much than manual edge banding machine edge is strong, the first special hot melt adhesive, sealing with adhesive only

- Q:South Hing edge machine before the block after the action no action to repair block

- Without action, it is necessary to consider whether the cutter position sensor is out of order, whether the rear tool running limit stroke, the switch is faulty and whether the air control system is leaking or depressed. When maintaining, make sure the sensor resistance is within the normal range, the switch is opened and closed properly, and the gas path pressure is normal. If there is an exception, you can change the corresponding parts directly.Edge sealing machine is a kind of woodworking machinery, which belongs to solid wood machinery. The edge function complete face conveyor type of glue - cutting edge abnormity - block - up and down before and after trimming on the edge - finishing on scraping - polishing and many other processes.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shunde; Guangzhou |

| Export Percentage | 5% - 10% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Good Price Of Manual Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords