All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

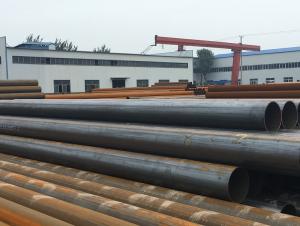

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different heat treatment inspection requirements for seamless steel pipe?

The different heat treatment inspection requirements for seamless steel pipe include checking for proper heat treatment cycles, examining the microstructure of the steel, measuring the hardness of the material, conducting non-destructive testing such as ultrasonic or radiographic examination, and verifying the mechanical properties of the pipe. Additionally, visual inspection is also performed to detect any surface defects or abnormalities in the heat treated steel pipe.

How is seamless steel pipe used in the automotive industry?

Seamless steel pipes are extensively used in the automotive industry for various applications. They are commonly used in the manufacturing of exhaust systems, engine components, and fuel injection systems. The seamless nature of these pipes ensures higher strength, durability, and resistance to corrosion, which are crucial in automotive applications. Additionally, seamless steel pipes are preferred for their ability to withstand high temperatures and pressure, making them suitable for transporting fluids and gases in vehicles.

Can seamless steel pipes be used for sewage systems?

Yes, seamless steel pipes can be used for sewage systems. They are known for their durability, strength, and resistance to corrosion, making them suitable for handling wastewater and sewage materials. Additionally, their seamless construction eliminates the risk of leakage, ensuring efficient and reliable functioning of the sewage system.

What is the difference between seamless steel pipes and welded steel pipes?

The main difference between seamless steel pipes and welded steel pipes lies in their manufacturing process. Seamless steel pipes are produced by piercing a solid steel billet, while welded steel pipes are made by welding together two or more steel plates or coils. This distinction results in differences in their strength, appearance, and ability to withstand pressure. Seamless pipes have uniform strength throughout their structure and are generally considered stronger and more reliable. Welded pipes, on the other hand, may have weaker spots due to the welding process, but they are more cost-effective and readily available. Additionally, seamless pipes have a smoother interior surface, making them more suitable for high-pressure applications, while welded pipes are typically used for low to medium-pressure applications.

Wholesale Seamless Steel Pipe from supplier in Cambodia

Our team is ready to provide you with a seamless steel pipe solution tailored to your specific needs. We understand the unique requirements of the Cambodian market and are committed to delivering the highest quality products and services.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to offer a comprehensive range of seamless steel pipe products and services at competitive prices.

Our dedicated team is available to assist you throughout the entire procurement process. From sales and quotation to technical support, we will ensure that your needs are met with efficiency and professionalism.

With our extensive market knowledge and experience in Cambodia, we can provide valuable insights and guidance to ensure the success of your projects. Whether you are in need of seamless steel pipes for construction, infrastructure, or industrial applications, we have the expertise and product range to meet your requirements.

Partnering with us means having a reliable and trusted supplier for all your seamless steel pipe needs in Cambodia. We are committed to delivering exceptional service, high-quality products, and valuable expertise to support your projects.

Contact us today to discuss your seamless steel pipe needs and discover how we can assist you. We look forward to working with you and providing you with the best solution for your specific requirements.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to extensive resources and expertise. This allows us to offer a comprehensive range of seamless steel pipe products and services at competitive prices.

Our dedicated team is available to assist you throughout the entire procurement process. From sales and quotation to technical support, we will ensure that your needs are met with efficiency and professionalism.

With our extensive market knowledge and experience in Cambodia, we can provide valuable insights and guidance to ensure the success of your projects. Whether you are in need of seamless steel pipes for construction, infrastructure, or industrial applications, we have the expertise and product range to meet your requirements.

Partnering with us means having a reliable and trusted supplier for all your seamless steel pipe needs in Cambodia. We are committed to delivering exceptional service, high-quality products, and valuable expertise to support your projects.

Contact us today to discuss your seamless steel pipe needs and discover how we can assist you. We look forward to working with you and providing you with the best solution for your specific requirements.