All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

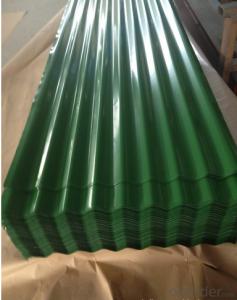

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are in place to maintain coil flatness during storage and handling?

There are several measures in place to maintain coil flatness during storage and handling. Firstly, coils are typically stored in a horizontal position to distribute the weight evenly and prevent any sagging or deformation. Additionally, special handling equipment, such as coil lifters or cranes, are used to minimize any bending or twisting forces applied to the coils during transportation. Moreover, protective packaging materials, such as wooden skids or plastic wrapping, are utilized to prevent any external pressure or impact that could cause coil distortion. Regular inspections and quality control checks are also conducted to identify and correct any potential flatness issues before they become significant. Overall, these measures ensure that coils remain flat and in optimal condition throughout storage and handling processes.

What measures are taken to ensure coil gauge consistency when manufacturing automotive safety equipment?

To ensure coil gauge consistency when manufacturing automotive safety equipment, several measures are typically taken. First, strict quality control protocols and standardized processes are implemented throughout the manufacturing process. This includes regular inspection and testing of the coil gauge to ensure it meets the required specifications.

Additionally, specialized machinery and equipment are used to accurately measure and monitor the coil gauge during production. This helps to identify any deviations or inconsistencies, allowing for immediate corrective actions to be taken.

Moreover, comprehensive training programs are provided to the manufacturing personnel involved in the production of automotive safety equipment. This ensures that they are well-versed with the specific requirements and techniques for maintaining coil gauge consistency.

Overall, a combination of quality control procedures, advanced measurement tools, and skilled workforce contribute to maintaining coil gauge consistency during the manufacturing of automotive safety equipment.

How are steel coils transported for international shipping?

Steel coils are typically transported for international shipping using specialized shipping containers or vessels. These containers are designed to safely accommodate the weight and dimensions of the steel coils. They are loaded onto flatbed trucks or railcars and transported to the port. At the port, they are then loaded onto a container ship or a specialized vessel equipped with cranes for efficient loading and unloading. The steel coils are secured in place to prevent any movement during transit and ensure their safety during international shipping.

Wholesale Steel Coils from supplier in Bangladesh

We understand the importance of quality and reliability in the steel industry, which is why we only source our steel coils from trusted manufacturers. Our products undergo rigorous quality control processes to ensure they meet the highest standards.

Our sales team is dedicated to providing excellent customer service and prompt responses to inquiries. Whether you need a quote or technical support, our team is here to assist you every step of the way.

In addition to our sales and technical support services, we also offer logistics and delivery assistance. We understand that timely delivery is crucial for your projects, and we work closely with reliable shipping partners to ensure your steel coils are delivered on time and in good condition.

At CNBM, we believe in building long-term relationships with our clients. We strive to exceed your expectations and provide you with the best possible solutions for your steel coil needs in Bangladesh. Contact us today to discuss your requirements and let us be your trusted supplier of steel coils.

Our sales team is dedicated to providing excellent customer service and prompt responses to inquiries. Whether you need a quote or technical support, our team is here to assist you every step of the way.

In addition to our sales and technical support services, we also offer logistics and delivery assistance. We understand that timely delivery is crucial for your projects, and we work closely with reliable shipping partners to ensure your steel coils are delivered on time and in good condition.

At CNBM, we believe in building long-term relationships with our clients. We strive to exceed your expectations and provide you with the best possible solutions for your steel coil needs in Bangladesh. Contact us today to discuss your requirements and let us be your trusted supplier of steel coils.