V350 Series High Performance Vector Control ac Frequency Converter 50hz 60hz

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Single phase 220V,380V;

Vector control,

cost efficiency

small

Product Description

V350 series low-power closed-loop vector inverter

To satisfy the needs of equipment like machine tool, printing, textile and chemical fiber, V350 series inverter is designed on the basis of new hardware platform. Characterized by the excellent performance, compact structure, perfect protection function and various peripheral interface, V350 series inverter can be used for the secondary development in accordance with process

requirement in all kinds of field.

Basic function

Open/closed-loop vector control

Torque control

Motor parameter’s self-identification

Wobbling

Excessive current, voltage inhibition and low voltage inhibition

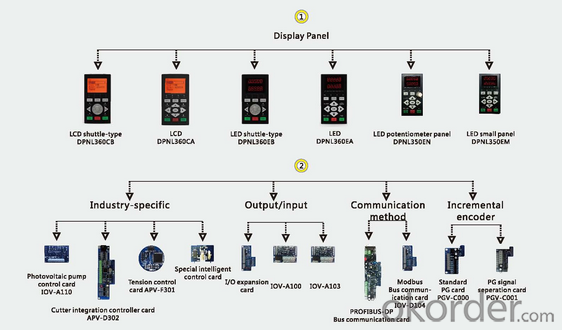

MODBUS/Profibus-DP communication

Synchronous communication linkage

Three-phase balance protection

Short circuit of protection

Function highlights

Setting simplification

One-click setting of common parameters

Virtual I/O port

Timer

Counter

Specifications

Input&output | Rated voltage/freq. | Three phase(4T****)380V 50/60Hz | Single phase(2S****) 220V~50/60 Hz |

Output voltage | 0~380V | 0~220V | |

Output freq | Low freq running mode:0.0~300.0 Hz. high freq running mode: 0.0~1000.0 Hz | ||

Digital input | V350-4T0030/2S0022 model below: standard five-way (DI), V350-4T0040 above:standard six-way(DI) | ||

Digital output | V350-4T0030/2S0022 model below: standard one-way (DO),V350-4T0040 model above: standard two-way DO | ||

Impulse input | 0.0~100.0K Hz impulse input, connect optional NPC OC output | ||

Impulse output | 0.0~100.0kHz impulse output NPC OC output available, support choosing PWM output method as the expansion analog output terminal | ||

Analog input | Standard configuration:0~10V voltage input(AI1), 0~20mA current input (AI2); standard expansion I/O card: -10V~10V voltage input | ||

Analog output | V350-4T0030/2S0022 model below: one-way 0~10V analog output signal ( optional 0~20 mA current output mode) V350-4T0040 above: two-way 0~10V analog output signal ( optional 0~20 mA current output mode)

| ||

Contactor output | Standard one pair of frequent open/closed AC 250V/2A contactor, allowing for expanding one to six pairs of contactors | ||

control characteristics | Control method | Close-loop vector control | Open-loop vector control | V/F control | |

Starting torque | 220% at zero speed | 200% at zero speed | 180% at zero speed | ||

Adjustment range | 1:1000 | 1:200 | 1:100 | ||

Speed stabilization accuracy | ±0.02% | ±0.2% | ±0.5% | ||

Torque control accuracy | ±5% | ±5% | — | ||

Torque response time | <5ms | <25ms | — | ||

Freq resolution ratio | Low freq running mode: 0.01 Hz: high freq running mode: 0.10 Hz | ||||

Freq accuracy | Low freq running:digital set—0.01Hz analog setting-the highest freq 0.1% High freq running: digital set-0.1 Hz, analog setting-the highest freq 0.1% | ||||

Loading capacity | 110% for long term; 150% for 60s, 180% for 2.5s; | ||||

Carrier freq | Three-phased voltage vector synthesis mode: 1.5~10.0 k Hz, two-phased voltage vector synthesis mode : 1.5~12.5 k Hz | ||||

Acceleration/deceleration time | 0.01~600.00Sec./ 0.01~600.0 Min | ||||

Magnetic flux brake | Increase the motor magnetic flux(30%~120% optional) to realize the fast brake for acceleration and deceleration | ||||

DC brake/ clasp brake | DC brake/clasp brake starting freq:0.0~upper rate limit, brake/clasp injection current 0.0~100.0% | ||||

Starting freq | 0.0~50.0Hz | ||||

Typical function | Multi-segment running | 16 freq/speed running, independent setting of direction, time acceleration and deceleration of each part, 7 PID setting |

Built-in PID | Built-in PID controller which can be used as external equipment | |

Sleep | Simple sleep and wake up function | |

MODBUS communication | Optional standard MODBUS communication protocol, flexible parameter reflexive function | |

Dynamic braking | Dynamic voltage: 650~760V, braking rate: 50~100% | |

General function | Failure restore, power to restart, motor parameter dynamic.static self detection, starting delay, current inhibit over voltage low voltage inhibit,V/F self defining curve |

Function highlights | Virtual I/O port | Eight-way virtual output/input port with no need to combine any external wiring to realize the complex application |

Synchronous communication linkage | Synchronous driving between different motors with no limit to communication linkage, freely choose linkage balance according to current, torque and power | |

Loading dynamic balance | Realize several motors’ dynamic balance and torque motor characteristics | |

Powerful starting torque | Support setting powerful starting torque in a certain time to deal with the load of large inertia and static friction | |

Priority setting | Freely choose prior sequence according to the freq, rotating speed setting channel, adjust to all kinds of field | |

Portfolio setting | More than one hundred of freq, rotating speed and torque | |

Timer | Three built-in timers: five kinds of clocks, five kinds of starting trigger mode,,several gated signal and working mode, seven output signal | |

Counter | Two built-in counters : the choose of clocks, four kinds of starting trigger mode, seven output signal | |

Macro parameter | Application macro: convenient to set several paris of fixed parameters and simplify the parameter set of general field | |

System macro: convenient to switch the working mode,such as the switchover between the high and low freq., and automatically define parts of parameter | ||

Parameter debugging | Any unsaved parameters in the spot can be saved, abandoned and restored into the original value | |

Parameter display | Automatically shield the parameters of unused module or selectively display the parameter altered, saved and changed |

Environment

Installation environment

Vertical installation with no direct sunshine, dust, corrosive and combustible gas, smoke and steam

Altitude

0~1000 meter . 10% reduced output current for each 1000 meter rise

Temperature

Working environment: -10°C~ +45°C storage environment: -20°C~ +60°C

Moisture

95% below (no frosting)

Vibration

<20m/s

FAQ

Q 1. what's the payment term?

A. We accept T/T, L/C, WEST UNION

Q 2. What's the delivery time ?

A. Normal model,0-3days,

For big order(more than 10,0000 usd),it takes about 7-15days. Customer make will be longer but with not over 15 days.

Q 3. What is the standard of package?

A. Export standard package or special package according to customer requirement

- Q: Laptop power adapter current is not the same alternative?

- so the output voltage, the same output polarity, the output current of the adapter can be used in smaller power notebook, and small power adapter can not be used to give Powerful notebooks,

- Q: The relationship between the power supply of the notebook and the battery

- 1, when the notebook battery is fully charged, and connected to the power adapter, usually by the adapter directly to the host power supply, this time the battery is idle, the adapter power supply without battery conversion.

- Q: What is the single axis of the inverter and multi-axis applications

- Inverter is the application of frequency conversion technology and microelectronics technology, by changing the motor power supply frequency and amplitude of the way to control the AC motor power transmission components.

- Q: What is the characteristic of the variable pole speed method?

- Third, cascade speed control method Cascade speed regulation refers to the winding motor in the rotor loop into the adjustable additional potential to change the motor slip, to speed control purposes. Most of the slip power is absorbed by the additional potential in series, and the additional device is used to return the absorbed slip power to the grid or to convert the energy. According to the slip power absorption and utilization, cascade speed can be divided into motor cascade speed, mechanical cascade speed control and thyristor cascade speed form, the use of thyristor cascade speed, which features: The process of the slip loss back to the grid or production machinery, the higher efficiency; device capacity and speed range is proportional to the investment province, for speed range in the rated speed of 70% -90% of the production machinery; Device failure can be switched to full speed operation, to avoid shutdown; thyristor cascade speed power factor is low, the greater the impact of harmonics. This method is suitable for use in wind turbines, water pumps and rolling mills, mine hoists, extruders. Fourth, winding motor rotor series resistance speed control method Winding asynchronous motor rotor series into the additional resistance, so that the motor slip increase, the motor running at a lower speed. The greater the resistance of the series, the lower the motor speed. This method is simple and easy to control, but the slip power is consumed in the form of heat. Is a level of speed, mechanical characteristics of soft.

- Q: The notebook power adapter flashes

- The problem is very simple Well, used to know all the notebook Kazakhstan, the adapter has a light above, if it is lit that is the problem of the notebook, the other side of the notebook above also have a power indicator, the notebook above prompted the red, but not Rushed, that is, the problem of the notebook, the computer problem, you directly on the factory is finished, if the insurance, and casually find a place to repair a Kazakhstan, 50-80 yuan if the adapter is bad, buy a generic You can, but also more than 50 points, the last time I bought a bad 58 yuan, ASUS GM, to help people in the end, to give you a shop to buy the adapter, you ask the owner of Kazakhstan to get,

- Q: Can the HP laptop's power adapter be universal?

- Power supply low-voltage plug to the same, the voltage to the same, the current is greater than or equal to can be used

- Q: Is the laptop power adapter AC and DC?

- Most laptop power adapters can be used for 100 ~ 240V AC (50 / 60Hz). Basically, most of the notebook computers are external power supply, with a power cord and the host connection, which can reduce the size and weight of the host, only a very small number of models built in the host power.

- Q: Three-phase motor, quadrupole asynchronous motor to 15rpm, the inverter output how many volt voltage? The 4 V

- The voltage is basically the same, the inverter changes the frequency of the power supply, not the voltage.

- Q: Short-term short-circuit converter DC link positive and negative will damage the inverter?

- This short circuit may not necessarily line, the inverter fan has three, one is no speed line, two are pulse, three are switching signal (this is very little, I only encountered several),

- Q: 30 kW 6 pole frequency motor torque is how much

- To know what is the use of ah, the inverter motor is the same with the ordinary motor, but to prevent the operation of a low speed plus a fan

Send your message to us

V350 Series High Performance Vector Control ac Frequency Converter 50hz 60hz

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords