White Polyurethane/PU Food Grade Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Polyurethane/PU Food Grade Conveyor Belt

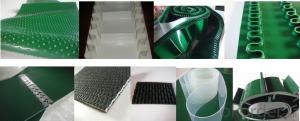

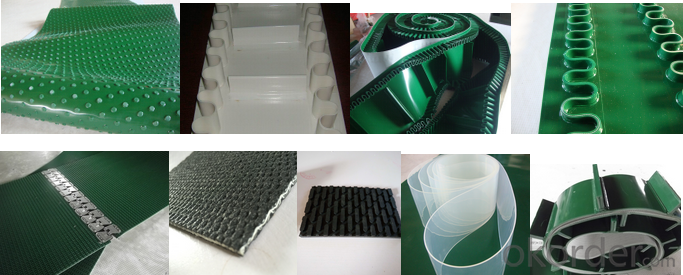

PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q: What are the dimensions of a standard olive net?

- The dimensions of a standard olive net can vary, but they typically range from 10 to 20 feet in width and 50 to 100 feet in length.

- Q: How can I remove the scratches on the plastic?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization (macromolecules), commonly known as plastic resin (plastics) or (resin), can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

- Q: What is the most effective way to reduce the environmental pollution caused by plastic bags?

- White pollution is one of the plastic packages that are difficult to degrade. Disposable foam tableware such as fast and we used plastic bags and so on. It is very serious environmental pollution, buried in the soil is difficult to decompose, the soil will lead to reduced capacity, if the burning causes air pollution, so I do not advocate or less with it, buy the best own tools to reduce its use.

- Q: Can olive nets be used in combination with cover cropping methods?

- Yes, olive nets can be used in combination with cover cropping methods. Cover cropping involves growing a variety of plants to protect and enrich the soil, while olive nets are used to catch falling olives during harvest. By implementing cover crops in between olive tree rows, the nets can still be used effectively without interfering with the growth and benefits of cover crops. This combined approach can enhance soil health, prevent erosion, and improve overall olive tree productivity.

- Q: How do olive nets prevent fruit contamination from animal droppings?

- Olive nets prevent fruit contamination from animal droppings by acting as a physical barrier, preventing animals from accessing the trees and dropping feces onto the fruit.

- Q: How do olive nets affect the growth and health of olive trees?

- Olive nets can positively affect the growth and health of olive trees by providing protection against pests and extreme weather conditions. These nets act as a barrier, preventing insects and birds from damaging the fruit and foliage, which can lead to reduced yield and overall tree health. Additionally, olive nets can shield the trees from excessive sunlight, wind, and hail, helping to maintain optimal growing conditions. Ultimately, the use of olive nets can contribute to the overall productivity and well-being of olive trees.

- Q: Can olive nets be used for olive tree training from seedlings?

- Yes, olive nets can be used for olive tree training from seedlings. Olive nets are commonly used to support and train young olive trees by guiding their growth in a desired direction. The nets provide stability and prevent the seedlings from bending or breaking under their own weight. By attaching the nets to sturdy posts, the seedlings can be trained to grow vertically, allowing for better light exposure and air circulation.

- Q: Can olive nets be used for both traditional and hydroponic olive tree pruning?

- Yes, olive nets can be used for both traditional and hydroponic olive tree pruning. Olive nets are commonly used to collect olives during the harvest season, regardless of the cultivation method. They are versatile and effective in preventing olives from falling to the ground and getting damaged, making them suitable for both traditional and hydroponic olive tree pruning.

- Q: Can olive nets be used on trees of different sizes?

- Yes, olive nets can be used on trees of different sizes. Olive nets are versatile and can be adjusted and secured to fit trees of varying heights and widths, making them suitable for use on a range of olive tree sizes.

- Q: What does plastic melt mean?

- Refers to the plastic melt index, now according to the national standard requirements, known as plastic melt flow rate, unit is: grams /10 minutes.

Send your message to us

White Polyurethane/PU Food Grade Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords