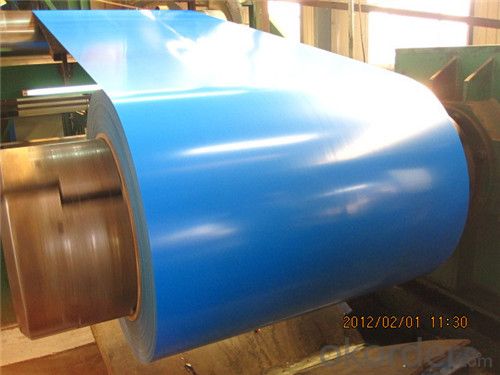

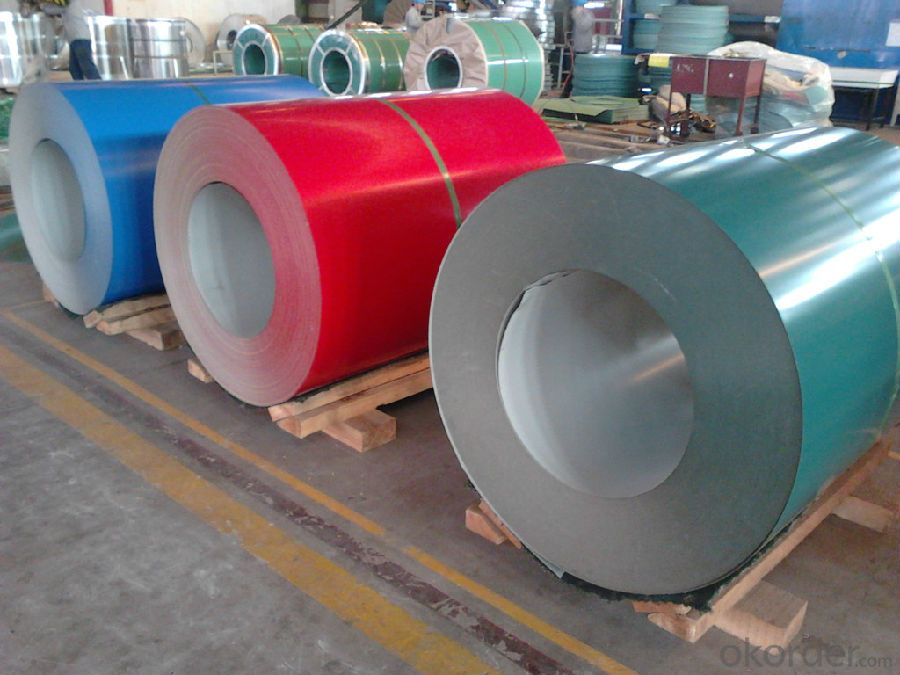

Z49 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z49 BMP Prepainted Rolled Steel Coil for Construction

Description of Z49 BMP Prepainted Rolled Steel Coil for Construction

Cold rolled steel coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold rolled steel coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The cold rolled steel coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the cold rolled steel coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final cold rolled steel coil may be manufactured in the form of sheets, strips, bars, or other forms.

Main Feature of Z49 BMP Prepainted Rolled Steel Coil for Construction

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3. Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle East, the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Applications of Z38 BMP PPGI Prepainted Rolled Steel Coil for Construction

1. Construction and building: Roofing; Ventilating duct; Handrail; Partition panel, etc.

2. Further processing: Coating base plate.

3. Electric appliance: Refrigerator; Washing machine; Recorder; Microwave, etc.

Specifications of Z49 BMP Prepainted Rolled Steel Coil for Construction

Product | Z49 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z49 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel coil cutting methods?

- There are several different types of steel coil cutting methods, including shearing, slitting, and laser cutting. Shearing involves using a straight blade to cut through the coil, while slitting involves using circular blades to make multiple cuts. Laser cutting is a more precise method that uses a laser beam to cut through the coil. Each method has its advantages and is chosen based on the specific requirements of the project.

- Q: What are the different types of coil leveling machines?

- There are three main types of coil leveling machines: precision levelers, corrective levelers, and stretcher levelers.

- Q: What are the different methods of tension leveling for steel coils?

- There are several methods of tension leveling for steel coils, each with its own advantages and applications. 1. Roller leveling: This method involves passing the steel coil through a series of rollers under high tension. The rollers are strategically positioned to apply pressure on the coil, effectively stretching and elongating it. Roller leveling is commonly used for thinner gauge coils and is effective in removing coil set, crossbow, and edge wave defects. 2. Stretch leveling: In this method, the steel coil is subjected to a combination of tension and elongation. The coil is gripped by clamps at both ends and then stretched using hydraulic or mechanical devices. This process helps to remove residual stresses, flatten the coil, and improve shape control. Stretch leveling is particularly suitable for thicker gauge coils and can effectively eliminate wavy edges and center buckle. 3. Temper rolling: This method involves passing the steel coil through a series of temper rolls, which apply pressure on the surface of the coil. Temper rolling is primarily used to improve the surface finish of the steel and enhance its mechanical properties. It can also help to reduce coil set and improve flatness. 4. Skin pass rolling: In this method, the steel coil is passed through a series of rolls that apply a light pressure on the surface. Skin pass rolling is typically performed after the primary leveling process to further improve surface finish, enhance flatness, and reduce surface defects such as scratches or marks. 5. Stretcher leveling: This method involves clamping the steel coil at both ends and then applying tension to stretch it. The stretched coil is then held in this position for a period of time to allow for stress relief and shape correction. Stretcher leveling is commonly used for thicker gauge coils and can effectively remove coil set, crossbow, and center buckle. Each of these tension leveling methods offers unique advantages and is suitable for different types of steel coils and specific requirements. The choice of method depends on factors such as coil thickness, desired flatness, surface finish, and the specific defects that need to be corrected.

- Q: Does anyone know what is 12 gage Cold Rolled Steel meaning? Also, help me to describe it.Thank you so muck ~!Mark Lin

- Steel thickness is measured by gages. 16 gage is approximately 1/16th of an inch. The larger the number (say, 24), the thinner the steel. Steel is made from large metal bars (4'x12', about 8 thick) that pass through presses to get thinner and thinner. If the final stages of rolling are done with pressure and not heat, it is cold rolled. It often gets galvanized to prevent rusting. Hope this helps.

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: What are the dimensions of steel coils used in the building materials industry?

- The specific application and requirements determine the varying dimensions of steel coils in the building materials industry. Typically, steel coils in this industry have a thickness ranging from 0.5mm to 3mm and a width ranging from 600mm to 1500mm. The length of the coil can vary based on the manufacturer and customer specifications. It is important to note that the weight of the coil also varies, with typical weights ranging from a few hundred kilograms to several tonnes, depending on the size and thickness of the coil. Ultimately, the dimensions of steel coils in the building materials industry are determined by the specific needs and specifications of the intended construction projects.

- Q: What is future prospect of these steel structures, are they really weather proof like everyone believes??

- you are doubting the steel structure building? Well, not every compay can give the same steel building, come to Muyang, it can give you best steel structure building.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: How are steel coils inspected for hardness using hardness testers?

- To assess the strength and durability of steel coils, hardness testers are employed to examine their hardness. Hardness testers are specialized devices used to gauge a material's resistance to indentation or penetration. For steel coils, Rockwell or Brinell testers are commonly utilized. Both methods entail exerting a precise force onto the surface of the coil and measuring the depth of indentation or size of the impression made. In the case of Rockwell testing, a steel ball or diamond cone is pressed onto the coil's surface with a predetermined force. The depth of penetration is then measured and compared to a standardized scale in order to determine the hardness value. Different scales are employed based on the size and type of indenter in use. On the other hand, Brinell testing involves using a spherical indenter made of tungsten carbide or hardened steel. This indenter is pressed onto the coil's surface with a known force, and the resulting indentation is measured and compared to a standardized table to determine the hardness value. Both methods provide a quantitative measure of the steel coil's hardness, which serves as an indicator of its ability to resist deformation, wear, and cracking. The hardness test results are subsequently utilized to ensure that the steel meets specific quality standards or customer requirements. It is important to note that the inspection process may involve sampling, where representative sections of the steel coil are tested, or it may involve testing the entire coil, depending on the specific inspection requirements. Additionally, accurate and reliable results necessitate proper calibration and maintenance of the hardness testers.

- Q: What are the advantages of using steel coils in various industries?

- There are several advantages of using steel coils in various industries. Firstly, steel coils offer exceptional strength and durability, making them suitable for heavy-duty applications. They can withstand extreme temperatures, pressure, and mechanical stress, ensuring reliable performance and longevity. Additionally, steel coils are highly resistant to corrosion, which is crucial in industries exposed to harsh environments or corrosive substances. Moreover, steel coils can be easily formed and shaped into different sizes and configurations, providing flexibility for various manufacturing processes. Lastly, steel is a sustainable material as it is recyclable, contributing to a greener and more environmentally friendly approach in industries.

Send your message to us

Z49 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords