Cpvc Composite Fiberglass Hollow Rod FRP Pultrusion Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP Fitting, a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact

molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed resin, and sprayed onto the mould surface.

FEATURES

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

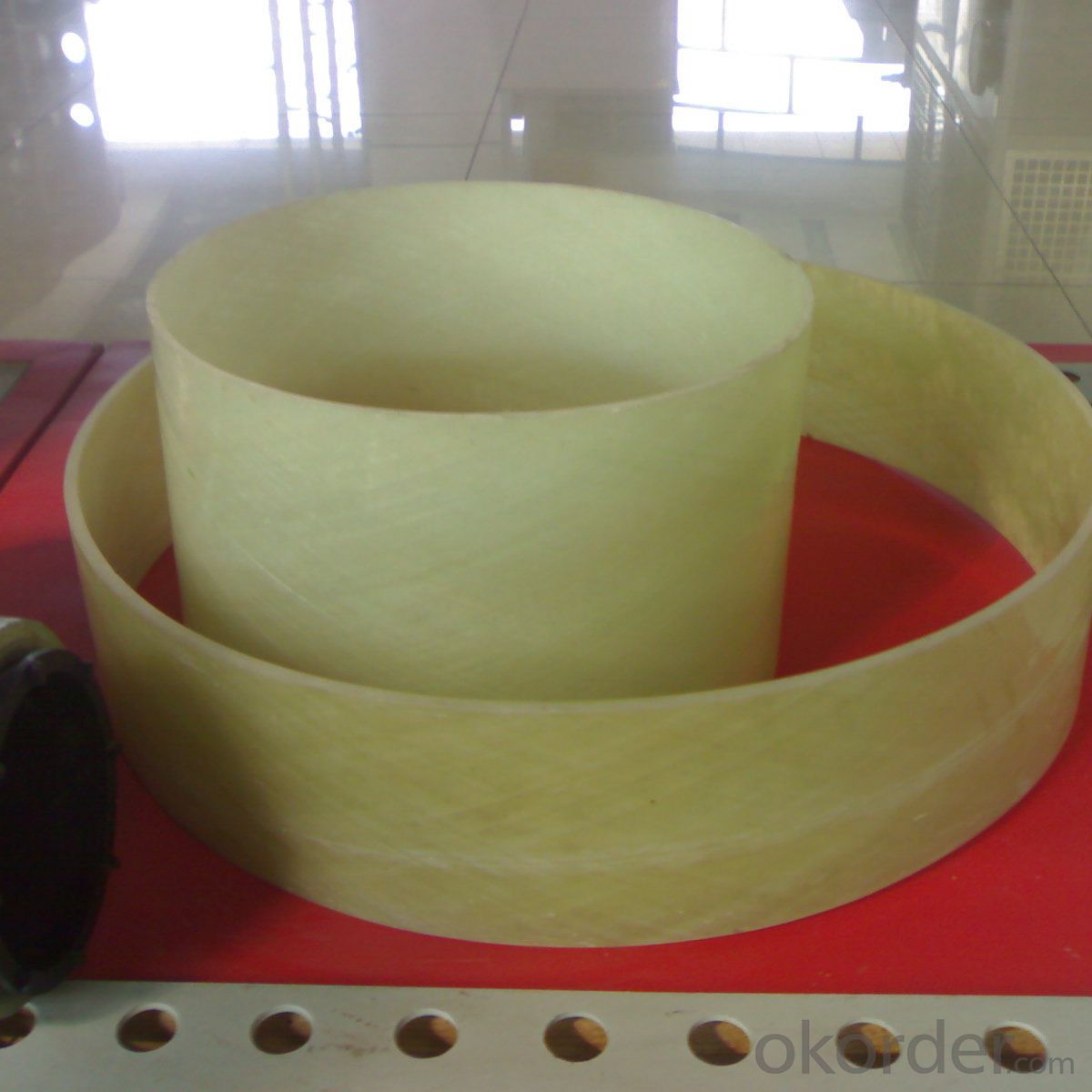

PICTURES

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- This depends on the size of the pipe diameter, the greater the diameter, the thicker the wall.

- Q: Is it useful to make gas pipelines with glass steel pipes? Or the idea that the technology is mature?

- Now the general use of steel pipe with PE pipe is very good, I don't FRP clearance, but there may be enamel can also withstand the pressure vessel, 3 class.

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- In order to improve the quality of glass.Advanced technology may be used.The ratio seems to be 1 to 0.001. Pretty much within this range.

- Q: Are FRP pipes still developing?

- Glass steel complex (or perhaps not, but not absolutely continuous production mishap) manufacturing process, and China quality is not strictly controlled, low cost of pipeline as well as PVC and other engineering plastics, the high demand of the field of steel as reliable, is now used for chemical terminal treatment, city drainage etc..

- Q: What is the difference between glass tube, sand pipe and glass tube?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- The service will be restored in 24 hours, and I hope this will help you! Can private letter to contact is not clear!

- Q: What is the standard of flange coefficient for FRP ducts?

- Can be explained in this way, the flange width is generally 50, on both sides that is 100, flange thickness is calculated as two times the thickness of the pipe, or 200. The duct length is 2000 knots, and 200 is 2000 of the 10%

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Use a high strength resin type;

- Q: What is the thickness of all types of FRP pipes?

- The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

- Q: What are FRP pipes used for making? What raw materials?

- The glass tube with its unique strong corrosion resistance, smooth surface materials, low energy consumption and long service life (50 years), convenient transportation and installation, maintenance and many other advantages of low cost and low cost in electric power, petroleum, chemical industry, papermaking, city water supply and drainage, sewage treatment plant, seawater desalination, gas transportation other industries have been widely applied.

Send your message to us

Cpvc Composite Fiberglass Hollow Rod FRP Pultrusion Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords