Wholesale Steel Plastic Composite Pipe Fiberglass Pultrusion Corrosion Resistant FRP Rod Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Filament winding is a molding process. Fiber glass roving is pulled through a bath of catalyzed resin and impregnated. The resin impregnated roving is wound under tension on to a cylindrical. The composite material cures and the mandrel is removed. Filament winding is used to make high strength, hollow, and typically columnar composites, such as pipe, fitting and storage tanks.

FEATURES

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid.

SPECIFICATIONS

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

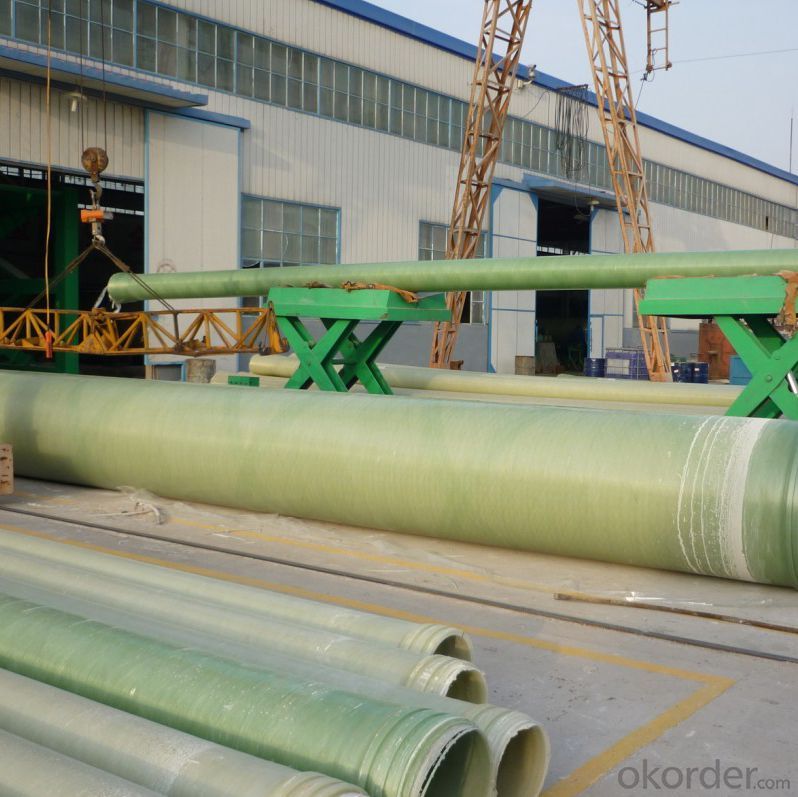

PICTURES

- Q: What are the differences between inorganic FRP pipes and plexiglass pipes, what are the advantages and disadvantages?

- Fiberglass pipeacid: organic resin and glass fiber cloth hand pasting a small proportion of strength and long life advantages

- Q: What qualifications do FRP pipes need to export to Australia?

- Need to comply with the local certification standards or international certification standards certification system

- Q: Glass tube has different diameters with different prices. Who can elaborate?

- If it is a sand lined pipe, the rigidity grade is 25005000750010000Prices are calculated according to these

- Q: What is the difference between glass tube, sand pipe and glass tube?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: How to install FRP pipe correctly

- Field bonding process is usually provided by glass fiber reinforced plastic manufacturers, if there is no way, I can provide some experience for reference, there is little information, experience only.

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- General glass fiber reinforced plastic, no corrosion protection.If buried with epoxy coal pitch can be, anti rust grade Sa2.5, six oil four cloth can.

- Q: Slurry circulation glass fiber reinforced plastic pipe

- Slurry circulation glass fiber reinforced plastic pipeline has good corrosion resistance. FRP pipes are resistant to acid, alkaline, and non fluid erosion. In general, the service life of the steel pipe is 15 years, the cast iron pipe is 5 - 10 years, and the glass tube can be used for 50 years.

- Q: Which is better, pultruded FRP square pipe with PVC?

- When abrasive materials are transported in the wear-resistant pipes (such as ash, coal dust, ore fines, etc.), there is a problem of rapid wear and tear of the wear-resistant pipes, especially the rapid wear of the bent pipe.

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- The glass fiber reinforced concrete grille is made of three kinds of polypropylene, polyvinyl chloride and ethylene propylene copolymer. The FRP grille is only half the size of the glass, saving transportation, unloading, mounting, and supporting the cost of the frame.

Send your message to us

Wholesale Steel Plastic Composite Pipe Fiberglass Pultrusion Corrosion Resistant FRP Rod Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords