Wood Plastic Composite Flooring Use for Outdoor Decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Flooring:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

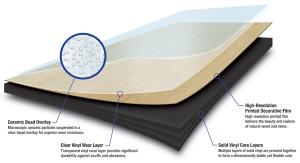

Composition of Wood Plastic Composite Flooring

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of Wood Plastic Composite Flooring

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of Wood Plastic Composite Flooring:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of Wood Plastic Composite Flooring:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: Can the bathroom PVC plastic floor?

- The bathroom (bathroom) is not only a toilet, but the toilet, toilet, bath collectively. According to the layout of the bathroom can be divided into independent, dual and eclectic type three.

- Q: PVC plastic floor construction costs a square meter

- Our office is a very good use of Gerflor 170 a square meter construction costs

- Q: PVC plastic floor maintenance and maintenance, daily cleaning what is a good way?

- Wet mop. (with floor cleaning agent 1: 20 diluted with water, with a half wet mop mopping the floor.) if necessary, can also be used to clean the floor with wash & Shine low speed cleaning.

- Q: That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- First, the purchase is the key to how to choose some of the moisture resistance of the ceramic tile, is the key to continue to enjoy the dry life in winter, there are six criteria for everyone to choose. The first: low water absorption rate of this tile usually have good moisture resistance, when buying, we can crack is tile surface observation, other glaze layer thick ceramic tile will also increase the moisture resistance of ceramic tile to a certain extent. Therefore, the user in the selection of ceramic tiles to watch the special table when the water content, water content less, good moisture-proof tiles, of course, the price is also high

- Q: Can the plastic stair step of the cement in the home spread the plastic floor

- Need to do cement self leveling. If the surface is flat, can be installed directly

- Q: PVC plastic floor defects

- 1, the construction of the basic requirements of high2, afraid of cigarette burns3, afraid of sharp scratches

- Q: Plastic floor shop no artificial labor costs per square meter

- Plastic floor price gap is small, good quality plastic floor price: 45 yuan -80 yuan between. Plus plastic floor accessories and some labor costs in the price: 100 yuan -120 yuan between. Construction of 10 square meters per square meter, accessories accessories of about 40 yuan per square meter, the local price is not the same

- Q: Plastic foam flooring is not a large mosaic floor.

- When the children grow up, the floor needs to be replaced. What is the relationship between the damage to the floor, and then you can re paint it. Tiling can also be placed on the floor, you can let the children split up, spell the demolition, not much impact on the floor.

- Q: What are the differences between plastic floor and floor tiles

- Floor leather is to roll PVC sheet flooring, the floor and the people said the floor is essentially different, the past is the floor leather leather surface decoration materials, only used for luggage, leather products and flooring, floor leather past poor wear resistance, scratch resistance, as well as a pungent odor, poor stability easily damaged. Now the PVC roll floor has the characteristics of wear resistance, dirt resistance, antibacterial, environmental protection, stability, safety, fire prevention, sound insulation, far better than the previous floor leather.

- Q: How much is a normal plastic floor

- The price is about 20 yuan a square meter, such as the sports floor is the main step, mainly to see what occasion you use a slightly different price, hoping to help you

Send your message to us

Wood Plastic Composite Flooring Use for Outdoor Decking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords