Wire Harness Tape Fabric Carrier Fleece Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wire Harness Tape Fabric Carrier Fleece Cloth

1. Structure of Wire Harness Tape Description

Wire Harness Tape is of fabric as the carrier, coating with synthetic rubber based, acrylic based adhesive. Wire Harness Tape: widely used for cable harnessing in the automotive industry.

2. Main Features of the Wire Harness Tape

Water resistant and moisture resistant

Good insulation

Flame retardant

Self extinguishing

Non-corrosive adhesive

3. Wire Harness Tape Images

4. Wire Harness Tape Specification

Item No. | Thickness (micron) | Adhesion to steel (N/cm) | Tensile Strength (N/cm) | Elogation at break (%) | Teperature Resistance (DC) | Flame Resistance (S) |

WH-10 | 0.25 | 1.2 | 75 | 15 | - | -40 - 105 |

WH-23 | 0.25 | 2.5 | 180 | 15 | 1000 | -40 - 150 |

WH-23A | 0.25 | 1.5 | 65 | 10 | - | -40 - 125 |

WH-25 | 1.2 | 2 | 270 | 50 | 5000 | -40 - 125 |

WH-31 | 0.3 | 2.5 | 20 | 10 | - | -40 - 105 |

WH-95 | 1.5 | 1.5 | 100 | 30 | - | -40 - 130 |

5. FAQ

Q1. What is our company?

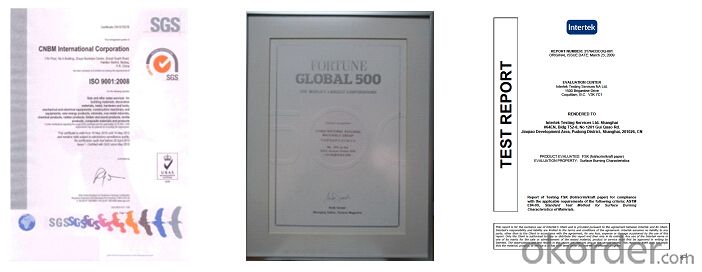

CNBM International Corporation is a state-owned company. As World Top 500 Company, we have clients from over 120 countries and overseas branches in 5 countries. We specialized in adhesive tape for over 20 years, with SGS and ISO9001 certified and Grade AA for Export.

Q2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: Can packaging tape be used for sealing metal boxes?

- Indeed, metal boxes can be sealed using packaging tape. Specifically engineered to create a secure and long-lasting seal on different surfaces, such as metal, packaging tape possesses a powerful adhesive that effectively adheres to metal, guaranteeing that the box stays sealed throughout storage or transportation. Nevertheless, it is crucial to select a packaging tape appropriate for demanding tasks, capable of enduring the weight and pressure that the metal box may experience. Furthermore, it is advised to cleanse the metal surface prior to applying the tape to ensure optimal adhesion.

- Q: Can packaging tape be used for sealing wooden crates?

- Sealing wooden crates can indeed be accomplished with packaging tape, which creates a sturdy and reliable bond. This ensures that the crate remains tightly sealed throughout transportation or storage. Packaging tape is specifically designed to adhere well to different surfaces, including wood, making it an excellent option for sealing wooden crates. Nevertheless, it's crucial to take into account the weight and dimensions of the crate before solely depending on packaging tape. In the case of heavier or larger crates, reinforcing the seal with supplementary methods like nails or screws may be necessary.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. It provides a secure and reliable seal, helping to protect the contents during transit or storage.

- Q: Is packaging tape resistant to tearing or ripping?

- Yes, packaging tape is typically resistant to tearing or ripping. It is designed to provide a strong and secure seal on packages, ensuring that they remain intact during transit or handling. Packaging tape is made from durable materials such as polypropylene or reinforced paper, which offer high tensile strength and tear resistance. Additionally, many packaging tapes have adhesive properties that further enhance their resistance to tearing or ripping. However, it is important to note that the strength and tear resistance of packaging tape may vary depending on the specific brand or type of tape used.

- Q: How do I prevent packaging tape from becoming too sticky?

- To prevent packaging tape from becoming too sticky, there are a few measures you can take: 1. Store tape in a cool and dry place: Heat and humidity can often cause the adhesive on packaging tape to become stickier. Ensure that you store the tape in a cool and dry environment to maintain its proper consistency. 2. Avoid contact with dust and debris: Dust and debris can stick to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and make sure the areas where you will apply the tape are clean and free from any loose particles. 3. Use a tape dispenser: A tape dispenser can help regulate the amount of tape you apply and prevent excessive stickiness. It allows for a more controlled application and ensures you don't use more tape than necessary. 4. Don't stretch the tape excessively: Stretching the tape too much while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it excessively, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you consistently face issues with sticky packaging tape, you can opt for low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these tips, you can maintain the desired level of stickiness on your packaging tape and make your packaging process more efficient.

- Q: Can packaging tape be used for sealing storage containers?

- Packaging tape is an ideal choice for sealing storage containers. Its design focuses on delivering a strong and secure seal for a variety of materials, including storage containers. The packaging and shipping industries frequently rely on it to seal boxes, cartons, and other containers. Thanks to its robust adhesive, packaging tape can withstand the challenges of storage and transportation, guaranteeing the safety and protection of container contents. Moreover, its application is effortless, and it offers a dependable seal that effectively keeps dust, dirt, and moisture from infiltrating the storage container. Hence, utilizing packaging tape for sealing storage containers proves to be a practical and efficient solution.

- Q: Is packaging tape easy to tear?

- Yes, packaging tape is designed to be easy to tear. It typically has a serrated edge or perforations that make it convenient to tear by hand without the need for any additional tools.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Yes, packaging tape can be used for sealing wooden crates or pallets. It provides a secure adhesion and helps to keep the contents of the crates or pallets protected during transportation or storage.

- Q: What are the benefits of using low-noise packaging tape?

- Low-noise packaging tape offers several advantages. Firstly, it is designed to minimize or eliminate the loud noise that traditional packaging tapes often produce when unwound or dispensed. This is especially beneficial in office or retail environments where a quiet and peaceful atmosphere is desired. By reducing noise levels, low-noise packaging tape creates a more comfortable and less disruptive work environment. Secondly, low-noise packaging tape is typically made from high-quality materials that provide superior strength and adhesion. As a result, it ensures a reliable and secure seal on packages, reducing the risk of damage or loss during transit. The strong adhesive properties of low-noise packaging tape ensure it remains in place even in challenging conditions, such as extreme temperatures or high humidity. Another advantage of low-noise packaging tape is its user-friendly nature. It is designed for easy dispensing from a tape dispenser, enabling quick and efficient application. This saves time and effort for users, particularly in high-volume packaging operations or busy shipping departments. The smooth and consistent unwinding of low-noise packaging tape further enhances its ease of use, preventing tangles or snags that can lead to frustration and wasted tape. Furthermore, low-noise packaging tape is often available in various sizes, widths, and colors, allowing for customization based on specific packaging needs. This versatility ensures it can be utilized for a wide range of applications, from sealing small envelopes or boxes to securing larger packages for shipping. The different color options also aid in organization and identification, making it easier to differentiate between different types of packages or mark fragile items. Overall, the benefits of low-noise packaging tape include noise reduction, reliable seals, ease of use, and customization options. By selecting low-noise packaging tape, businesses can enhance the overall packaging experience for both employees and customers, leading to increased productivity, customer satisfaction, and the protection of valuable goods.

Send your message to us

Wire Harness Tape Fabric Carrier Fleece Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords