White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

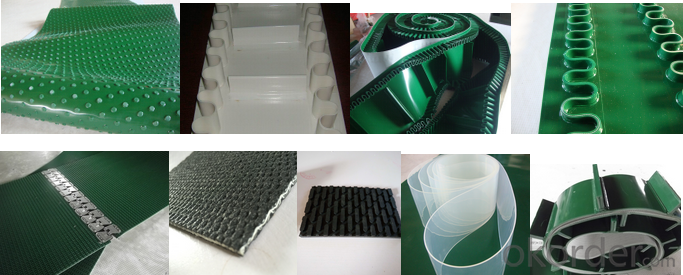

PU Conveyor Belt

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

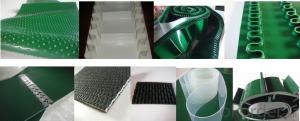

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Just contact us freely if you need any PVC/PU conveyor belt,thank you!

- Q: Are there any specific guidelines for using olive nets on old or mature olive trees?

- Yes, there are specific guidelines for using olive nets on old or mature olive trees. It is important to choose a net that is large enough to cover the entire tree canopy and secure it properly to prevent any gaps. The net should be installed before the olives ripen and left on until the harvest is complete. Regular inspection and maintenance of the nets are necessary to prevent any damage to the tree or olives. Additionally, it is recommended to consult with local olive growers or agricultural experts for specific guidelines tailored to the particular variety of olive tree and local conditions.

- Q: Are there any disadvantages to using olive nets?

- Yes, there are a few disadvantages to using olive nets. Firstly, olive nets can be costly to purchase and install, especially for large-scale olive groves. Secondly, they require regular maintenance and cleaning to prevent debris accumulation, which can be time-consuming and labor-intensive. Additionally, olive nets can reduce air circulation and sunlight exposure, potentially increasing the risk of fungal diseases and affecting fruit quality. Lastly, harvesting olives using nets can be challenging and may result in damage to the tree branches or fruit if not done carefully.

- Q: What are the codes for the plastics and plastics industries in the industry?

- Manufacturing, plastic packing box and container manufacturing, plastic shoes manufacturing synthetic leather, plastic industry is in plastic processing as the core, a whole including plastic resins, additives and additives, plastics processing machinery and tooling. The future of domestic plastic products market mainly focuses on agricultural plastic products.

- Q: Are there any alternatives to olive nets for olive harvesting?

- Yes, there are several alternatives to olive nets for olive harvesting. Some common alternatives include manual handpicking, mechanical harvesters, and canopy shakers. Manual handpicking involves individuals picking olives directly from the tree by hand. Mechanical harvesters are machines designed to shake the tree or branches, causing olives to fall onto a collection system. Canopy shakers are devices that attach to the tree trunk and vibrate the branches to release olives. These alternatives offer different options depending on the scale and specific requirements of the olive harvesting operation.

- Q: How do plastics weld?

- Plastic welding is limited to thermoplastic welding because only thermoplastics can be melted or softened while they are heated, while thermosetting plastics cannot be softened and remelted while they are heated.Hot air welding oxyacetylene similar to metal, but the latter with the former fire hot air heating. Hot gas welding process, the welding torch from the hot gas stream (typically 200 to 300 degrees Celsius temperature, flow rate of 15 ~ 60L/min) and the filler rod and welding pieces of the heating surface, when the material softening reached sticky state, filling rod continuous pressure into the weld. The filling bar material is the same as that of the base metal, usually round (about 3mm in diameter), and is welded by multiple bead welding. One drawback of the round filling rod is that the hollow bubbles are easily entrapped in the weld during the multi pass process, resulting in lower strength. This problem can be solved by using a triangular section welded rod. Typical materials for hot air welding include polyvinyl chloride, polyethylene, polypropylene, plexiglass, polycarbonate, POM, polystyrene, nylon, ABS and so on. The main advantage of hot gas welding is adaptive (flexibility), portable equipment and processing of large, complex parts can be simple. Hot air welding is suitable for irregular structures, but it is slow and the quality of welding depends largely on the skill of the operator. Therefore, it is seldom used in mass production, but it is suitable for repair operation.

- Q: How many grades are there in the plastic block? How to divide?

- UL is a plastic material standard test piece by spontaneous combustion flame after the combustion time, combustion speed, falling particle state to set the plastic material fire resistance rating, according to the level of quality, followed by HB, V2, V1, V0, 5V, VTM-0, VTM-1 and thin material grade, VTM-2, and foam material grade HBF, HF-1, HF-2.

- Q: How do olive nets help in reducing the risk of fruit rot?

- Olive nets help in reducing the risk of fruit rot by acting as a protective barrier between the olives and the ground. These nets prevent direct contact between the olives and the soil, which can harbor pathogens and cause fruit rot. Additionally, the nets also provide shade and airflow, creating a favorable environment for the olives to dry quickly after rain or irrigation, further reducing the risk of fruit rot.

- Q: Can olive nets be used to extend the harvesting season?

- Yes, olive nets can be used to extend the harvesting season. These nets are commonly used in olive orchards to catch and collect ripe olives as they fall from the trees, preventing them from being damaged or lost. By using olive nets, farmers can start harvesting earlier and continue harvesting for a longer period of time, effectively extending the harvesting season.

- Q: Can olive nets be used in olive groves with limited water availability?

- Yes, olive nets can be used in olive groves with limited water availability. Olive nets are primarily used to collect the olives during the harvest season and do not directly impact water availability. However, it is important to manage water resources efficiently in olive groves with limited water availability to ensure optimal growth and productivity of the olive trees.

- Q: Can olive nets be used in different soil types?

- Yes, olive nets can be used in different soil types. The type of soil does not impact the functionality or effectiveness of the olive nets.

Send your message to us

White Green Blue Food Grade PU Conveyor Belt for Biscuit Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords