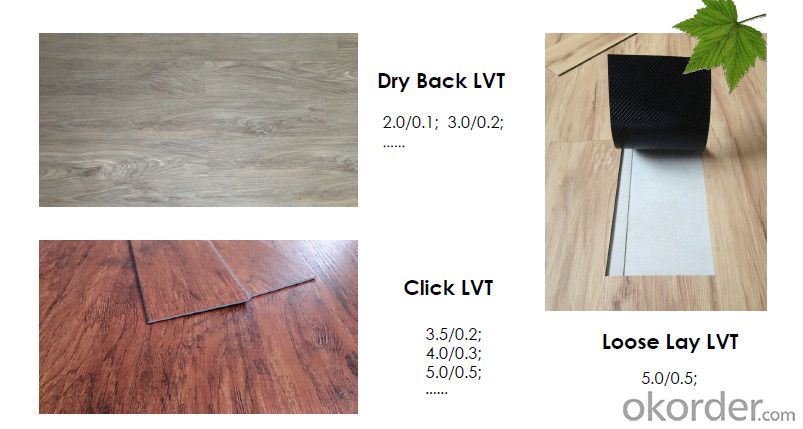

Vinyl Flooring 3.5mm Thickness With Various Designs MDM 004

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packing Detail: In carton/pallet as requested.

Delivery Time: 20 days after received 30% prepayment.

Application:

Vinyl flooring is widely used in office,super market,hospital,house,

bathroom,Kitchen and other commercial places.

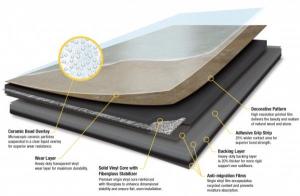

It is made of wear layer,pvc material and printed layer,which is a new type floor decoration material in the world.

Because environmental,cheap,easy to install,colorful and light than ceramic tile,

the vinyl foor is very popular.

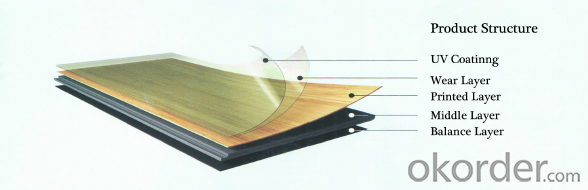

Product Structure:

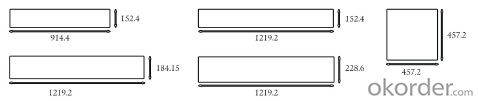

Size:

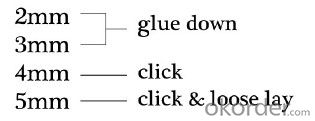

Thickness:

Specification:

Production:

- Q: That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- First, the purchase is the key to how to choose some of the moisture resistance of the ceramic tile, is the key to continue to enjoy the dry life in winter, there are six criteria for everyone to choose. The first: low water absorption rate of this tile usually have good moisture resistance, when buying, we can crack is tile surface observation, other glaze layer thick ceramic tile will also increase the moisture resistance of ceramic tile to a certain extent. Therefore, the user in the selection of ceramic tiles to watch the special table when the water content, water content less, good moisture-proof tiles, of course, the price is also high

- Q: Board PVC plastic floor plastic toxic

- Board PVC plastic floor is a green plastic decoration materials, no poison.

- Q: What is the home improvement PVC plastic floor

- Printing film: imported printing layer and the printing layer produced by the domestic production of the color and fidelity is very good, and the general production of small printing layer is prone to fade. Consumers in the purchase of the best looking for a high degree of integrity of the business to buy, so as not to fade the color of the plastic floor, the impact of beauty. Wear resistant layer: due to the different manufacturers, the quality of the wear-resistant layer is also a big difference, the poor quality of the wear-resistant layer in addition to easy cracking is also easy to shrink, resulting in the edge of the floor. Also recommend consumers to find a high degree of integrity of the business to buy PVC floor.

- Q: 2mm thick PVC plastic floor is generally one square meter

- The answer is not unique.PVC floor coil and blocks, and the wear layer thickness is not the same. Weight is not necessarily the same.I specialize in Bonie PVC flooring.Generally 1KG per square meter

- Q: Badminton plastic floor? Want to be a sports venue, which plastic sports floor brand is better

- Badminton plastic floor with shock absorption sports protection to enhance the friction of the ball to provide better sports experience is very worthy of choice

- Q: What glue paste on plastic floor

- Plastic flooring is a broad term. There are a variety of views on the network, it should be said is not very accurate, plastic floor is a very popular in the world today, a new type of light ground decorative materials, also known as "light material".Adhesive resin (epoxy resin) generally refers to the epoxy resin as the main body of the adhesive, epoxy resin should also include epoxy resin curing agent, otherwise the glue will not solidify

- Q: PVC plastic flooring should be how to pave the road, want to shop this floor, but do not know PVC plastic floor price per square meter of stone? Tell me what the trouble!

- For different horizon: 1, cement: Horizon must clean wet (if it is to be painted after the paint is dry), all cracks and holes with suitable fillers (such as gypsum). 2, wood floor: to ensure that the original floor clean, clean, no glaze, no wax, no oil, and firmly stick to the ground, the filling of all cracks and holes with the appropriate (such as gypsum). 3, PVC floor: remove all dirty oil or wax floors, must not be laid on the soft plastic or rubber floor, the floor will be removed or covered with a layer of three plywood, and the filling material is suitable for all cracks and holes (such as gypsum).

- Q: 3dMAX plastic flooring how to paste like tiles

- Overall, if you want to quickly compare the overall reflection of the tile is not a high reflection of the fuzzy reflection, the floor is not a reflection of low brick joints, slightly fuzzy ~ ~ more than testing

- Q: How to clean plastic floor

- 3, wash with detergent again, dry the surface of the plastic floor of the sewage, and then wash the same water again, dry the water after the completion of the. 4, clean plastic floor should pay attention to the prohibition of the use of acid cleaning agent and powdered detergent, otherwise it will damage and corrosion of the stone surface, try to avoid using rough ground to avoid the stone surface friction material, leaving a permanent scratch. 5, plastic floor cleaning standards are clean and transparent, no pollution, no trace.

- Q: Our hostel is covered with plastic foam, so it's hot now

- Although the bubble floor is not good, but it is very practical, but also just started with the taste of the big points, a few days there is no

Send your message to us

Vinyl Flooring 3.5mm Thickness With Various Designs MDM 004

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords