Mild Steel Welding Rod 2.0MM X 300MM Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Welding Rod Description:

E6010 This electrode is used for all position welding using DCRP.

produces a deep penetrating weld and works well on dirty,rusted, or painted metals

E6011 This electrode has the same characteristics of the E6010, but can be used with AC and DC currents.

E6013 This electrode can be used with AC and DC currents.

produces a medium penetrating weld with a superior weld bead appearance.

E7018 This electrode is known as a low hydrogen electrode and can be used with AC or DC.

The coating on the electrode has a low moisture content that reduces the introduction of hydrogen into the weld. lectrode can produce welds of ray quality with medium penetration.

(Note, this electrode must be kept dry. If it gets wet, it must be dried in a rod oven before use.)

2.Main Features of Welding Rod:

1): Durable, strict quality management and control.

2): High precision machining equipments guarantee good quality.

3): Smooth surface. No defects. Continuous skill improvements.

4): Quick delivery, competitive Chinese price. Low MOQ.

5): Our Company is specialized in machining service on precise mechanical parts; we are producing high precision parts for military enterprise

6): We have design team to develop new skill and new products to meet requirements of markets.

7): Good service, when customers have problems during use, we will surely try our best to solve them.

8): High professional employees have good emergency-dealing ability during production.

9): Surface treatment can be nickel, galvanized and painted, or based on the requirements of customers.

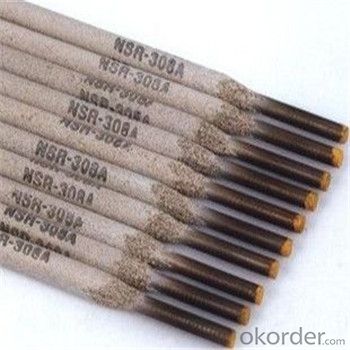

3. Welding Rod Images

4. Welding Rod Specification

Chemical Composition | C | Mn | Si | S | P |

Guarantee Value | ≤0.12 | 0.3-0.6 | ≤0.35 | ≤0.035 | ≤0.040 |

Mechanical Properties of Deposited Metal

Test Item | Rm(MPa) | ReL(Mpa) | A(%) | KV2(J) | KV2(J) |

Guarantee Value | ≥420 | ≥330 | ≥17 | -(normal temperature) | -(0℃) |

Reference Current (AC, DC)

Electrode Diameter(mm) | φ2.0 | φ2.5 | φ3.2 | φ4.0 | φ5.0 |

Length(mm) | 300 | 300(350) | 350 | 400 | 400 |

Welding Current (A) | 40~70 | 55~95 | 80~130 | 120~180 | 160~230 |

V-up, OH | 35~60 | 45~90 | 60~120 | 100~160 | 120~200 |

5.FAQ

Q: How do you ship the Welding Rod?

A: Usually by sea.

Q: Are you a manufacturer?

A: Yes, we have been in providing the professional products in Welding Rod over 10 years.

Q: Can I get the sample?

A: Yes, free samples are prepared for your test.

- Q: Can welding of stainless steel plate and ordinary steel pipe be welded with thj422 welding rod?

- J: stands for structural steel welding rod.42: two figures indicate that the minimum value of tensile strength of deposited metal is 42kgf/mm2 (412MPa), and the minimum value of the yield strength of deposited metal is 34kgf/mm2 (430MPa).2: third digit "2" indicates that the type of coating is titanium calcium type, direct current or AC power supply.According to the national standard GB/T5117 - 95, it is E4303 type ordinary carbon steel welding rod.Two, stainless steel and ordinary steel can be welded, the electrodes used must be the welding of the stainless steel or stainless steel welding rod or wire E31015 E31016.Three, in general, does not recommend the use of stainless steel and carbon steel welding in one place, the use of flange of stainless steel and carbon steel is more appropriate, because long-term exposure, will produce "carburization reaction", the impact characteristics of stainless steel.

- Q: Requirements for welding electrodes for temperature and humidity

- Storage should be kept at 10---25 degrees Celsius and less than 50% relative humidity.

- Q: What kind of welding rod used for cast steel?

- Cast steel can be divided according to the composition of low carbon steel, medium carbon steel, different components of the electrodes used is not the same, if it is a low carbon composition, the common electrode, such as E4303 (J422) on it; if it is steel components, should be used in high strength structural steel electrode, such as E5015 (J507) E5515 (J557), welding welding and preheating, to prevent cracks.

- Q: How can I distinguish the basic electrode or the acid welding electrode from the welding rod number?What are the basic electrode models?What are the types of acid electrodes?

- The number of electrodes from 0 to 6 is acidic, and 7 to 9 is alkaline

- Q: J422 electrodes are marked with "THJ422". What does TH represent?

- J422 is the brand of welding rod GB. As for the TH is the enterprise stipulated grades, the first letter T should be on behalf of the welding electrode (strip of the first letter); second letters H, should be related to the electrode trademark or manufacturer's name.

- Q: In the pipe welding, a welding rod welding in the replacement of an electrode should be how to deal with joints?

- 1, if the strict requirements for pipeline welding, portable welder hammer medicine skin clean, in a welding rod arc welding joint has less to stay in the rear has deposited metal (no more than a centimeter can) for a moment, a swing, further the welding slag burn surface welding quality;2, in large long-distance pipeline, welding joints must be cleaned with a sand turbine, and then the next step of welding.

- Q: 302 which kind of electrode should be used for welding stainless steel with iron?

- A302 electrode can be cheap and matching, pay attention to welding current as small as possible, the electrode diameter as far as possible the use of small diameter welding rod, welding rod arc heat deviation to the stainless steel side.

- Q: What kind of welding rod should be used for welding cast iron? 506?

- Stainless steel electrode

- Q: What kind of welding rod or welding wire for welding Q245R steel?

- J427 for welding rod, 50-6 for welding wire.

- Q: What kind of welding rod should be used for welding cast steel parts?

- Ordinary steel welding, according to the general steel strength to choose, most of the structural steel welding rod, according to the strength of the cast steel of different levels, in turn can choose the type of electrode (or model) with J42 * (E43 * *), J50 * (E50 * *), J55 * (E55 * *)... Etc...

Send your message to us

Mild Steel Welding Rod 2.0MM X 300MM Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords