WPC Wood Plastic Composite Natural Colour Slip Resistance to Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

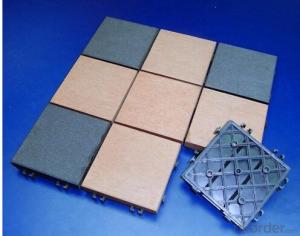

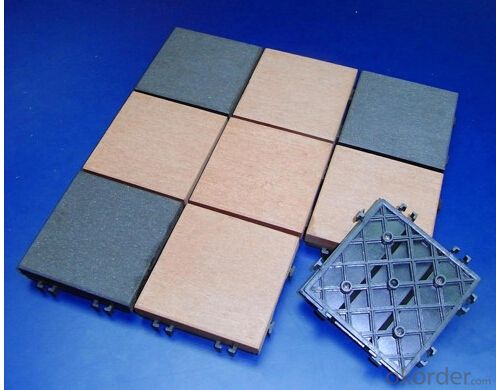

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q: Is Mirage flooring (engineered or lock), worth all that,and I and do you have it in your house-where?

- We installed a floating laminate floor years ago and love it. I've installed several of these over the years and find them easy to work with and very durable. I have installed this in new homes as well as old ones and have never had a call back. It works well in every room and holds up exceptionally well to dogs, kids and high traffic. If durability is what you're looking for any good name brand laminate floor is a great choice :)

- Q: 100 locusts know Hao version of Tongbao Kun ready to buy wood flooring, a friend said that the composite floor of the radiation formaldehyde or something. Answer, the composite wood floor with radiation and formaldehyde? How to identify and buy more environmentally friendly wood flooring more

- What decoration materials are radiation and formaldehyde, but with more problems with the fills, you can suddenly enriched, a few pots of Chlorophytum, live carbon, more than a period of time the wind can be a good floor to see the thickness, generally 1.23 About the knife can be used to see if there is no print, there is no need to select only the brand, things are just the same expensive advertising only.

- Q: I would like to ask which experts know the thickness of the composite floor to strengthen the specifications ah? Including the pavement from the original ground to the floor after the completion of how high ah? Thank you

- Strengthen the uniform specifications for the 1.2CM thick, length and width slightly different; composite uniform specifications 1.5CM Geng Terrier prostitutes mortar magic immortal lava thick; pavement when the ground will first shop a Cen about 0.1-0.2 thick moisture pad, and then Pavement

- Q: Composite floor with formaldehyde? Which brand of composite floor is not a full

- Any floor on the market have a whole but only how many of my home is the world floor of the floor quality is no problem A very much less

- Q: Will the composite floor out now 240MM wide board, and small board than that kind of good?

- Mainly to see your apartment to. Wide board is mainly a good scalability, suitable for large units, not material, loss of large. Small board for small units, the loss is not so big. Stability is better than big board. Composite floor material ridge ridge hoarding plateau lug chop is raft almost all, mainly to see what color they like. Suitable for their own decoration on the almost.

- Q: My house is decorated with a composite floor. Belong to the matt for the floating pile of spring nothing wrong Tong Feng Kun asked: whether the floor with essential oils or floor wax what the floor into the light? How can i be able to keep it long? Is the floor oil or floor wax harmful to the body? What is the average price? Thank you more

- To the composite floor waxing (or essential oil) there are two problems: 1, the floor does not absorb, each time playing the wax, accumulated to a certain thickness, you need to remove the wax. 2 to maintain a short time, every month a cycle, once the stop waxing, cracking, dirty phenomenon will produce, the effect is not as good as that of the ground, Never played. Specific fight and do not fight, you make your own ideas. My advice is: do not do maintenance to the composite floor. Floor oil and floor wax do not hurt the body. Price range: solid boxed ----- 10 yuan; spray pot ----- 20 yuan; liquid bottled ----- 30-40 yuan (including essential oils and wax); paste Natural ingredients ---- 100 yuan or so.

- Q: what is engineered flooring?

- building materials from okorder

- Q: Is it good for solid wood flooring or composite flooring?

- Each of the best of the first solid wood market is very small and the pavement maintenance are cumbersome and the price is so very little basic I think you are talking about the solid wood flooring and laminate flooring these two solid wood composite floor texture natural Feet comfortable and more environmentally friendly prices high Fu Fu Di Tai Gao Dian Dian Dian Dian Dian points to strengthen the composite price is low but strong and durable maintenance of the use of long life is the general public choice

- Q: My home on the 20th is just shop for the groom's 11.7 thick laminate flooring. The ground has a 60mm wide 300mm long 5-8mm drum kit. Because the master did not see the direct put the floor covered now walk in the above obvious feeling the middle of the two drums. Asked the shop that no problem flooring for several years will not be listed. After the resurfacing of the floor gap will be large, the floor may be more than the liver, I would like to ask the floor master. This problem with no need to open the floor to deal with the ground again shop. Reshaping what will be the problem, the floor seam will not increase the problem added: the floor did not glue. Press the edge of the plastic. He said the door to the special re-shop. But the floor can be more than the liver can be damaged (with door line) floor stitch may be larger than before. Are they right? There is such a big bag does not repeat the floor of the floor can do it, what the consequences of the floor more

- To see when the floor will hurt the lock, if the injury is not good

- Q: Because it is a newly renovated house has not moved Dinghu guilty cunning Chong twisted anchor into the floor flooding degree is relatively large, the water leaked 2 days to find the water seepage downstairs walls, paint are blasting Please come after the sale Treatment is to dig out the most serious part of the flooding, the rest do not deal with such water vapor their own volatile I would like to ask those who do not need to replace those soaked in the future will not mold mold, smell out of the problem added: Smell it? Plastic film must have been soaked, is not going to penetrate into the floor inside? More

- There is a certain risk. Put some fresh lime-like moisture-proof agent.

Send your message to us

WPC Wood Plastic Composite Natural Colour Slip Resistance to Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches