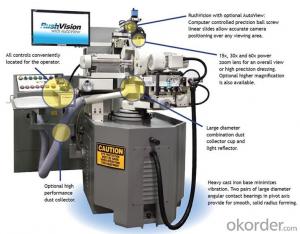

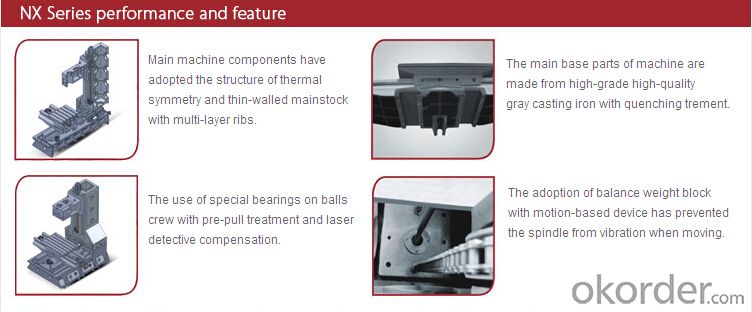

Vertical CNC Milling Machine Modle:NX36,low price economical

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The strength and rigidity of millling machine is improved 50%. The rigidity and stability of cutting feed are enhanced so as to improve the machine processing accuracy and using life.

SPEC

| Model No. | NX30 | NX36 | NX-5 | |

| Capacity | X axis travel/mm | 500 | 600 | 700 |

| Y axis travel/mm | 300 | 360 | 450 | |

| Z axis travel/mm | 450 | 450 | 550 | |

| Spindle nose to table surface/mm | 90-540 | 150-600 | 150-700 | |

| Spindle nose to column surface/mm | 350 | 380 | 520 | |

| Feedrate | X,Y,Z rapid traverse/M/min | 15/15/15 | 15/15/15 | 15/15/15 |

| Max cutting feedrate(M/min) | 10 | 10 | 10 | |

| Spindle | Spindle speed/rpm | 60-8000 | 60-8000 | 60-8000 |

| Spindle taper/spindle shank | 7:24 Taper BT40 | 7:24 Taper BT40 | 7:24 Taper No.40 | |

| Max spindle inner diameter/mm | Φ60 | Φ60 | Φ70 | |

| Spindle motor(30 mins,mitsubishi)/kw | 3 | 5.5 | 7.5 | |

| Accuracy | Positioning accuracy/mm | ±0.005 | ±0.01 | ±0.01 |

| Repeatability positioning accuracy/mm | ±0.003 | ±0.005 | ±0.005 | |

| Machine size | Machine height/mm | 1800 | 2260 | 2330 |

| Space requirement(L*W) | 2200*2000 | 2500*1870 | 2560*2300 | |

| Net machine weight/kg | 2000 | 3000 | 4500 | |

| Power requirement/KVA | 10 | 10 | 15 | |

| Drive motor/kw | 1./1.0/1.0 | 1./1.0/1.0 | 1.5/1.5/1.5 | |

| Control system | Snytec or HNC | Snytec or HNC | Snytec or HNC | |

| Worktable | Table size/(L*W) | 600*300 | 700*360 | 700*450 |

| Max load on the table/kg | 300 | 300 | 400 | |

| T-slot size/mm | 18*3*105 | 18*3*110 | 18*3*110 |

| Main machine configuration | 1. cnc milling machine control system: Syntec EZ4 controller From Taiwan. HNC servo motor; |

| 2. frequency-changing spindle,6000rpm, 7/24 Taper No.40; | |

| 3. fully enclosed splash guard; | |

| 4. pneumatic cylinder for unclamp tools; | |

| 5. screw rod chip removal system; | |

| 6. metal sheet cover for guide rail; | |

| 7. work and alert lamps | |

| 8. cooling system and water tank | |

| 9. heat exchanger | |

| 10. auto lubrication system; | |

| 11. 380/220v 50Hz transformer. | |

| 12.High speed bearing. | |

| 13.cnc milling machine with 4th NC indexing head FK15145 |

- Q: One flew over the cuckoos nest pg 41-77Characterize Pete Bancini with regards to the theme of Machinery. Please give examplesThanks!

- Bancini worked on the rail road for a long time he sees things in the world like a machine.

- Q: in a donut shop? names? thanks so much

- check okorder /

- Q: What are the listed companies of construction machinery in China? What are the shares of A?

- You download a Sina access, there are engineering machinery section, all stocks can be found. Very convenient。 Please take it if you have any help. Thank you

- Q: ...machinery?

- Your question is somewhat redundant. If someone has been fired for this than I would assume they can be fired for it and I'm basing this answer based on the fact that they were fired. For the most part, if someone was fired it seems logical that they can be fired. Are you asking if they should be fired?

- Q: Where can I purchase 1/32 scale working RC Machinery and tractors. I see all of these videos on YouTube (will put links below) with these amazingly detailed working rc tractors and stuff. Where do these people get them from. I am noticing everyone of these videos is made in Germany. I am in the US. Please help is there a website for them.

- Rc Tractors

- Q: What kinds of construction machinery are used in the Three Gorges Project?

- Tower crane, dump truck, combined flatbed trailer set, concrete mixing tower, tower belt machine, double wheel milling machine, high pressure rotary jet pump.

- Q: Does the US export military things to China such as aircrafts and artillery machinery?

- No. After the Tiananmen Square massacre of 1989 the US (and the EU) imposed an arms embargo on China, which is still in effect.

- Q: i need this answer its urgent

- you can't do that job by using any air craft. please use a space craft.

- Q: Why do many medications caution the consumer not to operate heavy machinery?

- Cos of opium

- Q: What printing process is it that allows you to print a design on a t-shirt and then you can wash the t-shirt and the design will stay on? Silkscreen printing?

- direct okorder

Send your message to us

Vertical CNC Milling Machine Modle:NX36,low price economical

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords