All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

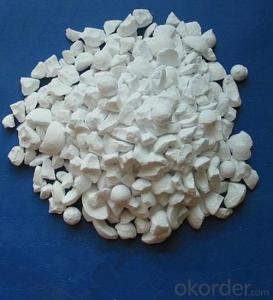

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do ultra-high-temperature refractories withstand extreme heat and chemical environments?

Ultra-high-temperature refractories are specifically designed to withstand extreme heat and harsh chemical environments due to their unique composition and structure. These refractories are made using advanced materials such as ceramics, carbon, and silicon carbide, which possess high melting points and excellent thermal stability. They are engineered to have low porosity, high density, and superior chemical resistance, allowing them to maintain their structural integrity even when exposed to intense heat and corrosive substances. Additionally, these refractories undergo rigorous manufacturing processes, including sintering and impregnation, to enhance their thermal conductivity and strength. Overall, their exceptional material properties and specialized fabrication techniques enable ultra-high-temperature refractories to endure and perform reliably in extreme heat and chemical conditions.

How does the particle size of raw materials affect refractory properties?

The particle size of raw materials can significantly impact the refractory properties. Smaller particle sizes often lead to better packing and densification, resulting in improved mechanical strength and reduced porosity. Additionally, smaller particles allow for increased surface area and better contact between particles, promoting stronger bonding and enhanced thermal conductivity. However, excessively fine particles can increase the risk of sintering and reduce permeability, while larger particles may lead to poor particle packing and decreased mechanical strength. Therefore, careful control of particle size distribution is crucial for achieving desired refractory properties.

What are the sources of high-quality dolomite for refractory use?

Some sources of high-quality dolomite for refractory use include natural dolomite deposits, quarries, and mines. These sources provide dolomite that has a high purity level and is suitable for use in refractory applications. Additionally, dolomite can also be produced synthetically through processes like calcination and sintering, ensuring a consistent and high-quality product for refractory purposes.

Which refractory raw materials have good resistance to alkalis?

Some refractory raw materials that have good resistance to alkalis include chrome magnesite, mullite, and zirconia.

Wholesale Raw Materials For Refractory from supplier in Cambodia

Whether you need assistance with product selection, technical guidance, or after-sales service, we are here to provide you with the highest level of support. Our team of experts is knowledgeable about the latest industry trends and can help you find the most suitable raw materials for your specific applications.

We understand the importance of timely delivery and strive to ensure that your orders are fulfilled promptly. With our efficient logistics network, we can deliver raw materials to your doorstep in Cambodia, ensuring a hassle-free experience for you.

As a reputable supplier, we are committed to maintaining the highest standards of quality. All our raw materials for refractory undergo rigorous testing and quality control procedures to ensure their performance and durability. We work closely with our manufacturing partners to ensure that our products meet international standards and specifications.

Whether you are involved in construction, manufacturing, or any other industry that requires refractory materials, we can provide you with the solutions you need. Partner with us and experience the benefits of working with a trusted supplier of raw materials for refractory in Cambodia.

Contact us today to discuss your requirements and let us assist you in finding the best solutions for your projects. We look forward to serving you and contributing to the success of your business in Cambodia.

We understand the importance of timely delivery and strive to ensure that your orders are fulfilled promptly. With our efficient logistics network, we can deliver raw materials to your doorstep in Cambodia, ensuring a hassle-free experience for you.

As a reputable supplier, we are committed to maintaining the highest standards of quality. All our raw materials for refractory undergo rigorous testing and quality control procedures to ensure their performance and durability. We work closely with our manufacturing partners to ensure that our products meet international standards and specifications.

Whether you are involved in construction, manufacturing, or any other industry that requires refractory materials, we can provide you with the solutions you need. Partner with us and experience the benefits of working with a trusted supplier of raw materials for refractory in Cambodia.

Contact us today to discuss your requirements and let us assist you in finding the best solutions for your projects. We look forward to serving you and contributing to the success of your business in Cambodia.

Hot Search

- Monolithic Refractories in Iran

- Ceramic Fiber Products in Germany

- Refractory Bricks in Dominica

- Raw Materials For Refractory in Romania

- Ceramic Fiber Products in Papua New Guinea

- Raw Materials For Refractory in Togo

- Refractory Bricks in Switzerland

- Monolithic Refractories in Russia

- Raw Materials For Refractory in Tunisia

- Monolithic Refractories in Norway