Wood Plastic Composite Flooring Use for Landscape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Flooring Use for Landscape

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

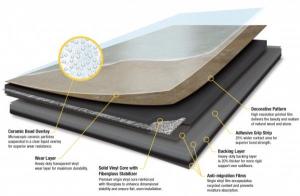

Composition of Wood Plastic Composite Flooring Use for Landscape

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of Wood Plastic Composite Flooring Use for Landscape

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of Wood Plastic Composite Flooring Use for Landscape

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of Wood Plastic Composite Flooring Use for Landscape

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: What is the plastic floor and what is the compound floor?

- The floor has a new material composition, water resistance, generally suitable for public use. Composite floor, broadly speaking, refers to the structure of several layers of the composite floor, such as: laminate flooring, multi-layer solid wood flooring, bamboo flooring, etc..

- Q: What a pig with plastic floor to sell, how much money

- Plastic drain board characteristics:Double strength, excellent toughness;Good heat preservation performance, smooth surface, do not hurt piglets;It is easy to leak, strong and durable, corrosion resistance, aging resistance;The utility model has the advantages of convenient use, quick installation, time saving and labor saving, and the utility model has the advantages that the bed surface is clean, the disease is reduced, and the growth of the piglets is faster

- Q: Plastic floor shop no artificial labor costs per square meter

- Plastic floor price gap is small, good quality plastic floor price: 45 yuan -80 yuan between. Plus plastic floor accessories and some labor costs in the price: 100 yuan -120 yuan between. Construction of 10 square meters per square meter, accessories accessories of about 40 yuan per square meter, the local price is not the same

- Q: What is the difference between hard and soft plastic floor construction

- Generally speaking: the difference between hard PVC and soft PVC is that the hard PVC is very hard, and steel, wood almost, and soft PVC is very soft, and rubber hose. Applications are very broad, the key is to look at the environment and occasions you use.

- Q: Spread a layer of plastic cloth under the wooden floor

- To prevent dust on anti words as long as the ground brush a layer of latex paint can paint decoration paint can save the paint that wouldn't have covered the ground very neat brush can plastic once the moisture is easy to produce water on the floor under the mildew bacteria The loss outweighs the gain.

- Q: Plastic floor coil and sheet are what size

- The definition of plastic (the United States plastics industry association): mainly composed of carbon, hydrogen and oxygen, nitrogen and other organic or inorganic elements, the finished product is solid, in the manufacturing process is molten liquid, so can take heating to melting, the pressure makes the flow, cooling the solids, and the formation of a variety of shapes, this huge material group called plastic be the most changeful.

- Q: What glue paste on plastic floor

- Generally, the use of water-based glue, look at the place of use, resin glue can also, or two-component glue, water-based glue to add other materials

- Q: What are the main construction process of laying plastic floor

- (3) plastic floor:Cutting, processing, scraping and wire grass, paste, rolling, curing.

- Q: How to clean plastic floor

- 2, while the start of the water suction machine, while scrubbing the suction in addition to sewage, washing machine can not be washed to the plastic floor can be used to mop the dry cleaning detergent.

- Q: Shop: composite floor below the moisture with plastic mold moisture do?

- Composite floor installation suspension installation: the first is the glue. The quality of the glue determines the quality of the floor, but also directly related to the length of service life.

Send your message to us

Wood Plastic Composite Flooring Use for Landscape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords