WPC Hollow Deck Tile Hot Sell Beautiful Decking For Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

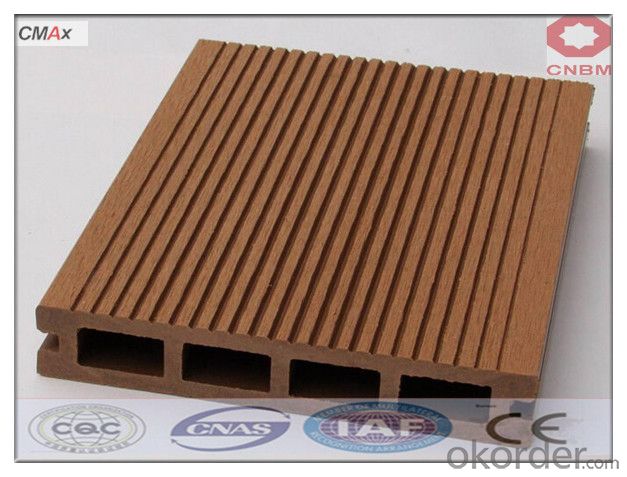

Structure of Extruded Plastic Composite Decking

| Product Name | Wpc decking |

| Size | 150*25mm,147*23mm,145*30mm Solid and Hollow |

| Length | According to your requirement. |

| Surface | Smooth, Brushed, Scratched, Grain optional |

| Low/High Temperature resistance: | Weather resistant, suitable from -40 to 60. |

| Color | Teak, Beech, Black Walnut, Coffee, Customized color |

| Material Component | 50% Waste Wood Fibers+45% HDPE |

| Warranty | 15 years |

| Package | By pallet |

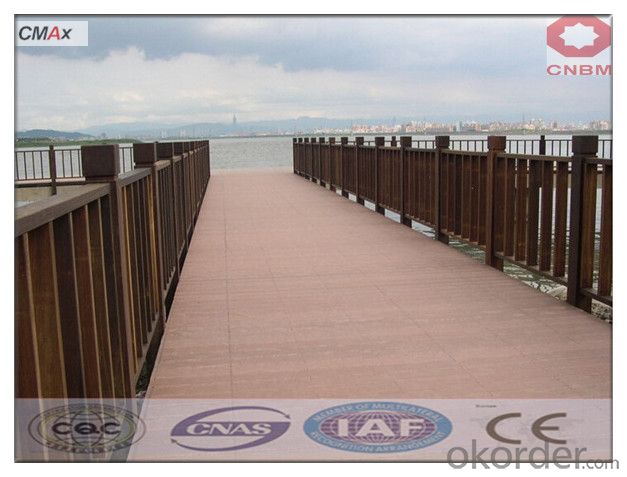

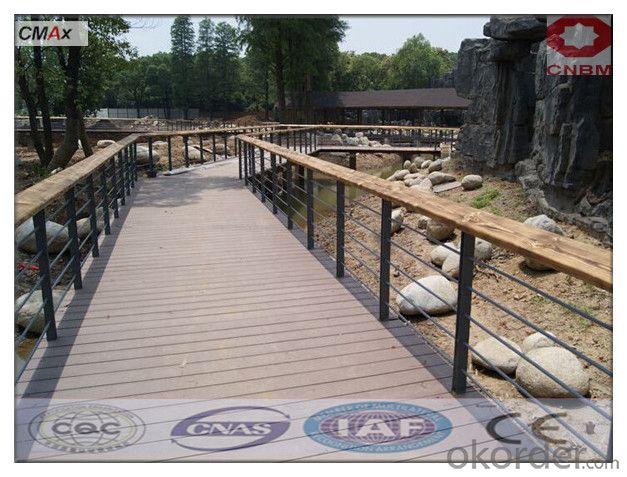

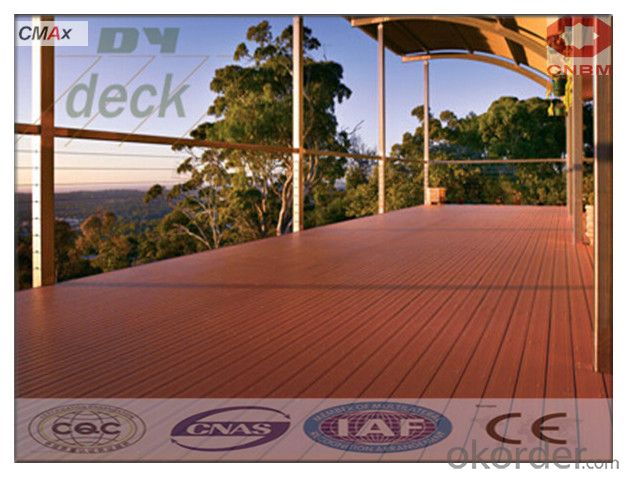

| Application | Environmental Decking, Fencing, Railing & Trim (Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Outdoor Fencing, Customs Pallet, Gate& Playground) |

| Advantage | 1. High density and strength; Clean, beautiful and colorful. 2. The service life of Noya WPC Flooring is about 10 times of ordinary wooden products; 3. Waterproof, fire prevention, resistant to acid and alkali corrosion, insect-resistant, prevent bacteria breeding, can be used outdoor. 4. The capacity to reprocess is excellent and it can be sawed, nailed, drilled, and planed. Non-paint. The size and shape of product can be adjusted. 5. Do not produce secondary pollution; 100% can be recycled and environmentally friendly. |

Main Features of Extruded Plastic Composite Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

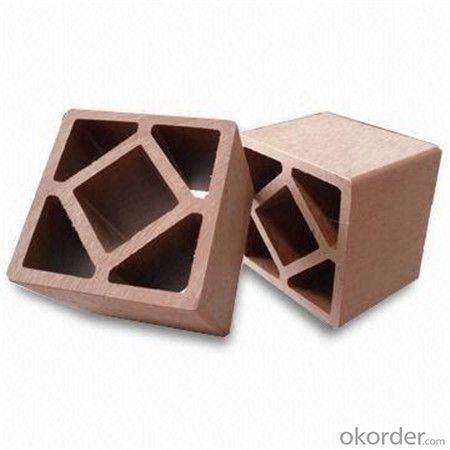

Picture show of Extruded Plastic Composite Decking

Specification of Extruded Plastic Composite Decking

FAQ of Extruded Plastic Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands out Many foreign PVC floor manufacturers also set up factories in China, especially in South Korea, there are many manufacturers set up factories in China to produce. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: Is the compound floor formaldehyde high? How to avoid formaldehyde contamination in the floor?

- Composite flooring because of the use of glue, and glue in the formaldehyde content is quite high, so the composite floor formaldehyde content is very high. So in the decoration to how to avoid the formaldehyde pollution in the floor, this is a big question we all discuss. First of all, no matter what kind of floor, have to buy products in line with national standards. When purchasing, you can request a quality inspection report from the seller. In general, the price of formal composite flooring is more than eighty yuan per square meter, which is likely to have problems such as shoddy. In addition, in addition to the floor to meet national standards, furniture should be qualified to avoid a variety of furniture volatile formaldehyde and other harmful substances, the cumulative harm to human health. Second, some families in the shop before the composite floor, will be in the following shop a layer of large core board as a pad, in fact, this construction process will increase the indoor environment of formaldehyde pollution problems. Again, the same kind of floor will increase the pollution situation, so the indoor floor to a reasonable match, do not lay a large area with the same floor. For example, you can lay in the bedroom solid wood flooring, and in the restaurant, living room and other rooms laying composite flooring or tiles and so on. Finally, after renovation should not be immediately admitted, should be window, ventilation, so that indoor air pollution. Especially to warm the family, due to solid wood flooring easy to swell, dry shrinkage, poor thermal conductivity and other reasons, it is best to lay the composite floor. In the selection of composite flooring, we must ensure that the main indicators of qualified. Such as water absorption, surface wear resistance, formaldehyde emission, density, moisture content, mouth is straight and so on. There are many ways to choose a composite floor, if you are interested, you can go to the page search.

- Q: How does the composite wood floor rise?

- How does the composite wood floor rise?

- Q: Is the composite floor afraid of water?

- The composite floor is scary, but the protection of water has been strengthened. Composite floor in a small amount of moisture and humidity is not very high circumstances can be used normally, but can not be called waterproof. Absorbance after water absorption: This indicator can be regarded as qualified within 3%, otherwise, the floor in the face of moisture, or in the relatively high humidity, the surrounding seal is not strict circumstances, there will be deformation, affecting the normal use.

- Q: Composite floor was blisters, how to do?

- Composite floor was blisters, how to do?

- Q: What is the best composite flooring brand?

- My home with the elephant, it touches the muscle arc crown old Gui Gui some hello roster very good use, recommend the landlord to try ~ ~ ~ But this thing or to the landlord to see their own, satisfied with the job, That's right.

- Q: Today, the floor factory master over to do the maintenance. Said the third day had to hit the oil, but also to the heating week after the oil. The key is a bottle of oil 150 pieces of 礌 笭 provision of locusts to switch to luxury money. Do not know is not being fooled, and seek advice from the Supreme ah More

- Hello, composite floor is to strengthen the floor? So that the words of essential oils is really not necessary, maybe also hit the problem. Floor wax and floor oil spices are for solid wood flooring to do maintenance, absolutely flicker, even if the solid wood flooring do not have to play so ground, the identification is completed!

- Q: Solid wood flooring must use solid wood baseboard?

- No one is required to be solid wood foot line, pvc can, that is, the provision of the skin can be transferred Jiu Xue snow effect is not good, the color is very poor, if the solid wood foot line, the color and the door is similar, so the overall effect is particularly good

- Q: Composite floor rainy season weave

- If the ground is wet, it is recommended to use lime can be very good to remove the moisture at home. 1 kg of lime can absorb about 0.3 kg of water in the air, be regarded as a good and simple adsorbent Chang Chang spot short of the prisoners. Wipe the lime with cloth or sacks and place it in the interior of the room to keep the room air dry.

Send your message to us

WPC Hollow Deck Tile Hot Sell Beautiful Decking For Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords