WPC Prefab Houses Wood Plastic Composite Deck board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of WPC Prefab Houses:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

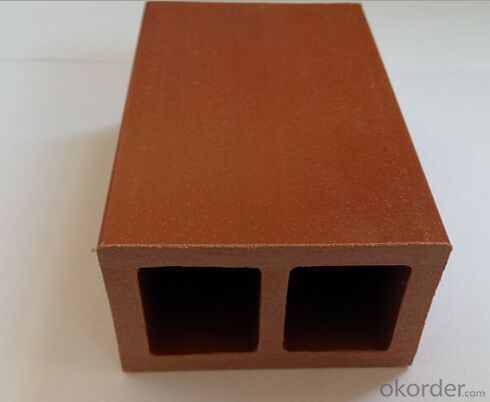

Composition of WPC Prefab Houses:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of WPC Prefab Houses:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of WPC Prefab Houses:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of WPC Prefab Houses:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

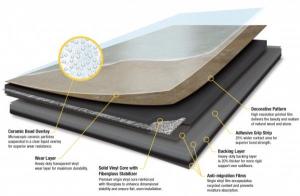

- Q: Board PVC plastic floor plastic toxic

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "Plastic floor" refers to the use of polyvinyl chloride materials production floor. PVC floor is widely used in all aspects of home and business because of its rich color and variety of colors.

- Q: What a pig with plastic floor to sell, how much money

- Advantages of polypropylene K8303:Good mechanical properties, high heat resistance, long life 5-8 years, chemical stability.The surface smooth high strength, good toughness, corrosion resistant parts of piglets in farrowing crate deformation, bearing capacityThe utility model has the advantages of strong force, long service life, no fear of flame, and the use of a flame sterilizer.

- Q: Today, just to shop on the EVA pad, the smell is very heavy to check it? What harm to the body

- Do not ignore the air circulation, ventilation for at least 4 hours a day, so that it can effectively eliminate harmful gases, is an effective way to prevent bacterial reproduction and increase oxygen. Floor should try not to composite floors, pure wood floors and wood floors best

- Q: What is the difference between plastic floor composite floor

- PVC floors and wood floors: wood floors can be broadly divided into three categories: solid wood flooring, solid wood flooring and laminate flooring. The wood floor is natural materials, synthetic materials have irreplaceable advantages, non-toxic and tasteless, comfortable, warm in winter and cool in summer

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- The shortcomings of the plastic floor: the laying of the floor construction requirements will be higher, to consider the floor, environment and other factors, some of the higher technical content

- Q: How much is a square floor of plastic floor?

- Durability: the product of raw materials for polypropylene (PP) for high strength materials, added with anti ultraviolet radiation, anti oxidant, cold resistant materials such as modified polypropylene, the advantages of the products with pressure, impact resistance, high temperature, long service life etc.. High weather resistance, high temperature, humidity, rain is not afraid of the sun, never warping deformation beneath the bitter snows. There is no climate zone restrictions, no water after the site

- Q: Warm the house, with plastic floor?

- Of course, there is one thing to tell you is that if you choose this floor, we must find authentic professional construction ability to ensure that the service agent to buy. Hair with the ground need to self leveling, the entire construction process should be very professional and very formal, to fully level, otherwise ugly. Now my floor has been used for two years, has not found quality problems. But compared to the advantages and disadvantages of other types of floor is: 1, no stone floor or cold feeling, 2 color, flower type, easy to clean wear many 3 disadvantages: 1, many people think that the lack of a sense of high-end 2, encountered organic solvent pollution is very difficult to clean

- Q: PVC plastic flooring should be how to pave the road, want to shop this floor, but do not know PVC plastic floor price per square meter of stone? Tell me what the trouble!

- Due to the thickness of the PVC plastic floor is only about 3mm without self bearing capacity, so the ground floor of the high requirements. The technical specifications and performance of this product and the basis of the construction of this product on the ground floor, and the development of standards for the detection of regulations. , 1 humidity: floor based moisture content should be less than 5%, keep the surface dry before construction. 2, surface hardness: 3, fast cutting surface roughness without a trace file or groove surface with a sharp chisel: 2 m straightedge inspection, voids should be less than 2mm. 4 crack: the ground crack width is less than 1.5mm. 5, surface density: the surface must not be too rough, not too many pores, to clean the floor. 6, surface cleanliness: oil, wax, paint, pigment and other residual material must be removed.

- Q: What is the role of badminton PVC plastic floor

- The glass fiber reinforced layer plays the role of stabilizing the size of the site and prolonging the service life, which makes the floor never shrink, the performance is more stable, and the athletes can play a better level.

- Q: Household PVC anti-static plastic floor

- This place is very heavy formaldehyde, it is recommended that the use of environmentally friendly materials for indoor decoration

Send your message to us

WPC Prefab Houses Wood Plastic Composite Deck board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords