Vinyl Packaging Tape for Auto and Normal Painting Masking Reviews

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Masking Tape of Auto and Normal Painting

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

Size of Masking Tape of Auto and Normal Painting

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Masking Tape of Auto and Normal Painting

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

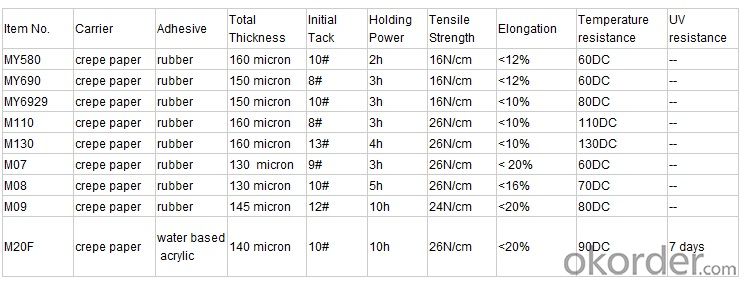

Technical Data of Masking Tape of Auto and Normal Painting

Picture Show of Masking Tape of Auto and Normal Painting

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape safe for use on children's toys or products?

- No, packaging tape is not safe for use on children's toys or products. It is not designed or tested to meet the safety standards required for products intended for children. It is important to use child-safe materials and adhere to safety guidelines when it comes to products that will be used by children.

- Q: What are the advantages of using packaging tape over other sealing methods?

- Using packaging tape has numerous advantages compared to other sealing methods. Firstly, it provides a robust and secure seal capable of withstanding the challenges of shipping and handling. Its adhesive properties allow it to stick to various surfaces like cardboard, plastic, and metal, ensuring the package remains intact throughout its journey. Secondly, packaging tape is user-friendly and can be applied quickly to seal a package. Unlike glue or staples, it does not require any additional tools or equipment, saving time and enabling efficient packaging processes. Moreover, packaging tape offers versatility in terms of size and strength. It comes in different widths and thicknesses, allowing for customization according to the specific requirements of the package. Whether sealing a small envelope or a large box, there is a packaging tape option that suits your needs. Another advantage of packaging tape is its cost-effectiveness. It is generally more affordable compared to other sealing methods, making it an economical solution for businesses and individuals who frequently ship or package items. Furthermore, packaging tape is tamper-evident, adding an extra layer of security. Once applied, any attempt to tamper with the package will be apparent due to the broken or damaged tape seal. This serves as a deterrent against theft and offers peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable without leaving any residue or damaging the packaging materials. This is particularly useful for packages that may require resealing or for recipients who may want to reuse the packaging. In conclusion, the advantages of using packaging tape include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Certainly! Packaging tape is indeed suitable for sealing household or kitchen items. With its versatility as an adhesive tape, it is widely employed for sealing cardboard boxes. However, it can also serve the purpose of sealing numerous items found in the household or kitchen. Whether you require sealing food containers, plastic bags, or even small appliances, packaging tape guarantees a robust and reliable seal. To optimize its adhesive strength, it is crucial to ensure that the surface is both clean and dry prior to applying the tape.

- Q: Can packaging tape be used for sealing containers with liquids?

- Yes, packaging tape can be used for sealing containers with liquids. However, it is important to note that not all packaging tapes are designed to withstand contact with liquids for extended periods of time. If you are sealing containers with liquids, it is recommended to use packaging tape that is specifically designed for this purpose, such as water-resistant or waterproof tape. These tapes are generally more durable and have enhanced adhesive properties to ensure a secure seal and prevent leakage. Additionally, it is advisable to properly clean and dry the surface of the container before applying the tape to ensure optimal adhesion.

- Q: What are the alternatives to packaging tape?

- There are numerous options available for securing packages or boxes instead of using packaging tape. Some of the popular choices are as follows: 1. Duct Tape: Known for its durability and ability to adhere to different surfaces, duct tape is a robust adhesive tape that serves as a viable alternative to packaging tape. 2. Masking Tape: Unlike packaging tape, masking tape possesses a lower level of stickiness. It is commonly utilized in painting or crafting projects, but can also be employed for securing packages. 3. String or Twine: A package can be secured by wrapping string or twine around the box and tying it tightly. This method is often used for packages that do not require a strong adhesive. 4. Packaging Straps: Made from plastic or polyester, packaging straps can be tightly fastened around the box to ensure secure packaging. They provide a reliable and sturdy alternative to packaging tape. 5. Adhesive Glue: For smaller packages or envelopes, adhesive glue can be used instead of packaging tape. It is crucial to select a strong glue that will securely seal the package. 6. Paper or Kraft Tape: Water-activated paper or kraft tape is commonly employed for sealing packages. The adhesive is activated by wetting the tape, resulting in a strong and secure seal. 7. Zip Ties: Zip ties, which are plastic ties, are often used for securely fastening large or heavy packages by tightly encircling the box. To determine the most suitable alternative to packaging tape, it is vital to assess the specific requirements of the package, including its size, weight, and handling needs.

- Q: What are the benefits of using silent packaging tape?

- There are several benefits of using silent packaging tape. Firstly, silent packaging tape provides a noise-free packaging experience. This is particularly beneficial in environments where silence is necessary, such as in offices, libraries, or other quiet spaces. By eliminating the loud noise typically associated with traditional packaging tape, silent tape helps maintain a peaceful and calm atmosphere. Secondly, silent packaging tape is preferred by employees who handle packaging tasks on a regular basis. The absence of noise during the taping process reduces the risk of noise-induced stress or fatigue, contributing to a more comfortable working environment. This can lead to increased productivity and employee satisfaction. Moreover, silent tape is a great option for businesses that prioritize customer satisfaction. When packaging items for shipment, especially fragile or delicate items, using silent tape ensures a professional and polished appearance. The absence of loud noise during the packaging process also avoids potential disturbance or annoyance to customers, both during the packaging phase and when they receive their packages. Additionally, silent packaging tape is often designed with high-quality adhesive properties. This means that it provides a secure and durable seal, keeping packages intact during transit. This reduces the likelihood of damaged goods and the associated costs of re-shipping or replacing items. Lastly, silent tape is often made from eco-friendly materials. This is advantageous for businesses aiming to reduce their environmental impact. By choosing silent packaging tape made from recyclable or biodegradable materials, companies can align their packaging practices with their sustainability goals. In conclusion, the benefits of using silent packaging tape include noise reduction, improved employee satisfaction and productivity, enhanced customer experience, secure sealing, and eco-friendliness. By opting for silent tape, businesses can create a more efficient, pleasant, and environmentally conscious packaging process.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q: What are the tapes for packing tape?

- Size, core, stationery, glue, wet water, leather tape, double sided tape series

- Q: Does packaging tape have any specific certifications or standards?

- Packaging tape possesses specific certifications and standards. Various organizations and standards establish guidelines for packaging materials, including packaging tape. One of the most prevalent certifications for packaging tape is the ISO certification from the International Organization for Standardization. ISO establishes quality management system standards, and packaging tape can acquire certification under ISO 9001:2015 to ensure that it meets specific quality criteria. Apart from ISO certification, packaging tape can also conform to industry-specific standards like those set by ASTM International or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards guarantee that the tape satisfies particular requirements concerning strength, adhesion, and durability. Furthermore, certain packaging tapes may possess certifications associated with their environmental impact. For instance, specific tapes may be certified as recyclable, biodegradable, or made from sustainable materials. Organizations like the FSC or the SFI grant these certifications to promote responsible forestry practices. It is crucial to note that not all packaging tapes will possess certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it indicates that the product satisfies particular quality, performance, or environmental criteria.

- Q: Is packaging tape safe to use on painted surfaces?

- Yes, packaging tape is generally safe to use on painted surfaces. However, it is recommended to test a small, inconspicuous area first to ensure that the tape does not damage or peel off the paint.

Send your message to us

Vinyl Packaging Tape for Auto and Normal Painting Masking Reviews

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords