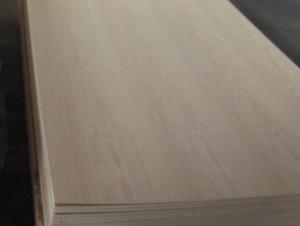

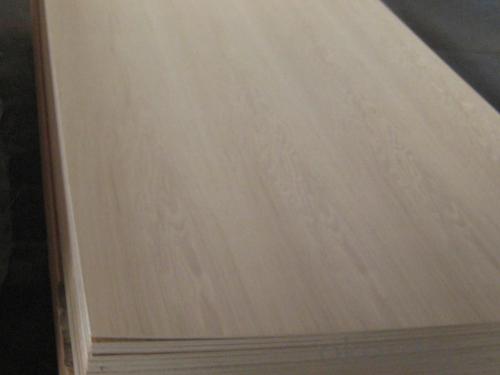

3/8 Inch Wood Veneer Sheet, 18mm Poplar Core Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM |

| Model Number: | GB18580 | Usage: | Outdoor | Grade: | First-Class |

| Main Material: | Poplar | Formaldehyde Emission Standards: | E1 | Plywood Type: | as request |

SPECIFICATION

Name | commercial plywood for export | |

Size | 1220x2440mm(4'*8'),1250x2500mm(4.1'*8.2'),1830x915(3'*6')/1820x910mm or as Agreed | |

Thickness | 2.5mm—30mm | |

Thickness Tolerance | ≤6mm | ±0.2mm to ±0.3mm, |

6mm—30mm | ±0.4mm to ±0.5mm | |

Core | Eucalyptus | |

Face/Back |

Okoume,bintangor,birch,pine,agathis,pencil-cedar,bleached poplar,black,brown

| |

Glue | MR, WBP, Melamine. (E0, E1, E2) | |

Grade | BB/BB,BB/CC ,CC/CC or As Agreed | |

Moisture | 8%-16% | |

Usage | Decoration, Furniture, package etc. | |

Package | Inter packing: 0.20mm plastic bag. | |

Outer packing: pallets are covered with plywood or carton and then steel for strength. | ||

Conveyance | 20’GP | 8pallets/ 22m³ |

40’GP | 16pallets/ 42m³ | |

40’HQ | 18pallets/53m³ | |

Delivery time | Within 35 days on receipt of deposit or original L/C. | |

Price terms | FOB, CFR, CIF | |

FEATURE

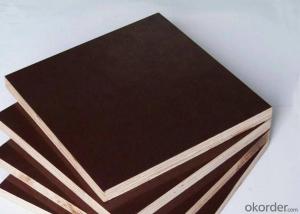

1. Transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2. After installation of concrete, the surface looks like a mirror. (the cement does not stick.)

3. You are able to use film faced plywood until the plywood itself is damaged. (Strong with nailing and knifing)

4. Environmentally friendly. (Even after incineration, there is no hazardous substance.)

5. It can be used for a long time, and for the initial price paid for the material, you will feel its worth

- Q: The difference between the multilayer board and the plywood is as follows

- Also available for aircraft, ships, trains, cars, construction and packaging board and other materials.

- Q: What is the composition of the plywood?

- Glue plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression.

- Q: Commonly used plywood, pallets and so on

- straw and other things containing wood fiber, very cheap, so the cost of producing MDF is very low so the market price is cheaper than the solid wood.

- Q: What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q: A brief introduction to plywood

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: The Decorative veneer veneer plywood grade classification

- China veneer veneer veneer plywood standard veneer veneer plywood is divided into excellent products, first-class goods and qualified three grades

- Q: What are the defects in plywood material?

- holes In the process of shipment, holes are caused by hooks and tools for workers' picking.

- Q: What are the defects of the plywood?

- The intergrown knots are formed by the tree's live technique. Knots and the surrounding wood close together or with the surrounding wood part of the length of its cross-section than the length of 3/4, hard texture, normal structure

- Q: What are the advantages and disadvantages of plywood?

- and then made of adhesive glue from the three or more layers of plate-like material

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

Send your message to us

3/8 Inch Wood Veneer Sheet, 18mm Poplar Core Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords