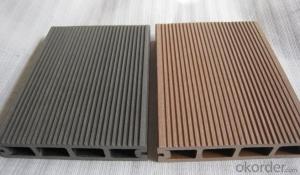

WPC decking/Hot sale WPC decking , WPC eco decking outdoor flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Solid wood composite floor moisture it?

- As long as the wood are not moisture-proof or short-term spill can not sprinkle for a long time do not clear the leak into the gap in the consequences that can be small can form a big hidden deformation of the wood is also the same business that moisture Are JB nonsense what the closure of the wax tube can not use the focus or their own maintenance of the other are nothing

- Q: In the old composite wood flooring and then add a layer of elephant composite wood flooring is possible, will not exceed the formaldehyde content

- The key to see you under the skin and the original between the floor of the gap can be allowed to cover a layer of composite floor volume. If the gap is not enough, it is necessary to break the door to shorten the door. Other no hindrance

- Q: It is good or seamless for the elephant floor

- There are two kinds of composite floor chamfering plate and molding plate. There are seam for the chamfering plate, seamless for the molded plate: ridicule cans of the immortal immortal Gui Jing pupil careful observation of the chamfering board around the paint for the edge, no wear-resistant layer, and can not be strict fit, A gap will seepage into the seepage of water, not take care. At the same time the paint side will be 1-2 years off, the substrate exposed to the outside, the water will penetrate into the substrate greatly affect the life of the floor. And the pressure plate wear layer is extended to the edge of the surface is a whole; combined with the assembly after the tight seam, just to make up for the lack of chamfer board. Another key can not be ignored is the lock, chamfering board is often flat buckle, in the process of flat buckle easy to fall off; and the new arc intelligent deduction bite force to avoid the use of the process of the above problems. Choose the floor

- Q: How to identify composite flooring quality (with photos)

- Shop a few, carefully listen to Purchasing Guide to explain, you naturally know

- Q: How about Sheng Chi composite floor

- Ah Yibai points of the floor is good or the World Expo Meteorological Museum designated brand my shop is Yibai points floor. Wool out of the body, no need to pursue the brand, I think are the same plate

- Q: Nature composite floor quality how?

- Quality does not know, it should be the main solid wood, solid wood composite is relatively small, and one of the samples on the pad putty, then the market is the quality of the natural staff too bad, do not know how the Red Star actually, Service better, the latter part of the problem is also better resolved

- Q: Composite flooring installation requires tools,

- Wooden floor installation requires the following tools: Power tools: hammer, pistol drill, marble sawing machine, curve saws, steam pump, steam gun, electric planer, mill, belt sander. Hand tools: hand saws, knife saws, fountains, steel tape, angle ruler, pencil, pull rope, hammer, ax, rubber hammer, punch, scraper, screwdriver, pliers, flat chisel, planing, Special tools: move the hook, tighten the hook. Wood flooring installation process should pay attention to: 1, wood flooring can not buy that shop, should be opened in the new home after a period of time and then shop, so that the wooden floor to adapt to the new environment. 2, do not think that the wood floor can not contain water, in fact, left the water, the wood floor becomes very hard, at the foot of the feeling is not the same, so to keep the wood floor water content of about 14%, of course, this is a professional tool inspection of. 3, wood grille and the ground between the grass-roots should retain a certain gap (primary school textbooks to teach us, to know how to stay a seam), to ensure that the entire ground dragon air patency, do not use cement mortar plug to fix the wood grid In order to use the mattress method, the wooden grille shall be firmly fixed to the ground with nails. 4, shop wood flooring should be cleaned before the wooden grille, sprinkle with moisture-proof powder and pest control powder. This is to prevent insects from eroding the wood flooring material and destroying the structure of the wood floor. 5, nail wood floor nails must use twist nails, first in the mouth of the mouth oblique drilling (holes should be perpendicular to the length of the floor), and then into the wooden grille, or the use of the process is likely to cause loose wood flooring. 6, after the laying of wood flooring to use cardboard, old sheets or old mats and other cover protection. The purpose of this is to protect the original installation of the wood floor structure, firm its structure.

- Q: Home immediately to decoration, and now has been considering the use of solid wood flooring or laminate flooring good? Look at the wood composite floor, wood flooring is not a wooden board, do not know what kind of money is more affordable, but also moisture, long service life? It is a fog! Please give me advice under more

- Solid wood flooring structure is three or more than three layers of thin wood bonded together, strengthen the floor is made of wood and materials from the beating press, from the price point of view, strengthen the floor than the solid wood flooring cheaper. From the environmental point of view, the floor in the bonding process, need to use glue. The quality of the glue used by the manufacturers is not the same. Adhesive contains formaldehyde, strengthen the use of plastic glue on the floor, if the high content of formaldehyde in the plastic, does not meet the national evaluation criteria, it is bound to the high content of formaldehyde, the skeleton of the frozen meat, , Affecting family life health. And solid wood composite floor with less glue, so, relatively speaking, low formaldehyde content, the quality is more environmentally friendly. If you choose the international environmental quality of the floor, then the problem of formaldehyde do not have to worry too much, strengthen the floor is also a good choice, after all, to strengthen the floor easier to manage, and cheap, suitable for mass consumption. From the comfort point of view, solid wood flooring foot feel due to strengthen the floor.

- Q: Solid wood composite flooring product quality

- Solid wood composite flooring product quality

- Q: My home on the 20th is just shop for the groom's 11.7 thick laminate flooring. The ground has a 60mm wide 300mm long 5-8mm drum kit. Because the master did not see the direct put the floor covered now walk in the above obvious feeling the middle of the two drums. Asked the shop that no problem flooring for several years will not be listed. After the resurfacing of the floor gap will be large, the floor may be more than the liver, I would like to ask the floor master. This problem with no need to open the floor to deal with the ground again shop. Reshaping what will be the problem, the floor seam will not increase the problem added: the floor did not glue. Press the edge of the plastic. He said the door to the special re-shop. But the floor can be more than the liver can be damaged (with door line) floor stitch may be larger than before. Are they right? There is such a big bag does not repeat the floor of the floor can do it, what the consequences of the floor more

- And the thickness of the relationship must not be re-shop just after the drum package will be more and more strengthened after the strong but the installation must be meticulous now, whether it is not locked floor businessmen do not glue to the customer environmental protection and product quality Impression can be a problem but not a small thing I suggest you hurry to reload the drums to get the local repair on the line is not trouble

Send your message to us

WPC decking/Hot sale WPC decking , WPC eco decking outdoor flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords