Whole Aluminum Formwork with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

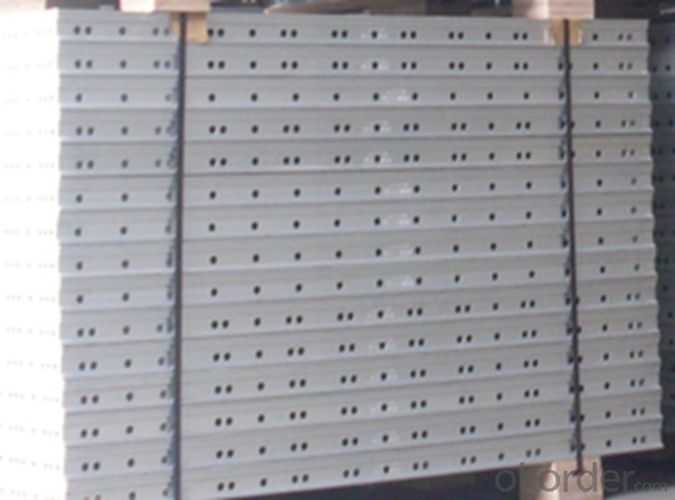

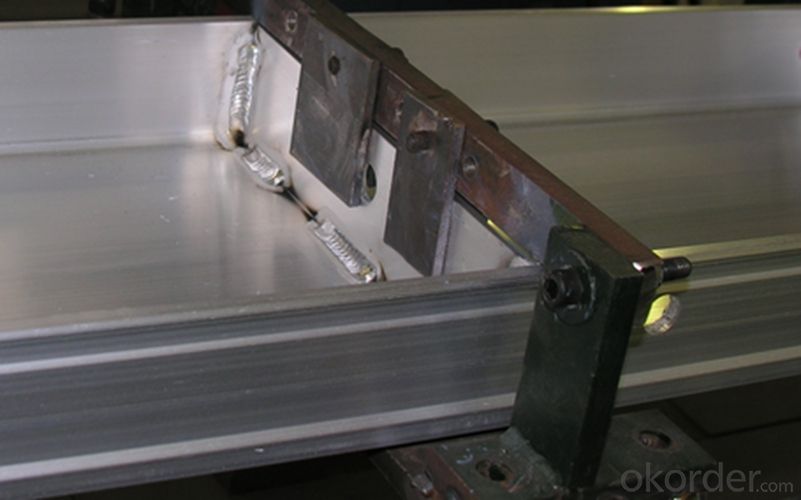

3. Whole Aluminum Formwork Images

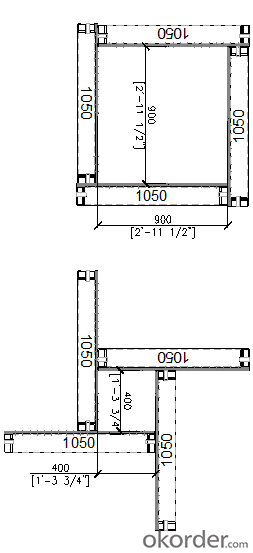

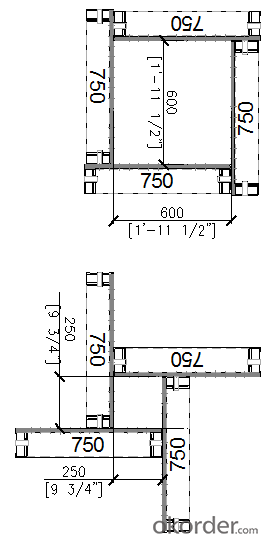

4.Whole Aluminum Formwork Specifications

1) MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2) DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3) StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4) StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Please feel free to customize.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale services?

Response will be carried out in 24hours after receiving any complain or request.

- Q: Changsha Sanlian Building Machinery Fittings Factory

- In addition, you can check the input path, or the name of the unit on the map. It will remind you that there is no unit in Changsha and no way. In addition, we received a fax, saying that you want to order what goods, may wish to go to the other party's local industrial and commercial Red Shield network to check whether there is this unit

- Q: What are the main functions of construction equipment monitoring system?

- The total of the console cameras and auxiliary equipment (such as camera, PTZ, shield) control generally adopts the bus mode, a control signal to the camera near the terminal in the terminal box decoding, decoding box will total console from the control signal encoding solution, a control action command signal, a variety of actions to go camera control and auxiliary equipment (such as lens zoom, pan rotation etc.). In the case of some cameras that are close to the control center, in order to save money, the command signal, which is the "on or off" signal, can also be sent directly by the console. In short, according to the composition of the system and requirements, can be considered in order to complete the overall console design requirements or order requirements.

- Q: What are the principles, performances and uses of the commonly used construction machinery equipment?

- 2.: Principle: loader loader work, powered by a flywheel of the diesel engine to the hydraulic torque converter, the torque converter will drive to the gearbox, and before and after the output flange of the gearbox, the power output of the gearbox after the transmission shaft are respectively transmitted to the front and back drive axle to drive the wheels forward. Performance: 1) Central articulated frame, turning radius is small, flexible and convenient operation in narrow space; 2) using hydraulic mechanical transmission, according to the size of the external resistance and automatic stepless speed change, which can make full use of engine power, and improve the maneuverability, simplifies the loader operation. Is to protect the transmission parts and engine; 3) adopts full hydraulic steering, power shift transmission, hydraulic or flexible manipulation, portable and flexible machine; 4) stable and reliable operation; wide use of low-pressure off-road tires, rear axle swing, with good cross-country performance and through the performance by 5); gas cap oil disc brake system and brake foot up, emergency braking system, the braking performance is safe and reliable; 6) with advanced structure and bright cab. The air conditioning system operates more comfortably. Uses: loaders are mainly used for shovel, loading, unloading, transport of soil and stone a kind of bulk materials, rock and hard soil can also be slightly shovel operations.

- Q: What kind of electrical equipment do you have? What are the main components of each device?

- The utility model relates to a distribution box, belonging to a primary equipment in an electric equipment. Electrical equipment includes primary equipment and two equipment. Primary equipment is mainly power generation, power transmission, transmission, distribution, electricity and other direct generation, transmission and consumption of electrical energy equipment, such as generators, transformers, overhead lines, power distribution cabinets, switches, cabinets and so on. The two equipment is the equipment that controls, protects, measures and so on. Building or general buildings, such as cables, power distribution cabinets, motors, switches, sockets, lamps, air conditioners, electric water heaters, electricity meters, cameras, telephones, computers, etc., are electrical equipment.

- Q: What type of industry does the machinery and building accessories processing belong to?

- There are only three tax categories in our country: 1 consumption tax, 2 VAT, 3 special tax (agriculture). Therefore, as long as the manufacturing or processing of industrial value added tax on enterprises. It has nothing to do with the economic nature, classification and categories of an enterprise.

- Q: Where are the mechanical pressurization air supply facilities set up?

- When the smoke proof staircase and antechamber antechamber, fire elevator or common antechamber parts can be opened outside the window, can use the natural ventilation, resulting in a stairwell with or common antechamber in the use of natural smoke exhaust with pressurized air supply arrangement of diversified combinations, and the two exhaust can not be shared.

- Q: What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q: Mechanical bearings, all types? Roughly

- Spherical roller bearings have two raceways in the inner and outer ring raceways between spherical assembly, a drum shaped roller bearings. The center of curvature of the raceway of the outer race is consistent with the center of the bearing, so it has the same self-aligning function as the self-aligning ball bearing. When the axle and shell are bent, the axial load in two directions can be automatically adjusted. Radial load capacity, suitable for heavy load and impact load. Inner diameter is tapered bore bearings can be installed directly. Or the use of tight sets, the demolition cylinder installed on the cylindrical shaft. The cage uses a steel plate holder, a polyamide forming cage and a copper alloy car holder.

- Q: What are the sub projects of a construction project?

- Lime soil, sand and gravel foundation, geosynthetics foundation, fly ash foundation, dynamic compaction, foundation grouting, preloading foundation, vibroflotation foundation, jet grouting foundation, cement mixing pile foundation, soil and lime soil compaction pile foundation, cement fly ash gravel pile, cement soil pile foundation. Based on sand pile foundation

- Q: What functions should be achieved in mechanical structure design?

- The design of mechanical structure is based on the overall design, according to the principle of the program to determine and draw a specific structure, in order to reflect the required functions. Is the working principle of the abstract concrete into some parts, the specific content in determining the structure of the material, shape, size, tolerance, heat treatment and surface conditions at the same time, we must consider the process, strength, stiffness, accuracy, and other parts of the relationship between each other and other issues. So, the direct product structure design is the technical drawings, but the design work is not a simple mechanical drawing, drawing only express design language, specific integrated technology is the basic content of structural design.

Send your message to us

Whole Aluminum Formwork with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords