Aggregate production line for railways and engineering

- Loading Port:

- Tianjin

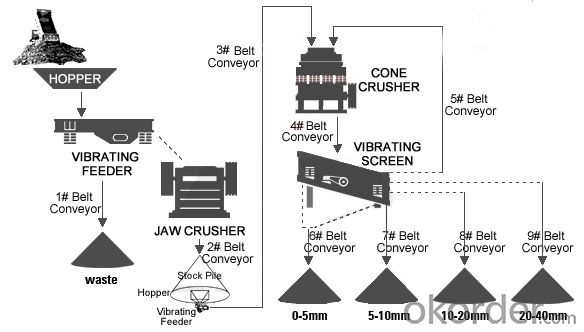

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aggregate production line for railways and engineering

Applications of Aggregate production line for railways and engineering:

1.Aggregates with grain size larger than 5mm are called coarse aggregates, and there are two kinds of gravel and pebble commonly used. Particle size grading: 5-10,10-20,20-31.5.

2.The aggregate with the grain size below 5mm is called fine aggregate. According to theproduction of sand is divided into natural sand and machine-made sand.

3.Aggregates as the main raw material in concrete because of its good hardness and stability of chemical properties ,It is play a role of the skeleton and support in the building. Widely used in housing, roads, roads, railways, engineering and other fields.

4.Aggregate production lines can be used for hard limestone, granite, basalt, river gravel, smelting slag and other materials, aggregate and artificial sand making operations,for Hydropower Station, building materials, highways, urban construction and other industries.

5.According to different process requirements, various types of equipment combined to meet customer's different process requirements.

Brief introduction of Aggregate production line for railways and engineering:

1.Aggregate production can be simply summarized as crushing and sorting, mainly from the conveyor, feeding, crushing, screening, sand and other aspects of aggregate production line introduced aggregate.

2.The choice of crushing equipment depends on the characteristics of ore raw materials, the local market demand for gravel products and production capacity of the production line.

3.Aggregate production line production process is as follows:

a.Large stone by the silo by the vibrating feeder evenly sent to the jaw crusher for coarse crushing, coarse crushed stone by the conveyor belt to the impact crusher for further crushing.

b.Crushed stone by the belt conveyor Sent to the vibrating screen for screening, screening out several different specifications of the stone, meet the requirements of the size of the stone conveyor belt conveyor, the finished product sent to finished heap.

c.Do not meet the requirements of stone by the conveyor belt back to the impact crusher to break again to form closed-loop multiple cycles.

d.Finished particle size can be combined in accordance with the needs of users and grading, to protect the environment, can be equipped with auxiliary dust removal equipment.

1.Vibrating feeding equipment

This type of vibrating feeder can continuously feed the material to the crusher continuously and make rough screening of the materials.

2.Crusher

1.According to the broken principle can be divided into two categories: extrusion crusher and impact crusher. Extrusion crusher (such as gyratory crusher, jaw crusher, cone crusher) is suitable for rock with high hardness and abrasive index (such as granite, quartz, diabase, basalt).

2.Impact crusher (such as the impact crusher, vertical shaft crusher, hammer impact crusher) to adapt to the hardness, abrasion index medium or low rock (such as limestone, dolomite, etc.).

1) jaw crusher

primary crushing of hard rocks and block materials

2) impact crusher

3) PYFB-1324 Composite cone crusher

PYFB-1324 compound cone crusher used in mining, cement, sand and gravel industry, for medium, fine broken, the pressure of 350 MPa in the following mine rocks, such as iron ore, non-ferrous metal ore, basalt, granite Limestone, sandstone, pebble stool.

3.Circular screen/vibrating screen---sieve the crushed stone into different sizes

4.Sand making equipment---Mainly vertical shaft sand or rod mill.

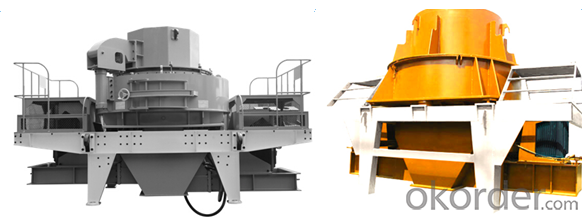

1) Vertical axis form of sand making machine

Sand making machine is widely used in a variety of fine ore broken. Sand making machine is widely used in medium and fine crushing fields of various hard and special hard materials such as ore, cement, refractory material, bauxite clinker, emery, glass raw material.

2) Rod mill

Rod mill is mainly used for preparation of sand. The material is raised to a certain height, falling state was dropped, the need for grinding of the material from the feeding Department of continuous into the cylinder, the grinding of the grinding medium is moving, and through the overflow and the power of continuous feeding the product out of the machine for the next processing step.

3) Screw classifier

Screw classifier used for the production of gravel in the process of particle size grading, and used in conjunction with mining machinery. Screw classifier Widely used in the ore dressing and ball mill with a closed loop, diversion of ore, or for gravimetric ore in the classification of ore and fine mud, and metal mineral processing process for particle size grading, and washing operations in the deslimation, dehydration and so on. The spiral classifier has the characteristics of simple structure, reliable operation and convenient operation. Also used for gravel operations in the deslimation or dehydration.

Advantages of Aggregate production line for railways and engineering:

a.The shape of the final product, with excellent quality.

b.Mud and powder content can be controlled.

c.This sand production line has the characteristics of high automation, low operating cost, high crushing rate, high productivity, and little pollution, etc. It is energy saving and is convenient to maintain.

d.Sand made by our sand production line is of equal size, good shape and reasonable distribution, complying with national building sand standard.

e.Due to reasonable matching of different levels of crushing machines and compact spatial arrangement, our crushing and screening plant has the features of small floor space, high economic efficiency. The crushed stones are of high quality, and the output rate of stone powder is low.

f. Meanwhile, our sand production line is equipped with electronic control system which ensures smooth discharging, reliable performance, high efficiency and energy conservation.

g.Our senior engineers design each production line according to different customers.

WINNER GROUP Sand Making Production Line Main Equipment Model/Specification/Quantity:

Maximum Feeding Size(mm) | Capacity(t/h) | Vibrating Feeder | Jaw Crusher | Fine Crushing Equipment (Impact Crusher) | Vibrating Screen | Conveyor Equipment(m) | Installed Power(KW) | |

340 | 30 | GZD2511(3kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1236(15kw) | 60-90(20kw) | 120 | |

340 | 50 | GZD3117(10kw) | PE400×600(30kw) | PF1007(45kw) | 3YZ1545(22kw) | 100-130(30kw) | 140 | |

420 | 80 | GZD3617(10kw) | PE500×750(55kw) | PF1010(75kw) | 3YZ1548(22kw) | 130-160(30kw) | 200 | |

480 | 100 | GZD4321(13kw) | PE600×900(75kw) | PF1210(130kw) | 3YZ1548(22kw) | 140-180(40kw) | 280 | |

560 | 150 | GZD4321(13kw) | PE750×1060(90kw) | PF1210(130kw) | 3YZ1845(22kw) | 200-240(50kw) | 300 | |

630 | 200 | GZD4321(13kw) | PE900×1060(110kw) | PFB1212(140kw) | 3YZ2050(30kw) | 200(40kw) | 350 | |

630 | 250 | GZD5027(17kw) | PE900×1060(110kw) | PFB1214(180kw) | 3YZ2050(30kw) | 200(40kw) | 400 | |

630 | 300 | GZD5027(17kw) | PE900×1200(110kw) | PFB1214(180kw) | 3YZ2160(30kw) | 250(50kw) | 450 | |

700 | 350 | GZD5027(17kw) | PE1000×1200(132kw) | PFB1315(250kw) | 3YZ2160(30kw) | 250(50kw) | 500 | |

700 | 450 | GZD6223(28kw) | PE1000×1200(132kw) | PFB1214/2(300kw) | 3YZ2145/2(60kw) | 350(60kw) | 600 |

If you want the stone production line, please tell me:

1) the raw stone material you want to crush

2) the raw stone material size

3) the final discharging size you request.

4) the capacity.

- Q: What's the application of ore shaker?

- [ore vibrating screen] advantages1, large processing capacity, high screening efficiency.2 、 the vibrator is lubricated by bearings, thin oil lubrication, and external block eccentric structure. The utility model has the advantages of large exciting force, small bearing load, low temperature, small noise, etc.. (bearing temperature rise less than 35 degrees).3, the vibrator whole assembly and disassembly, maintenance and replacement is convenient, greatly shorten the overhaul cycle. (it only takes 1~2 hours to replace the vibrator).4 、 the side plate of the screen machine adopts cold cold welding, no welding, high strength and long service life. The connection between the beam and the side plate is made of anti twist shear and high strength bolt. It is easy to replace without welding or cross beam.

- Q: Why does the vibration screen run dust appear, how should solve?

- On the other hand, not the device itself produces dust, but in a moment and feeding material caused by dust, if it is artificial feeding, to avoid dust, can in the above equipment plus closed silo and inlet sealing connection, the discharge port and the material receiving barrel sealing soft connection, the other can be added in dust collector the equipment to avoid dust.

- Q: What is the structure principle of sweet potato starch vibrating screen?

- The moving angle of the material on the screen surface can be changed by the phase angle of the upper section and the lower end, so that the material passes through the screen rapidly and achieves the purpose of sieving

- Q: What are the characteristics of the vibrating screen for latex paints?

- Vibration screening filter / power rotary vibration sieve is vibration motor, vibration motor shaft is provided with a hammer (uneven weight), through the vibration rotational movement of the motor under unbalanced heavy hammer into a horizontal, vertical, three-dimensional motion is inclined three sport, rotary vibration sieve using vibration motor three-dimensional movement, spring and the vibrating body through the rotary vibration sieve to transfer to a vibrating screen 3D motion. By changing the phase angle of the upper and lower heavy weights of the vibrating motor to realize the movement track of the material on the screen surface, the purpose of sieving, removing impurity and filtering is achieved.

- Q: Ask the TWB bearings? The crusher is used on vibrating screen

- Their products are not their own production, are OEM products, with the use of bad, small bearings can also be big not

- Q: What are the differences between MB and Ma bearings for vibration screens?

- Bearing MA room, the outer ring to guide the rolling mode, the specific design of the above bearing roller and inner ring is a gap.

- Q: How about paint vibrating screen?

- Each kind of machine has its own characteristic and the good work domain, the vibration sieve is precisely such.

- Q: How to change the screen of vibrating screen?

- With a soft hammer knock around uniform beam, then the copper nut. The change of mesh is completed. IfIn the process of changing the screen of the vibrating screen, the female net frame and the movable plate are taken off, and the moving hole must be noticed when it is loaded backThe plate must indeed be inserted into the flange of the underside of the grid.

- Q: What is the installation method of a vibrating screen?

- All parts of the screen machine should be firmly connected. All bolts should be tightened before starting.

- Q: What is the difference between an ultrasonic vibrating screen and an ordinary vibrating screen?

- The difference between screening materials: ordinary three yuan rotary vibrating screen can screen a variety of powder materials, and the sieve is divided into good effect. But in screening some, such as silicon carbide, Zong Gangyu, white corundum, cobalt powder, etc. in principle, it can be screened, but in the processing capacity and screening accuracy, it has not met the requirements. The ultrasonic vibration sieve exactly meets this requirement. Due to the installation of the ultrasonic transducer can be 220V or 110V, 50 Hz, 60 Hz power into high frequency 18 Hz, and then enter the ultrasonic transducer, the high-frequency electrical energy into mechanical vibration, the ultrafine powder material by ultrasonic acceleration strong, solving friction, produced in the process of screening drop, wedge such phenomena, improve screening accuracy and the processing quantity at the same time, since the net cleaning efficiency is significantly improved;

Send your message to us

Aggregate production line for railways and engineering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches