CNC Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of CNC Automatic Edge Banding Machine

(1) Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

(2) Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

(3)It adopt the imported original electrical machinery, each performance is better.

(4)It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

(5) Blow up and down the side, surface polishing up and down and so on.

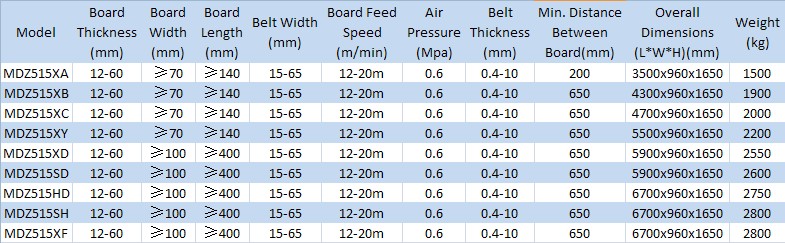

Specification of CNC Automatic Edge Banding Machine

Advantages of CNC Automatic Edge Banding Machine

1. Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2. The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3. End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4. Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5. Profiling unit, to make board end smooth and aesthetic.

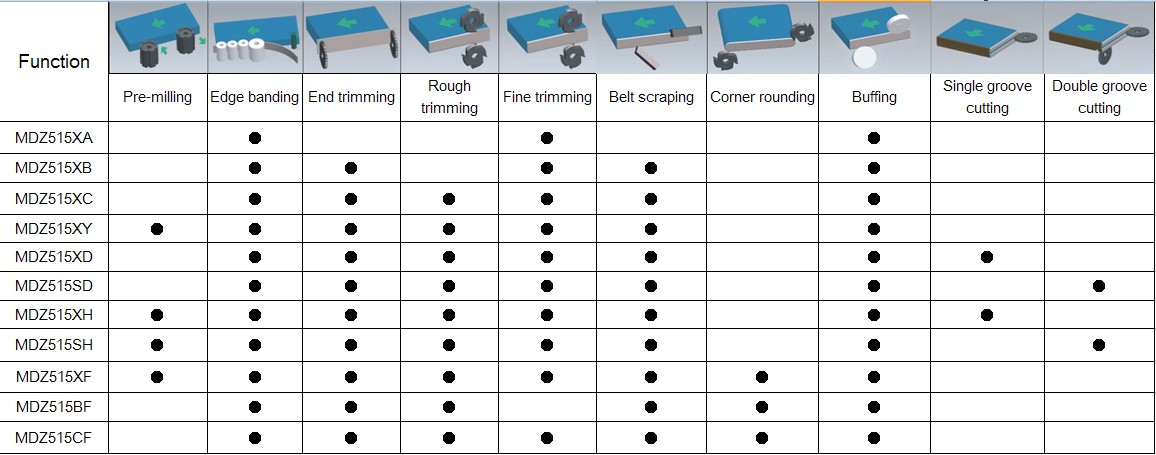

Main Functions of CNC Automatic Edge Banding Machine

Packing of CNC Automatic Edge Banding Machine

- Q:Ask everybody a thing, how much is that cloth sealing edge strip one meter?

- Hello, which kind of edge banding do you prefer, solid wood or PVC? What are the width and thickness?,

- Q:Why should there be banding reinforcement? In which case are edge reinforcement bars calculated?

- The construction of edge reinforcement is usually required by the construction and the force of the structure.Most of the reinforcing bars appear at the end of the non supporting plate, such as the end of the cantilever plate

- Q:Integrated ceiling sealing edge role, not surrounded by edge can be?

- Periphery must use the edge banding, these all are the matching use, for is beautiful looks, moreover also facilitates the gusset plate to close.

- Q:Cabinet, quartz stone mesa with what edge?

- Can not stainless steel, can also come to collect the edge of the white porcelain.

- Q:Arc platform how edge? Urgently!!!

- My house is platform of arc, as is the use of solid wood board, so the platform is on the edge of the floor slightly out of one centimeter, put out the floor into the arc, edge grinding can be, no seal, I wonder if this method is suitable for you?

- Q:9 eco plates can edge it?

- The edge banding strip is a kind of material used to protect, decorate and beautify the section of furniture and plate. It can make the furniture appear clear and colorful. If the process is good, the problem is not large. Of course, eco board and edge banding still have to choose a bit of it, with so much effort, can not be quickly broken. Good steel used in the blade, to the quality of materials, decorative building materials collection site to buy some good material, and use it is also save effort.

- Q:I am a furniture factory, need a lot, it is best to paint to dry is the best, the ash inside the shop, if the dry time is too slow for local repair will be dust, it will look at the dust, affect the quality of the product.

- Or engage in equipment, see what reason end edge after the show mainly has several aspects, one is only one side of the saw, if it is open at the end, you saw the small saw blade is too high, it low, or with a pre wash milling is good, if the two sides open at the end, it is too big to glue look, what reason, if it is winter, due to low environmental temperature, glue just painted on the solidification, the pressure is not real, for glue, stick firmly, installing plate preheating device can solve the problem, the problem is not winter, edge glue painted edgeband sub pressure wheel pressure is not enough no, pressure, or your gum is not good quality, short solidification time, low temperature may also glue you to adjust, will cause this situation. If your edgeband side open at the end, it is your problem finishing knife adjustment, adjustment is too large, it is good to adjust

- Q:Method for using small-sized edge banding machine

- 1. Turn on the power before checking whether the switch is in the closed position. Close the trimming and turn the heating switch on the right to make it work.2, the edge belt is arranged on the rotating disc edge is greater than the thickness of 3-4MM, otherwise edgeband can not completely seal plate, there will be a period of above or below the seams phenomenon, the edge by hand pressure with five-star lever into the scissors seat, front and rear belt pressing lever presses down edgeband not too tight, not too loose, too tight edgeband cannot pass through the pressure rod, loose edge will appear in front of or behind the phenomenon of deviation.3, before the start of the work to see if the melt has been melted, and then send the material size of the pressure modulation plate thickness, size, start the transfer switch, check the amount of sizing, and whether it is suitable for working conditions.

- Q:Which is better, the furniture edge, the button strip and the edge banding strip?

- Each one has his good points, edging good-looking but easy to fall off; buckle out but firm bonding

- Q:What is the difference between cutting edge plate and its own processing?

- The machine presses the edge bar and the plate firmly together through the air pressure, and the handwork can not reach the machine. The effect of the trimming is perfect

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai, China |

| Year Established | 1995 |

| Annual Output Value | US$ 150 Million |

| Main Markets | 30.00% Europe 40.00% North America 30.00% Southeast Asia; Mid East |

| Company Certifications | CE; ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

CNC Automatic Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords