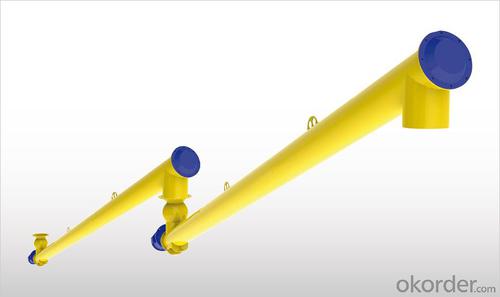

WAM Filler Dust Screw Feeders & Conveyors THF-TCF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The THF / TCF Screw Feeder and Conveyor range for Filler Dust is a specialised product line for the Asphalt Mixing industry.

THF / TCF Filler Dust Screw Feeders and Conveyors are highly versatile offering numerous solutions for feeding or conveying fine, dusty powders. THF / TCF are manufactured from carbon steel with a suitable surface finishing. They are made up from a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a centre pipe with a coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft seal suitable for filler dust. This type of screw, which comes without intermediate bearings, is equipped with a gear motor that suits the application.

Function

THF / TCF Screw Feeders and Conveyors for Filler Dust are designed to match the main requirements of the asphalt industry in feeding and conveying both hot and cold filler dust in stationary asphalt plants, at one end from the central dust filter and at the other end from the storage silos to the weigh hopper of the mixing plant. Wide spans are reached in a piggyback configuration. Thanks to the modular structure of the screws, various solutions are possible in terms of performance and component configuration.

Features

High performance in feeding and conveying

High-efficiency WAM power transmissions

Chain coupling power transmission where needed

Greased seals for hot/cold filler dust

Universal inlet/outlet spouts with optimised height measurement

Absence of intermediate bearings

Piggyback configuration

Benefits

Reduced overall dimensions

Easy assembly

Maintenance-friendly design

All components for standard configuration available from stock

Options

Connecting flanges

Adjustable pipe clamp supports

Send your message to us

WAM Filler Dust Screw Feeders & Conveyors THF-TCF

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords