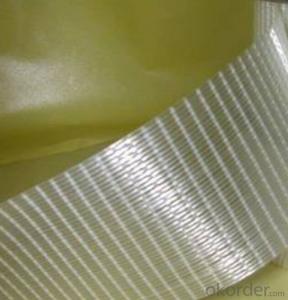

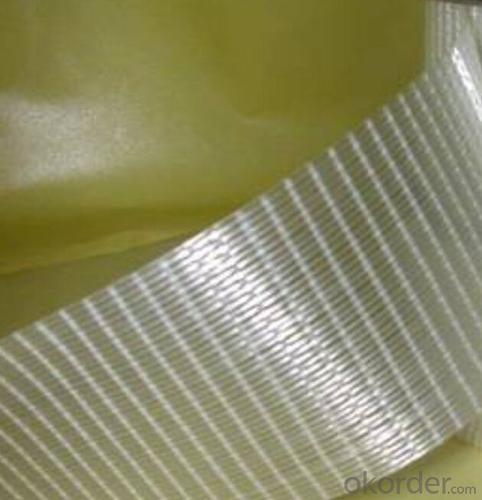

White Fiberglass Mesh - Stone Backing Mesh, 65g/m2, 20*10/inch, Soft and Flexible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

FOB Price of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible US $0.22/ Square Meter

MOQ of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible: 10000 Square Meters

Supply Ability of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible: 6000000 Square Meters per Month

Payment Terms of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible: L/C,T/T

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Specifications of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Place of Origin: China (Mainland)

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Brand Name: CMAX

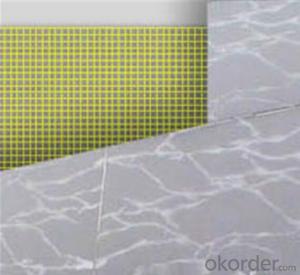

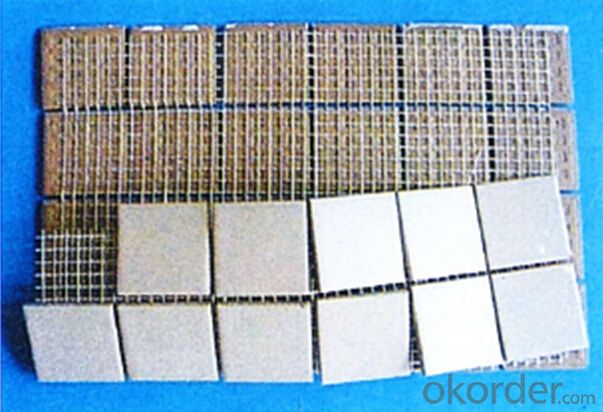

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Application: Wall Materials

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Width: 1M-2M

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Size: 5*5/ INCH

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Weight: 40gsm to 200gsm

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Weave Type: Plain Woven

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Yarn Type: C-Glass

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Alkali Content: Medium

Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible Standing Temperature: 500℃

Product information of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Name: Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Use best fiberglass yarn and best glue

Clear and beautiful Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

High strength Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

30 years experience of manufacturing Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Excellent Priced Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

FAQ of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Q: What is Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Coated Alkali-resistant Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible

Weight: 65g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Four years under normal weather conditions and use .

Q: What is the package of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Stone Backing Mesh, 65g/m2, 20*10/Inch, Soft and flexible?

Production periods: 30days for 1X40HQ.

- Q: What is the base material of fiberglass mesh?

- Of course, its base material is glass fiber. You said it was rough, probably the reason wass that in the process of producing glass fiber, immature technology caused broken filament, and after treatment, the adhesive?sticker, alkali-resistant glue or weather-proof glue was unevenly attached on the surface. So it looks rough. This is just the unqualified product in production process, and there isn't any counterfeit product. These product are not beautiful and their strength will be lower than that of qualified products. (The intensity of different mesh will have different degrees of decline: generally, the largest mesh opening is, the greater will the strength decline; conversely, the smaller mesh opening is, the smaller will the strength decline).

- Q: What's the meaning of hanging glass fiber net on the wall? Is it necessary?

- If your house is a frame structure, that is, reinforced concrete pouring, there is no need for that.

- Q: Glass fiber gridding cloth is easy to be broken after being glued.

- The glue matters or the baking process matters.

- Q: What is the function of exterior walls insulation alkali-resistant mesh?

- Alkali-resistant mesh insulation of exterior walls can enhance its resistance to weather so that it can withstand stress changes without cracking, so as to obtain long-term waterprof effects and avoid roofing leakage to bring discomfort and inconvenience.

- Q: What do you smear before making the Mesh?

- The wall adhesive is used to moisture-proof and mould proof as the same as the function of the base membrane of wallpaper.

- Q: Is it possible to crack the fiberglass net for the exterior wall painting?

- It's the barbed wire or the glass fiber net, which is usually attached to the wall and the beam, where the wall meets the post, because they are easy to crack

- Q: For the mesh of cleaning wall, is nylon fabric or fiberglass mesh better?

- Fiberglass mesh is absolutely better. Owing to its no-ductility, the cleaned wall is not easy to crack.

- Q: What kinds of industrial cloth are there? What kind of cloths and procedures are employed?

- I do not know what you mean by so-called industrial cloth. In fact, there are several meanings about cloth. According to the material of the fabric, it is then referred to the textile fibers. Despite the wide variety of textile fibers, but basically it can be divided into natural fiber and chemical fiber : 1. natural fiber refers to textile fibers that have been existing in the natural world, or directly obtained textile fibers from cultured animal . 2. Chemical fiber is a kind of textile fibers which make natural or synthetic polymers as raw material, and manufactured through a certain of method. 3 Artificial fiber refers to processed fibers whihch capitalize on the natural polymer manmade fibers (such as wood, bagasse or animal fibers, etc.) as raw material. 4. The synthetic fibers, with oil, coal, natural gas and a number of agricultural products as raw materials, are formed by synthetic polymer spinning. When mentioning procedures, they are usually secrets unrevealed!

- Q: What role does exterior wall thermal insulation mesh cloth play?

- Wall mesh, also called glass fiber wall mesh, with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into.

- Q: What glue can be used to test fiberglass mesh finished product, the gold pot? And whst is the matching of glue?

- Imitated gold pot mesh is never as good as gold pot mesh in quality. 1. This is one aspect/part of imitated gold pot mesh. The product is highly praised as good quality by mass people. The appearance of imitated gold pot is the same as that of gold pot mesh. 3. The weft is olla yarn, so it is called imitated gold pot. Our factory chiefly produces special mesh for external wall insulation, 60cm mesh and so on. Firstly, in terms of the texture, the warp of imitaed gold pot is gold pot yarn. People engaged in external wall imsulation have good knowledge of imitated gold pot mesh ang the rpoduct. Extruded sheet needs mesh, but there is few people who quite know about it. 2. Then, this is a reason that it is called imitated gold pot. Fiberglass mesh and alkali resistant mesh. Here I will give you an explanation that how imitated gold pot mesh is defined.

Send your message to us

White Fiberglass Mesh - Stone Backing Mesh, 65g/m2, 20*10/inch, Soft and Flexible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords