Various Types Rectangular Tube Pultrusion Machine of New Design

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 22 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Various Types Rectangular Tube Pultrusion Machine of New Design

Product Description:

This production line can be used to produce different size and type FRP products with different moulds. It is totally auotomatic, so it just needs one person to operate the machine,to save the labour force at the greatest extent.

Product Features:

1. Traction gantry make ordered according to requested length

2. We used the latest technology: pump is multi-group pump source (to ensure stability in forward speed). Hydraulic parts are made of stacked clip (easy maintenance), and the tension and clamping force can make stepless adjustment .

3. It has single and double manually operated gantry and double gantry automatic reciprocating running function. Automatic intermittent time can be automatically set, and the actual production tension can be feedback by sensor.

Product Parameter:

Name | Various Types Rectangular Tube Pultrusion Machine of New Design |

Brand | CMAX |

Weight | 5T |

Dimension(L*W*H) | 6.8m*1.5m*3.2m |

Power | 15KW |

Voltage | 220V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001 |

Appilication | Profile |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Selectable |

Warranty | 1 Year |

Time of Delivery | 30-45 days |

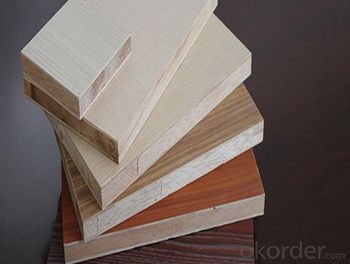

Product Pictures:

FAQ:

Q: Can your factory customize the machine for clients ?

A: Yes, we can.

Q: How about after-sales service ?

A: 1 year free warranty, Lifetime technical service support.

Q: How can I install the production line and get a commissioning ?

A: We may send our engineer for installation and commissioning, but relevant cost will be paid by you.

Q:Have you some videos where we can see the line producing?

A: Yes, we can provide some videos.

- Q: What machine does the pattern design of this mass produced plastic product use?

- Hello, let me answer the question for you: you can open your mobile phone, Baidu, and then enter your current location, and then enter the address you want to query. The Baidu maps will automatically navigate the nearest route for you.

- Q: PPO plastic mold commonly used steel processing?

- Application range6 polyphenylene ether is high strength engineering plastics development 60s of this century, it has high mechanical strength and creep resistance; excellent electrical properties, high temperature to 120 DEG C, and in a wide temperature range, stable size, mechanical properties and electrical properties change little; absorption of water vapor is very small. Cooking. Widely used in electronic, electrical components, medical equipment, cameras and office equipment, and so onCommon problem7 injection molding process characteristics and process parameters of modified polyphenylene oxidePolyphenylene oxide (also known as: polyphenylene oxide) [PPO] has good chemical stability, low creep, aging resistance, and it is not easy to burn. Because of its good water resistance, polyphenylene oxide is widely used as an engineering plastic.The major disadvantages of polyphenylene oxide are: poor flowability of melt, difficulty in forming process, tendency of cross linking, expensive price, easy stress cracking and unstable impact strength.

- Q: What are the standard tolerances for engineering plastic products machined (e.g. lathes, milling machines)?

- No, look at the drawings, requirements, no note tolerances, drawings should be marked, and if there is no mark, then there is a problem with drawings. Drawing requires that all elements be annotated.

- Q: How should be the material after refining to smooth feeding, shredders or other equipment?.

- After refining can also screw? Open mill, mixer, used as rubber industry pro. The material on the twin screw extruder must be powder and pellets.

- Q: What is the function of adding filler in the processing of plastic products?

- See what kind of filler you add, different products, different filler properties are not the same

- Q: What kind of equipment does the plastic product factory need?

- The current plastic, if the raw materials and semi-finished products are relatively low profits, it is recommended to do directly in the above color printing, the added value of high. Like universal printer, you can achieve this effect. In some plastic shell, plastic, plastic stationery and other top brands.

- Q: ABS plastic processing flow

- ABS resin is a three element copolymer developed on the basis of modification of polystyrene resin. A stands for acrylonitrile, B for butadiene, and S for styrene. ABS resin has three components, the comprehensive performance of A can improve the oil resistance, chemical corrosion resistance, which has a certain surface hardness; B ABS showed a rubbery toughness, improve impact toughness; S ABS plastics showed good fluidity, which has a good performance of thermoplastic plastic molding processing. ABS plastic is mainly used in the manufacture of instruments, instruments, household appliances, telephones, TV sets and so on. ABS plastic is used to make metal luster, and ABS is used instead of metal. Our factory produces various types of refrigerator liner and all kinds of plastic products, ABS injection products accounted for more than 88% of the total refrigerator plastic products

- Q: where there are advanced environment-friendly recycled plastic processing equipment? Thank you

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: How do we calculate the cost?

- So many people bought equipment and started, most of the friends have just started, mainly chemical fiber bags (PP woven bags) granulation, plastic film granulation, plastic bottles, broken materials, and so on.2, followed by the main problem is the use of equipment:1). Performance of the equipment are not familiar with the problems of using too much, such as temperature control is not good (low price devices do not have automatic temperature control system, through experience), products can not achieve the desired requirements, the color is not good, drawing off a serious, low yield, often blocking filter, cutting unevenness, severe adhesion.2) raw materials sorting is not clear, cleaning is not in place, impurities, broken bar serious, bad color. The same raw materials, the same approach, the product is not as good as others, the price is far from.3), procurement of raw materials, usually all recycled plastic, when you formed a batch production, to ensure the supply of raw materials can not be too much, impurities in raw materials procurement, and even pit you encounter people, buy a home is water, stone bag.4) sales problems: I don't know who sells the products. I don't know what the price is, or even say you have such and such problems.Moreover, the beginning of production, it is impossible to form mass production, small amount of bad sales, because customers need to be generally enough to a car to load, 2T-3T is not good, and more afraid of production, fear of backlog.

- Q: Where are home plastic products, plastic products for daily use, plastic products processing, plastic products, mold

- You are looking for people to give you the processing mold, is it, then you go to the hook online to find ah, above doing this factory a lot

Send your message to us

Various Types Rectangular Tube Pultrusion Machine of New Design

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 22 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords