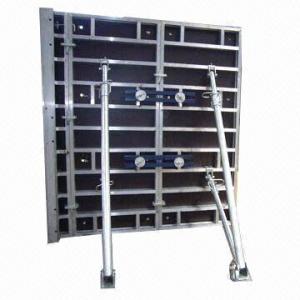

Whole Aluminum Formwork System for Supermarket Building

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum formwork Description

Easy and quick to remove, after pouring concrete:

Remove wall column within 24 hours;

Remove beam sides within 36 hours;

Remove beam bottom and bottom formwork within 48hours;

Remove load bearing pillars after 12 days;

Remove beam bottom bearing pillar after 14 days;

Remove cantilever pillar after 28 days;

3~4 days for one floor construction.

Raw material made by 6061-T6 aluminum;

Recycle use 150~300 times to make low cost

The average weight is 25kg/m2

Few instruments for installation

Average 20~30 m2 per day for one worker

Save 20%~30% workers than wooden formwork

Smooth concrete surface

Save plaster cost

All components are reusable

Clean and neat construction site

Usually 80% formwork can directly reuse

Renewable materials to save energy

Low carbon emissions

Comparasion of Aluminum formwork & wood formwork

NO. | Reference | Aluminum Formwork | Wood Formwork |

1 | Material cost (Included Support) | $183-216/m2 | $13--16/m2 |

2 | Turnaround times | 200times at least | 3-5times |

3 | Assembling and dismantling labor cost | $3.6-4.2/m2 | $4.2-4.7/m2 |

4 | Recovery value | $67/m2 | $0.8/m2 |

5 | Subtotal artificer materials | $4.4-4.9/m2 | $7.5-8/m2 |

6 | Leveling the wall plastering labor cost | $0.4/m2 | $2/m2 |

7 | Leveling the wall plastering material cost | $0.3/m2 | $2.6/m2 |

8 | Ergonomics | 20m2/day | 15m2/day |

9 | Final economic indicators | $5.9-6.4/m2 | $12-13/m2 |

Advantages of Aluminum Formwork / Shuttering System

1. Light weight, high strength and precision

The data has proved that the flexural strength of aluminum is triple higher than ordinary steel.With weight of 20-26KG/M2. Aluminum formwork is the lightest formwork for construction,which makes for easy handling.

2. Various sizes, high accuracy

The construction drawing is designed with strict structure, with little measurement error and high accuracy,which is very suitable for high rise buildings.

3. Safe and convenient construction

High loading capacity requires less use of props, reducing lost in material and labor. Workers can independently operate after simple training.

4. Long time used

With the lowest average lost, aluminum formworks can be used up to 300 times.

5. Widely applicable

The precise-designed formwork system applies to all kinds of building elements, such as the main wall, column, beams, stairs and balconies.

6. Excellent quality

The concrete surface is very smooth, so it can saved the swing cost and shorten the construction period.

7. High efficiency

According to different climatic conditions, the formworks can be removed in 18-36 hours.

8. Recyclable value

The used aluminum material is of greater recyclable value,several times higher than steel.

9. Independent support system

The gap between the formwork support is totally enough for passing, moving and pulling.

10. Dependable safety, environmental

The construction process is totally safe. Full aluminum structure leads to no galvanization and thus minimizes the pollution to our earth.

- Q: Case Study of Aluminum Alloy Formwork

- Aluminum alloy template lighter than the steel template, the use of fast assembly and disassembly system, moving components, lightweight and flexible, greatly reducing the amount of artificial, easy construction management. Aluminum alloy template is one of the most advanced templates, the construction company image is good. Design advanced early demolition system, to speed up the construction progress.

Send your message to us

Whole Aluminum Formwork System for Supermarket Building

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches