Valve with Competitive Price with 60year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

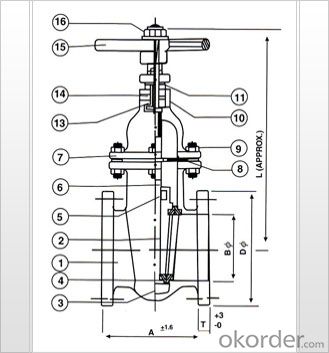

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What does the J41Y-100I valve type mean?

- J41Y-100I flange type chrome molybdenum steel valve forgingJ represents the cut-off valve, 4 (flange) on behalf of his connections, 1 (straight) on behalf of his structure, Y (seal) on behalf of his seat sealing surface or liner material code, 100 is the nominal pressure value, I (chrome molybdenum steel) is the code of the body material

- Q: How to identify the good or bad of the valve, without pressure test and instrument?

- First, the appearance, two according to the standard to see flange thickness, outer circle, wall thickness and other dimensions are standard, 3 see details.

- Q: How to suppress the valve?

- How does the valve press the pressure test pump?. How much pressure do you need to use the pressure pump for the corresponding specifications?. There is a specially suppressed machine pressure test pump. How much pressure do you need to use the pressure pump for the corresponding specifications?

- Q: Why is copper used in cryogenic valves?

- The rigidity of copper is better, and the friction parts are not easy to produce adhesion. The influence of temperature on copper is smaller than that of steel. Especially in the valve stem, there is also the important gear part, copper!

- Q: Who knows which kind of water valve is good?

- Classification of domestic valves:pipeline valveBathroom valves, kitchen valves, etc faucetsPipeline valve is generally sealed with rubber valve is better, rubber sealed valve sealing performance is very good and durable;Bathroom valves, kitchen valves and other faucets will use copper into the Dian valve, copper valve is not rusty, durable. ,Hope to help you.

- Q: How to check the quality of the valve?

- First of all, to check the appearance of the valve is smooth and smooth. Cast valves without sand holes and obvious flaws. Forged valves check nominal pressure or pound level.Second, check the material of the valve, that is, the material composition, this is very important, the material does not meet the standard on the device will be a big problem.Finally, check that the switch is sensitive and the signs are clear. Test pressure is the last step.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: What's the name of the valve?

- Specific models only go to the original manufacturers to find, and want to use other valve replacement is not impossible, want to provide detailed parameters. Let's go to the valve manufacturer!

- Q: Which valve can play a good regulatory role?

- A wide range of valves, the function is different, although like conventional butterfly valve, ball valve can play a regulatory role, but their role is not linear, so if you need to adjust the precision of the valve, it is best to select the control valve.

- Q: How do you understand the valve Z41X-16?

- This is a standard set, the landlord himself to check the JB/T308 standard, Baidu library, some, and is free to download:JB/T 308-2004 valve type method of preparation clear EditionZ = gate valve4 = connection: flange1 = structural form: open rod single gateX = sealing surface material: Rubber16 = nominal pressure: 1.6MPa16 there is no letter behind it indicates that the body is made of cast iron

- Q: Valve pressure grade division

- Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves, chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

Send your message to us

Valve with Competitive Price with 60year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords