Steam Globe Valve Size: 1/2 with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

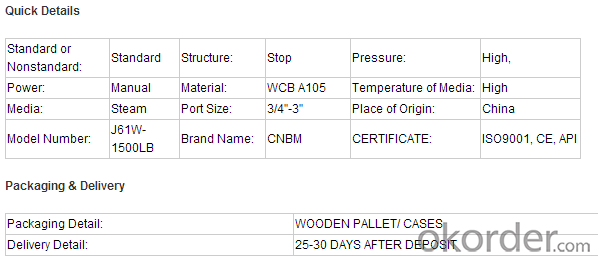

Specifications

ANSI Globe Valve

1) valves range from 3/4" - 2" .

2) export to overseas

3) More than 20 years manufacture experience

Globe Valve industrial suppliers

1) Size: 1/2"-3"

2) Pressure: 800lbs/1500lb

3) Applicable temperature range: 180-425.C

4) Material: WCB A105

5) Applicable medium: steam, oil, gas

- Q: What are the definitions of internal, external and leakage valves?

- Upstairs to say there is a problem. The leakage within the valve that is the reason of erosion wear medium makes the valve is not closed tightly, even if the valve screw (stem) screwed in place, because there is still a gap between the spool and the valve body, the medium can flow past. Outside leakage generally refers to the valve and connecting flange or threaded connection between the seal and guide...

- Q: Measure the temperature with a thermocouple, and then how to make the valve open when the temperature reaches a certain value. When the temperature is lowered, will the valve be closed?Or tell my brother what is the knowledge, I can see it myself. Good. How much extra?!

- A relay or PID controller can achieve this operation, only need to set out, the valve can use electromagnetic valve, which belongs to a rapid opening and closing valves, only need to control the electric power to the valve can automatically open or closed, but the temperature change is large, if you want to keep the temperature constant. The best selection of regulating valve, constant temperature control valve will be before or after the valve, the main electrical control knowledge, do not know what I said is clear, remember the points, thank you!

- Q: What is a lift rod valve?

- Lever valve stem nut in the valve plate, it with the disc (hand wheel) to open the turn, its stem pull the valve head and higher than the valve disk, also known as the bar valve. It is different from the dark rod valve, dark rod valve stem nut in the valve body, when the disc rotates, the stem will not rise.

- Q: Chinese valve and a valve which is better?

- Look what valve you use, ah, these two can be ah!

- Q: The valve is rusty and can not be opened. What shall I do?

- For removing loose rust agent Penpen, later replaced

- Q: What does valve DN50/80 mean?

- Hello landlord DN50 valve refers to the valve diameter of 50mm DN80 is 80mm if the valve is opening and closing function, so the valve diameter should be and pipeline with the diameter or smaller number, large waste, butterfly valve to be stuck in the flange, the influence of flow.If the role of the valve is adjusted, and that caliber will be different from the pipe diameter, this is not to reduce the cost of the problem, is a result of calculation, and this calculation results with flow, pressure drop and valve resistance curve.For example, control valve, usually smaller than the pipe diameter, such as pressure reducing valve, will be smaller than the pipe diameter to two, such as 57mm pipe with DN50.

- Q: What should be checked before using the valve?

- The valve must be visually checked before installation1, valve opening and closing position should meet the following requirementsThe valve, the cut-off valve, throttle valve, regulating valve, butterfly valve, foot valve, the valve is in full closed positionPlug valves and ball valves should be in full open position? diaphragm valve should be in the closed position, and can not be too tight to prevent damage to the diaphragmCheck valves shall be closed and secured2, the valve shall not be damaged, missing parts, corrosion, nameplate shedding and other phenomena, and the valve body shall not be dirty3, both ends of the valve should be protected. Handle or handwheel should be flexible and light, and must not be stuck4, valve body casting, the surface should be smooth, no cracks, blisters, lock, pores, burrs and other defects; outside valve forging, the surface should be free of cracks, interlayer, double skin, scar defect

- Q: What are the types of valves?

- 1.2.1 sort by pressurex09 (1) vacuum valve operating pressure below standard atmospheric pressure valvex09 (2) low pressure valve nominal pressure PN is less than or equal to 1.6 MPa valve.x09 (3) medium pressure valve nominal pressure PN, 2.5, 4, 6.4 MPa valvex09 (4) high pressure valve nominal pressure PN 10.0~80.0 MPa valvex09 (5) high pressure valve nominal pressure PN = 100 MPa valve.1.2.2 classification by dielectric temperaturex09 (1) high temperature valve for medium working temperature T > 450 degrees of the valvex09 (2) medium temperature valve for medium temperature 120 degrees valvex09 (3) at room temperature valve for medium temperature -40 = t = 120 DEG C of the valve.x09 (4) low temperature valve for medium temperature -100 = t = -40 C of the valve.x09 (5) ultra low temperature valve for medium working temperature T < -100 DEG C valve

- Q: I would like to ask commonly used water valve what kind of? What are the characteristics?

- The valve is usually composed of two parts: the actuating mechanism and the valve bodyAccording to the power used by the executing agency, the valve can be divided into four kinds: manual, pneumatic, electric and hydraulic. According to its function and characteristics, it can be divided into on-off valve, regulating valve, electromagnetic valve, electronic type, intelligent type, etc.According to the type of the body: through single seat, through two seater, angular, diaphragm, three links, eccentric rotation, butterfly, sleeve type, spherical and other 10 kinds of; according to the valve body material: cast iron, cast steel, forged steel, carbon steel, stainless steel, copper, plastic valves.

- Q: How can the material be checked by valve approach? What experiments do you need?

- May refer to the valve pressure test principle and the pressure test matters needing attention.(1) in general, the valve shall not be subject to strength test, but the body and bonnet shall be subjected to strength tests after the repair of the valve body and bonnet or corrosion damage. For the relief valve, the constant pressure and seat return pressure and other tests shall be in accordance with the specifications and the relevant regulations.(2) the installation of the valve should be done for strength and tightness test. Low pressure valve sampling 20%, if not qualified should be 100% of the inspection; medium and high pressure valve should be 100% of the inspection.(3) the installation position of the valve shall be in the direction of easy inspection during the test.(4) welding connection valve, not with blind plate pressure test can be used when the cone seal or O ring seal pressure test.(5) when hydraulic test, the valve air will be excluded as much as possible.(6) the pressure should be increased gradually during the test, and the pressure will not be sudden and sudden.(7) strength test and sealed test duration is generally 2~3min, important and special valves should last 5min. Small caliber valve test time can be a little shorter, large caliber valve test time can be longer. During the test, the test time can be extended if in doubt. Strength test, does not allow the body and bonnet sweating or leakage. Sealing test, the general rotor valve only once, the safety valve, high pressure valve and other raw valve to be carried out two times. When testing for the low pressure, large diameter valve is not important and there are provisions to allow leakage of the valve, allowing a small amount of leakage; the common valve, power station valve, marine valves and other valve requirements vary on leakage requirements according to relevant regulations.

Send your message to us

Steam Globe Valve Size: 1/2 with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords