VIP Nanometer Micropore Insulating Board for Foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characteristics

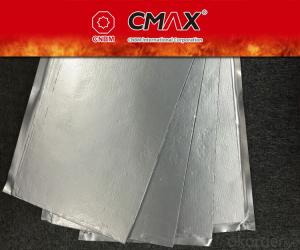

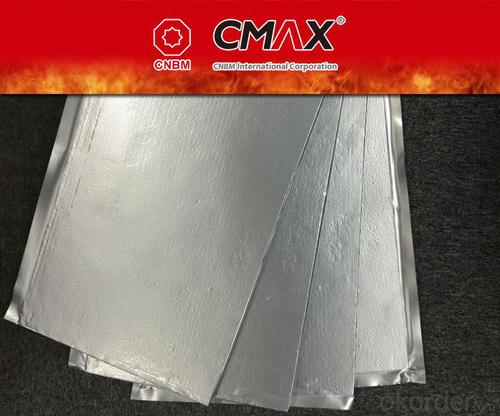

Nanometer Micropore Insulating Board for Foundrymaterial with an extremely low coefficient of thermal conductivity, i.e. with very good insulating properties.

Nanometer Micropore Insulating Board for Foundryconsists of inorganic

silicates. The main constituent is fumed silica, the other components are opacifiers for minimizing infrared radiation.

Nanometer Micropore Insulating Board for Foundry (core material) is not flammable and meets the requirements acc.

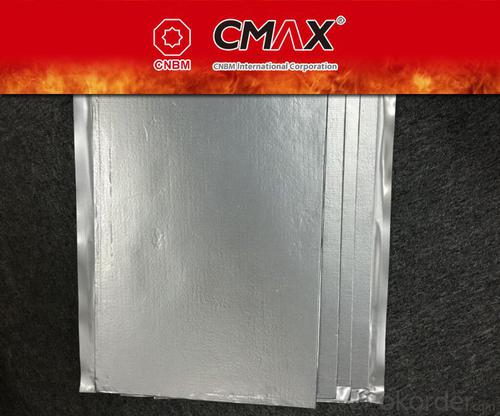

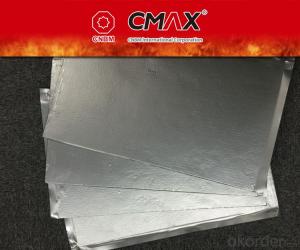

Nanometer Micropore Insulating Board for Foundry is heat sealed in a laminated aluminum foil system.

It can be used up to a maximum application temperature of 1100 °C.

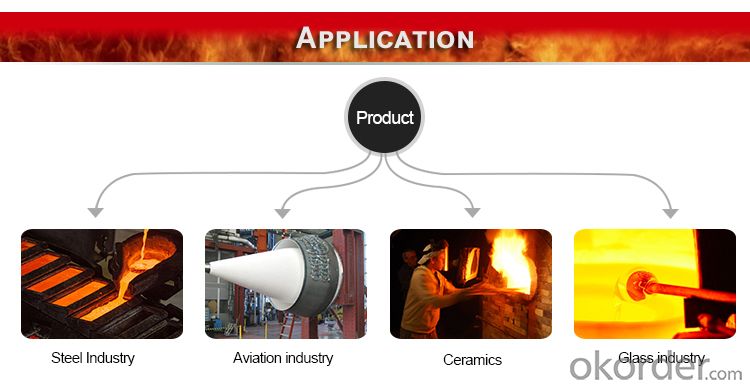

Application

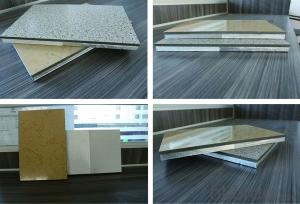

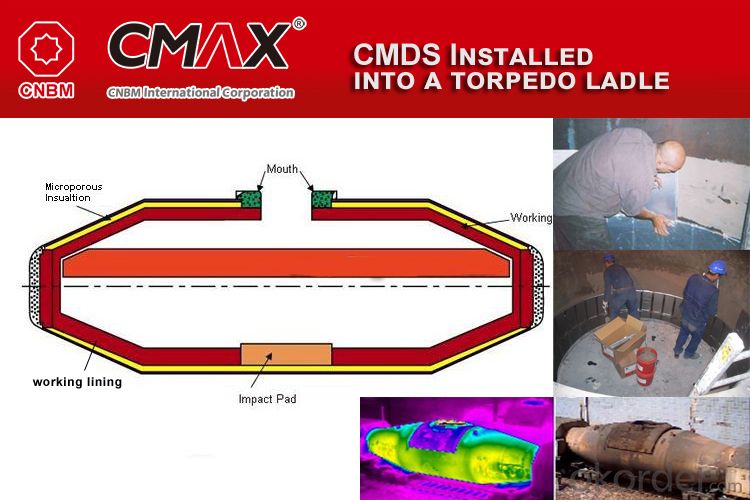

Super include back-up insulation in the steel and nonferrous metals industry.

fulfills several functions, such as:

· Precisely controlled energy emission

· Reduction of weight and volume

· Increase of heat retention

· Increased effective volume

Successfully used as insulation material in the following areas:

· Heat treatment systems for metals

· Heat treatment systems for glass

· Fire protection equipment

· Electronic devices

· Measurement equipment

· Plant construction parts

· Parts in the automotive industry

· Chimneys, pipes and diesel exhaust systems

Form of delivery

1. Standard sizes:

· 500 mm * 250 mm * X

· 500 mm * 500 mm * X

· 1000 mm * 500 mm * X

2. Standard thicknesses (X):

· 3 mm, 5 mm, 7 mm, 10 mm

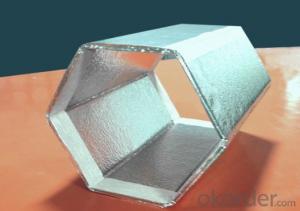

3. Complex geometries and special formats

available on request

Restrictions on Applications

Nanometer Micropore Insulating Board for Foundry is sensitive to all liquids that can wet it, such as water, oil, petroleum spirit, since they can destroy the nanoporous structure.

For the aforementioned reasons, care should be taken not to damage the cover film before or during

installation.

Damage or cut edges must therefore be protection with an Aluminum adhesive tape.

Shelf life

Nanometer Micropore Insulating Board for Foundry ,If properly stored, has an unlimited shelf life and must be handled and stored in dry conditions.

Nanometer Micropore Insulating Board is resistant to diffusion by atmospheric humidity (water vapor).

Composition

Silicon dioxide SiO2 approx. 50 %

Zirconium silicate ZrSiO4 approx. 45 %

Others approx. 5 %

Electrical resistance

Panel unhardened

Stored under dry conditions > 2000 MO

Thermal shock resistance

Nanometer Micropore Insulating Board for Foundry is insensitive to high and low temperature thermal shocks.

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- The traditional ceiling color steel tile composite composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K) above), plus There is a gap between the foam board and the board, the temperature is very serious, the comprehensive thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because in the construction of the use of direct spray molding technology, so that the polyurethane foam layer is not the overall burden of sewing the body to form a complete impermeability, fundamentally put an end to the possible deep Sex. Which play a preservative effect.

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- This place is different in different places, the calculation is not the same. We are here so: independent columns need to calculate the scaffolding to (peripheral circumference +3.6) multiplied by the column height calculation, 3.6 meters below the single row of scaffolding, 3.6 meters above the corresponding height of the double row. With the overall beam of the beam does not calculate the scaffolding. You say the frame column, to distinguish between different situations.

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- Aluminum generally refers to anodized aluminum, not magnesium alloy. Apple, Dell alien field arc spot some of the old roar M18x (note only M18x is, other models are not) XPS series, all the super class such as Acer hummingbird, Lenovo U300s

- Q: What is the best insulation material? To be waterproof.

- XPS board has a unique micro-closed-cell honeycomb structure, compared with the EPS board, with a high density, high compression performance, thermal conductivity is small [building buildings commonly used XPS board at room temperature thermal conductivity of about 0

- Q: External wall insulation material which is good, external wall insulation materials

- Feeling the effect of such lights is greater than the application, really is not in the use of the car, the flexible fiber is generally the car lights or position lights, light time is short; home decoration to long bright, LED on the ruthless Some of the The new light guide itself is fixed, the greater the power of the LED, the lighter the optical fiber, but the need for high-power LED heat, so when you install the attention, low-power LED if you can make light guide you The effect is not good, you need to choose to choose high-power, you have to consider to LED cooling, heat is not good, then said in front of the light failure, secretly secretly Empty Are very simple, do not worry

Send your message to us

VIP Nanometer Micropore Insulating Board for Foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords