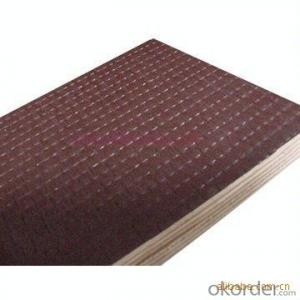

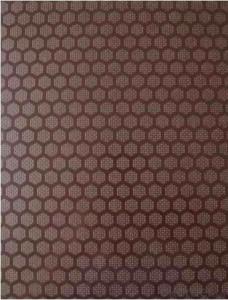

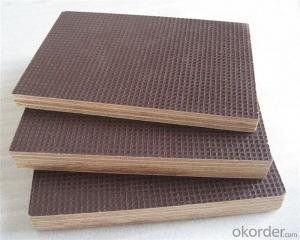

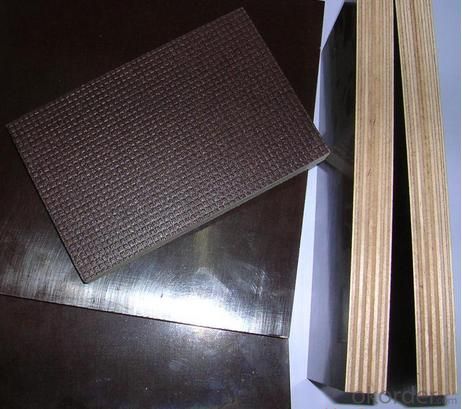

1/4 Plywood Home Depot Wiremesh Design Anti-Slippery Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

WireMesh Anti-Slippery Film Faced Plywood are widely used in construction repeatly and sometimes for stage boards..

Characters:

Anti-Slipping, Different styles/Designs, Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Detailed Specification:

Product name:Wire Mesh Anti-Slippery Film Faced Plywood

Size:1220x2440mm,1250x2500mm

Hot press: two times hot press

Thickness:9mm,12mm,15mm,18mm,20mm,21mm,25mm

Tolerance: +/-0.5mm

Core:Poplar,Eucalyptus,hardwood,combi

Film:brown with/without logo

Glue:MR,WBP(melamine),WBP(phenolic)

Grade:First class

Moisture:below 14%

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.How many times it can be used?

A1: It mainly depends on hotpress times, quality of raw materials and type of Glue. Normally, Melamine glue poplar core two times hot press film faced plywood can be used about 5-8times.

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Fibreboard: According to bulk density is divided into hard fiber board, semi-rigid fiberboard and soft fiber board 3 kinds. Hard fiber board is mainly used for the ceiling,

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- High-quality urea-formaldehyde glue / melamine glue / phenolic glue can reach E0 level, E1 level, that can be used directly for indoor

- Q: Multilayer board and plywood difference

- The multilayer board is usually arranged symmetrically on both sides of the center or core.

- Q: What are the processing defects of plywood?

- Patched Plywood Repaired plywood Defects Plywood that has been repaired with a filler or veneer patch.

- Q: What are the defects in plywood material?

- holes In the process of shipment, holes are caused by hooks and tools for workers' picking.

- Q: What is the density of plywood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: What are the defects of the plywood?

- partially intergrown knOts surrounded by the surrounding wood part of the length of its cross-section around the length of more than 1/4 to 3/4, texture Kuang hard.

- Q: Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

Send your message to us

1/4 Plywood Home Depot Wiremesh Design Anti-Slippery Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords