All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

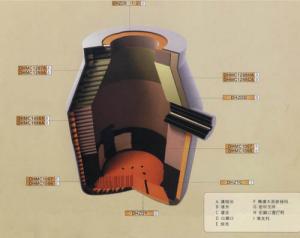

What are the common refractory materials used in cement kilns?

The common refractory materials used in cement kilns include high-alumina bricks, fireclay bricks, and basic refractories such as magnesia bricks. These materials are chosen for their high temperature resistance, ability to withstand chemical reactions, and durability in the harsh conditions of the cement kiln.

What are the refractory materials used in the automotive industry?

Refractory materials commonly used in the automotive industry include ceramics, high-temperature alloys, and composites. These materials are chosen for their ability to withstand extreme heat and provide insulation in various automotive applications such as engine components, exhaust systems, and braking systems.

How are refractory castables used in construction?

Refractory castables are used in construction as a versatile and durable material for lining high-temperature equipment such as furnaces, kilns, and incinerators. They can be shaped and molded to fit any desired design, providing insulation and protection against extreme heat, corrosion, and thermal shocks. Refractory castables are typically made from a mixture of refractory aggregates, binders, and additives, which are carefully selected and proportioned to meet specific application requirements. Once applied, these castables are heated to form a strong and resistant lining that ensures optimal performance and longevity of the constructed equipment.

Wholesale Refractory Materials from supplier in Haiti

Our team of experts can assist you in selecting the right refractory materials for your specific applications, ensuring optimal performance and durability. We offer a wide range of refractory products, including bricks, castables, mortars, and insulation materials, all of which are sourced from reliable manufacturers and suppliers.

In addition to supplying refractory materials, we also provide sales support services, including competitive pricing and timely delivery. Our quoting services help you obtain accurate and transparent pricing for your projects, ensuring cost-effectiveness and budget control.

Furthermore, our technical support team is available to assist you throughout the entire project process. From initial consultation to installation and maintenance, we provide guidance and expertise to ensure that your refractory materials are used correctly and efficiently. Our team can also offer on-site training and technical assistance, helping you optimize the performance of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your refractory material needs in Haiti. CNBM is a renowned leader in the construction industry, with a strong focus on innovation and sustainability. By partnering with us, you can benefit from our extensive market presence and industry knowledge.

At our company, customer satisfaction is our top priority. We strive to provide a seamless experience for our customers, offering comprehensive solutions and personalized support. Whether you are working on a small-scale project or a large-scale industrial application, we are committed to delivering high-quality refractory materials and exceptional service.

Contact us today to learn more about our refractory materials and services in Haiti. We look forward to partnering with you and contributing to the success of your projects.

In addition to supplying refractory materials, we also provide sales support services, including competitive pricing and timely delivery. Our quoting services help you obtain accurate and transparent pricing for your projects, ensuring cost-effectiveness and budget control.

Furthermore, our technical support team is available to assist you throughout the entire project process. From initial consultation to installation and maintenance, we provide guidance and expertise to ensure that your refractory materials are used correctly and efficiently. Our team can also offer on-site training and technical assistance, helping you optimize the performance of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to meet your refractory material needs in Haiti. CNBM is a renowned leader in the construction industry, with a strong focus on innovation and sustainability. By partnering with us, you can benefit from our extensive market presence and industry knowledge.

At our company, customer satisfaction is our top priority. We strive to provide a seamless experience for our customers, offering comprehensive solutions and personalized support. Whether you are working on a small-scale project or a large-scale industrial application, we are committed to delivering high-quality refractory materials and exceptional service.

Contact us today to learn more about our refractory materials and services in Haiti. We look forward to partnering with you and contributing to the success of your projects.

Hot Search

- Monolithic Refractories in Malawi

- Ceramic Fiber Products in Germany

- Refractory Bricks in Bengal

- Raw Materials For Refractory in Turkey

- Raw Materials For Refractory in Nicaragua

- Raw Materials For Refractory in Comoros

- Monolithic Refractories in Kenya

- Monolithic Refractories in Sudan

- Raw Materials For Refractory in Colombia

- Ceramic Fiber Products in Ethiopia