Whole Aluminum Formwork System For A Large Area Slab Formwork System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

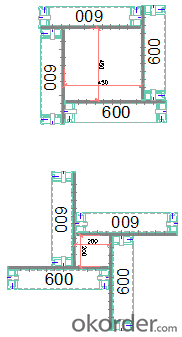

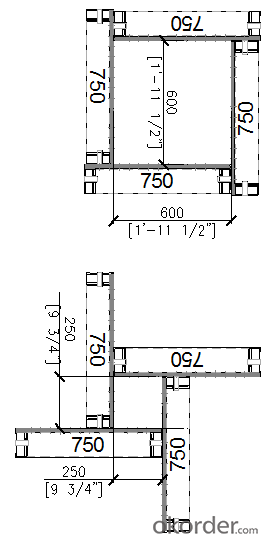

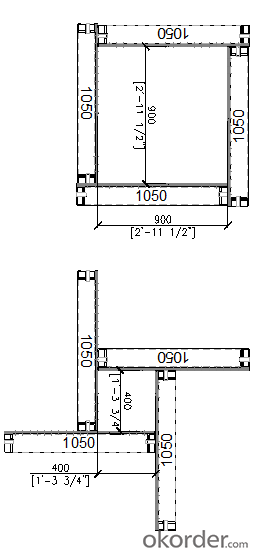

3. Whole Aluminum Formwork Images

.

4. Whole Aluminum Formwork Specifications

1: MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2: DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3:StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4:StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

.We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

-Packing: wood package and adhesive tape

-Shipping: by sea

-Shipping time: Normally small orders just takes 7 business days to arrive your hand;. When it comes to the customs declaration, it may need 2weeks.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- The distribution of the construction site, construction machinery and electric hand-held electric tools, lighting, construction site construction site: risk factors and lightning protection, the construction site of common electrical tools and instruments, the construction site of the electricity management, common electrical fault, accidents and accident cases.

- Q: Where was the construction machinery conference held in 2015?

- 2015 Bada international construction machinery exhibition, exhibition information time: June 5, 2015 (Friday) - 7 day (Sunday) location: Shandong Bada international engineering machinery City Theme: cooperation, win-win, innovation, development, guidance: National Quality Supervision and inspection center of engineering machinery, Shandong Machinery Industry Association, Shandong province transportation and Logistics Association Shandong, Shandong Jiaotong University, Shandong Institute of road, economic development zone of Qihe Province

- Q: Changsha Sanlian Building Machinery Fittings Factory

- The company in Changsha Hongdun business online can not find, provided by his address: two Changsha section of Xingsha Economic Development Zone Yuan Ming Road, I checked 114 specially call 12580 to booking the hotel near the road, not the road. Definitely a liar.

- Q: What is the use of spare parts prices in Chinese market by foreign companies?

- You might be gathering information for him. You have no data for one person, if there are several people? They can analyze a lot of things through big data. You can't find out, you're OK. Once you find out, your whole life is over.

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product qualification certificate means the qualified certificate, qualified label or qualified seal issued by the manufacturer to indicate the quality of the products manufactured by the factory and qualified on the package of the product or product. This is the producer's guarantee of the quality of its products, and also the obligation of a product to be stipulated by the law.

- Q: China mechanical net

- There are mechanical product development and design, mechanical equipment transformation, mechanical equipment maintenance, data inquiries, standard inquiries, mechanical professional translation, mechanical CAD and other mechanical and technical services.

- Q: Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

- Q: What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

- Q: What is the difference and connection between equipment manufacturing and machine building?

- In accordance with the standards of classification, including metal products, general machinery manufacturing, machinery manufacturing, transportation equipment manufacturing, electronic and communication equipment manufacturing industry, electrical machinery and equipment manufacturing, instrumentation and office machinery manufacturing seven deducted 186 small consumer related manufacturing industry after class. Equivalent to the European countries referred to as "capital goods manufacturing", that is, we often say "the production of means of production industry."".

Send your message to us

Whole Aluminum Formwork System For A Large Area Slab Formwork System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords