All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the width of a steel coil impact its suitability for specific manufacturing processes?

The width of a steel coil directly impacts its suitability for specific manufacturing processes. A wider coil allows for larger and more complex parts to be produced, making it suitable for applications that require greater strength and structural integrity. On the other hand, a narrower coil is better suited for processes that require precision and tight tolerances, such as forming small components or intricate shapes. Therefore, the width of a steel coil plays a crucial role in determining its compatibility with different manufacturing processes.

How is coil width determined in the manufacturing of automotive components?

Coil width in the manufacturing of automotive components is determined based on several factors, including the specific design requirements of the component, the intended application, and the available machinery and equipment. The coil width is carefully calculated to ensure optimal material utilization and production efficiency while meeting the desired specifications and quality standards.

How are steel coils inspected for oil residue before further processing?

Steel coils are inspected for oil residue before further processing through a combination of visual inspection and specific testing methods. Visual inspection involves examining the surface of the coils for any visible signs of oil residue. Additionally, various testing methods such as wipe tests or solvent extraction are used to collect samples from the coils and analyze them for the presence of oil residue. These inspections help ensure that the coils are free from any oil contamination before they undergo further processing.

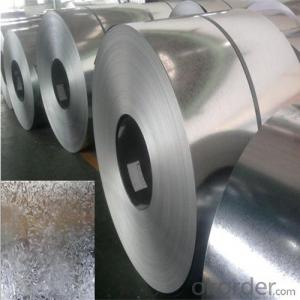

Wholesale Steel Coils from supplier in Haiti

We understand the importance of reliable and high-quality Steel Coils for your projects in Haiti. As a trusted supplier, we guarantee the durability and performance of our products. Our Steel Coils are manufactured using advanced technology and adhere to international quality standards.

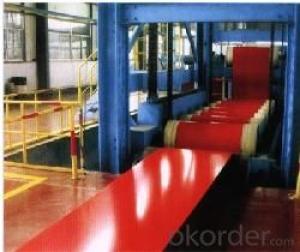

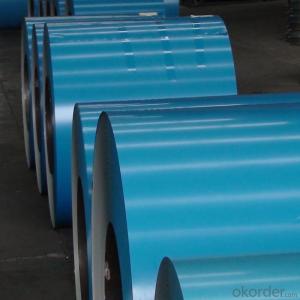

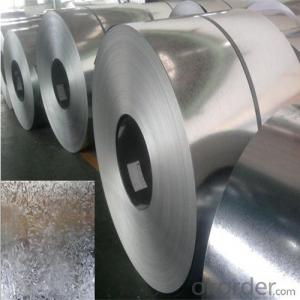

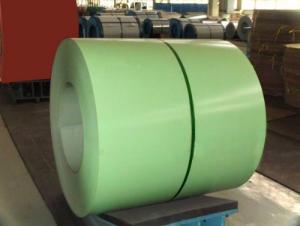

We offer a wide range of Steel Coils, including hot-rolled, cold-rolled, galvanized, and pre-painted coils. Our coils are available in various sizes, thicknesses, and finishes to suit your specific requirements. Whether you need coils for construction, manufacturing, or any other application, we have the right solution for you.

In addition to our comprehensive product range, we provide a range of value-added services to ensure a seamless procurement experience. Our dedicated team is available to assist you at every step, from initial inquiry to post-sales support. We can provide technical guidance, assist with product selection, and offer competitive pricing to help you achieve your project goals.

As a subsidiary of CNBM, we have access to a global network of suppliers and resources. This allows us to offer competitive pricing and ensure a consistent supply of Steel Coils to meet your demands. Our efficient logistics and distribution system enable us to deliver your orders on time, regardless of the quantity or location.

We are committed to sustainability and environmental responsibility. Our Steel Coils are manufactured using eco-friendly processes, minimizing the impact on the environment. We prioritize the use of recycled materials and promote energy-efficient production methods.

Partner with us as your preferred Steel Coils supplier in Haiti, and benefit from our extensive product range, market expertise, and exceptional customer service. Contact us today to discuss your requirements and experience the difference of working with a reliable and trusted supplier.

We offer a wide range of Steel Coils, including hot-rolled, cold-rolled, galvanized, and pre-painted coils. Our coils are available in various sizes, thicknesses, and finishes to suit your specific requirements. Whether you need coils for construction, manufacturing, or any other application, we have the right solution for you.

In addition to our comprehensive product range, we provide a range of value-added services to ensure a seamless procurement experience. Our dedicated team is available to assist you at every step, from initial inquiry to post-sales support. We can provide technical guidance, assist with product selection, and offer competitive pricing to help you achieve your project goals.

As a subsidiary of CNBM, we have access to a global network of suppliers and resources. This allows us to offer competitive pricing and ensure a consistent supply of Steel Coils to meet your demands. Our efficient logistics and distribution system enable us to deliver your orders on time, regardless of the quantity or location.

We are committed to sustainability and environmental responsibility. Our Steel Coils are manufactured using eco-friendly processes, minimizing the impact on the environment. We prioritize the use of recycled materials and promote energy-efficient production methods.

Partner with us as your preferred Steel Coils supplier in Haiti, and benefit from our extensive product range, market expertise, and exceptional customer service. Contact us today to discuss your requirements and experience the difference of working with a reliable and trusted supplier.