Whole Aluminum Formwork with Different Sizes Used in Large Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

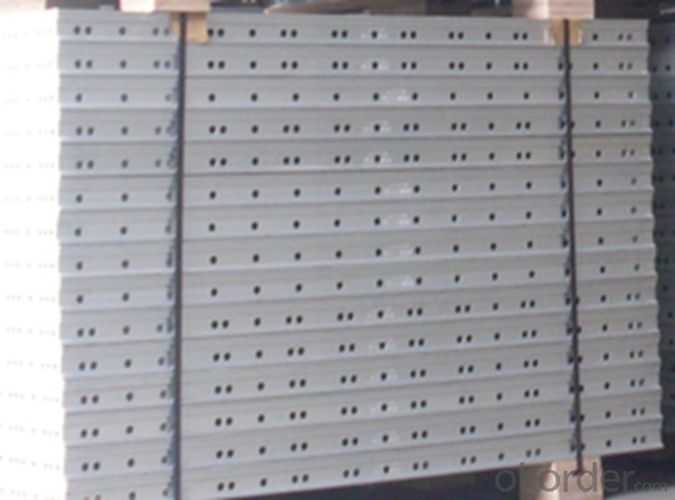

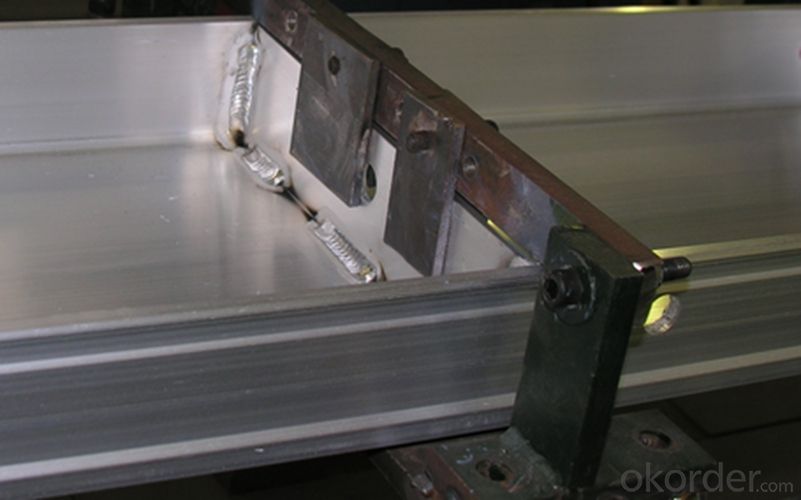

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

3. Whole Aluminum Formwork Images

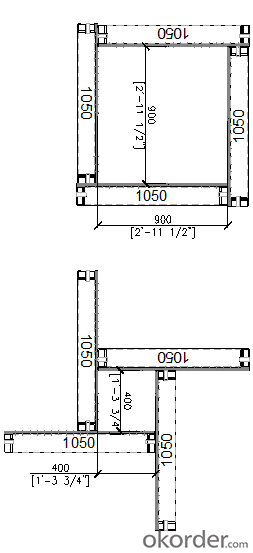

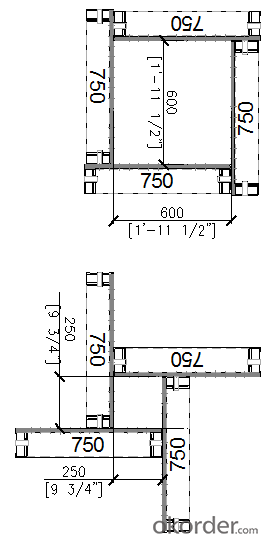

4.Whole Aluminum Formwork Specifications

1) MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2) DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3) StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4) StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Please feel free to customize.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale services?

Response will be carried out in 24hours after receiving any complain or request.

- Q: What are the sectors of machine building and parts processing?

- 1., industry generally refers to its production of similar products, or with the same process, or to provide similar labor services division of economic activities, categories.

- Q: What are the main functions of construction equipment monitoring system?

- To date, the console has always been built into blocks, in terms of control functions and number of cameras. Can be assembled according to requirements. In addition, the character generator is also arranged in the total time and address on the console, the date and time, minutes and seconds are displayed by this device, and be put in place to monitor the address and name display. It can be recorded on the video recorder, so that it will be convenient for future reference.

- Q: What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q: What is the use of spare parts prices in Chinese market by foreign companies?

- You might be gathering information for him. You have no data for one person, if there are several people? They can analyze a lot of things through big data. You can't find out, you're OK. Once you find out, your whole life is over.

- Q: How are the machine parts stacked?

- Classification ah! Put small pieces of different sizes and functions into boxes and attach labels; larger items can be placed outside in a certain order (for example, function, length, value, etc.)

- Q: What type of industry does the machinery and building accessories processing belong to?

- There are only three tax categories in our country: 1 consumption tax, 2 VAT, 3 special tax (agriculture). Therefore, as long as the manufacturing or processing of industrial value added tax on enterprises. It has nothing to do with the economic nature, classification and categories of an enterprise.

- Q: What are the world famous mechanical equipment exhibition?

- 3, the French international civil engineering and Construction Machinery Exhibition (INTERMAT) the European Construction Committee (CECE), founded in 1988, tenth in 2015, is one of the three famous exhibition of world engineering machinery and construction machinery field, three years. France INTERMAT exhibition exhibits covering mining machinery, earthmoving machinery, concrete machinery, lifting machinery, pavement and compaction machinery, piling machinery, industrial vehicles, pneumatic tools, drilling machinery, building materials machinery, mining machinery and other engineering and construction machinery and spare parts industry. Paris International Construction Machinery Exhibition in Europe - the Middle East - Africa (EMEA) region has a unique position.

- Q: Mechanical bearings, all types? Roughly

- Spherical roller bearings have two raceways in the inner and outer ring raceways between spherical assembly, a drum shaped roller bearings. The center of curvature of the raceway of the outer race is consistent with the center of the bearing, so it has the same self-aligning function as the self-aligning ball bearing. When the axle and shell are bent, the axial load in two directions can be automatically adjusted. Radial load capacity, suitable for heavy load and impact load. Inner diameter is tapered bore bearings can be installed directly. Or the use of tight sets, the demolition cylinder installed on the cylindrical shaft. The cage uses a steel plate holder, a polyamide forming cage and a copper alloy car holder.

- Q: What are the construction materials, components, fittings and equipment in construction?

- : construction engineering materials, components, fittings, equipment, each refers to: 1, engineering materials: engineering materials mainly refers to raw materials. Such as: sand, stone, steel, etc., there is no processing materials. 2, structural parts: the main structure here is the main structure of the building, the two structure and other accessories. Most of the semi-finished products and the structure of part of the installation accessories, such as: beam beam, continuous beam, beam, beam, cantilever beam, curved beam; steel, timber, concrete beam.

- Q: What are the sub projects of a construction project?

- Lime soil, sand and gravel foundation, geosynthetics foundation, fly ash foundation, dynamic compaction, foundation grouting, preloading foundation, vibroflotation foundation, jet grouting foundation, cement mixing pile foundation, soil and lime soil compaction pile foundation, cement fly ash gravel pile, cement soil pile foundation. Based on sand pile foundation

Send your message to us

Whole Aluminum Formwork with Different Sizes Used in Large Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords