All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

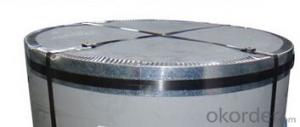

- - Electrolytic Tinplate Coil

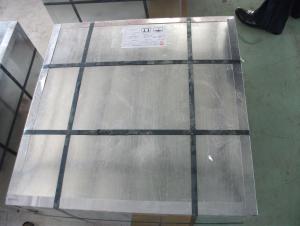

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does electrolytic tinplate coil compare to other tin coatings in terms of quality and performance?

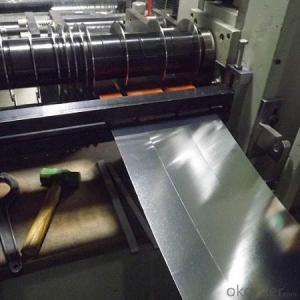

Electrolytic tinplate coil is generally considered to be superior in terms of quality and performance compared to other tin coatings. It offers enhanced corrosion resistance, excellent adhesion, and a smooth and uniform surface. Additionally, the electrolytic tinplate coil provides better solderability and is widely used in various industries such as packaging, automotive, and electronics.

What are the common surface treatments used to improve the adhesion of electrolytic tinplate coil?

Some common surface treatments used to improve the adhesion of electrolytic tinplate coil include degreasing, pickling, electrolytic cleaning, and application of chemical conversion coatings. These treatments help remove contaminants, promote surface activation, and enhance the bonding between the tin and the base metal of the coil.

What are the potential factors that can cause tinplate coil to exhibit poor thermal conductivity?

Some potential factors that can cause tinplate coil to exhibit poor thermal conductivity include the presence of impurities or contaminants in the tin coating, inadequate surface preparation before coating, improper heat treatment or annealing processes, and excessive thickness or unevenness of the tin coating. Additionally, factors such as poor contact between the tinplate coil and the heat source, oxidation of the tin coating, and the presence of insulating materials between the coil and the heat source can also contribute to poor thermal conductivity.

Can electrolytic tinplate coil be used in the production of metal beer caps?

Yes, electrolytic tinplate coil can be used in the production of metal beer caps.

Can electrolytic tinplate coil be recycled?

Yes, electrolytic tinplate coil can be recycled. Tinplate is a valuable material that can be recovered and reused through recycling processes. Recycling the tinplate coil not only helps to conserve natural resources but also reduces waste and environmental impact.

Wholesale Electrolytic Tinplate Coil from supplier in Haiti

With our expertise in supplying Electrolytic Tinplate Coils, we can cater to the diverse needs of customers in Haiti. Whether you require sales, quotations, or technical support, our team is dedicated to providing top-notch service. As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver comprehensive procurement services for Electrolytic Tinplate Coils in Haiti.

Our extensive product range ensures that we can meet your specific requirements, no matter the scale of your project. We understand the unique challenges and opportunities of the Haitian market, thanks to our years of experience operating in the region. This market experience allows us to offer valuable insights and guidance to our customers.

Whether you are embarking on small-scale projects or large-scale ventures, we are well-equipped to assist you. Our team of experts is committed to providing the expertise and assistance you need to achieve your goals. With our reliable supply chain and dedication to customer satisfaction, you can trust us to be your preferred supplier of Electrolytic Tinplate Coils in Haiti.

Our extensive product range ensures that we can meet your specific requirements, no matter the scale of your project. We understand the unique challenges and opportunities of the Haitian market, thanks to our years of experience operating in the region. This market experience allows us to offer valuable insights and guidance to our customers.

Whether you are embarking on small-scale projects or large-scale ventures, we are well-equipped to assist you. Our team of experts is committed to providing the expertise and assistance you need to achieve your goals. With our reliable supply chain and dedication to customer satisfaction, you can trust us to be your preferred supplier of Electrolytic Tinplate Coils in Haiti.