Used in EAF as Charge Coke for Steel Mills with S 0.3%max

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Calcined anthracite can be called carbon additive, carbon raiser, recarburizer, injection coke, charging coke, gas calcined anthracite.

Carbon Additive/Calcined Anthracite Coal may substitute massively refinery coke or graphite. Meanwhile its cost is much less than the refinery coke and graphite. Carbon Additive is mainly used in electric steel ovens, water filtering, rust removal in shipbuilding and production of carbon material.

It has good characteristics with low ash, low resistivity, low sulphur, high carbon and high density. It is the best material for high quality carbon products. It is used as carbon additive in steel industry or fuel.

Features:

Best quality Taixi anthracite as raw materials through high temperature calcined at 800-1200 ℃ by the DC electric calciner with results in eliminating the moisture and volatile matter from Anthracite efficiently, improving the density and the electric conductivity and strengthening the mechanical strength and anti-oxidation, It has good characteristics with low ash, low resistivity, low carbon and high density. It is the best material for high quality carbon products, it is used as carbon additive in steel industry or fuel.

Specifications:

F.C.% | 95MIN | 94MIN | 93MIN | 92MIN | 90MIN | 85MIN | 84MIN |

ASH % | 4MAX | 5MAX | 6 MAX | 6.5MAX | 8.5MAX | 12MAX | 13MAX |

V.M.% | 1 MAX | 1MAX | 1.0MAX | 1.5MAX | 1.5MAX | 3 MAX | 3 MAX |

SULFUR % | 0.3MAX | 0.3MAX | 0.3MAX | 0.35MAX | 0.35MAX | 0.5MAX | 0.5MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX | 0.5MAX | 1MAX | 1MAX |

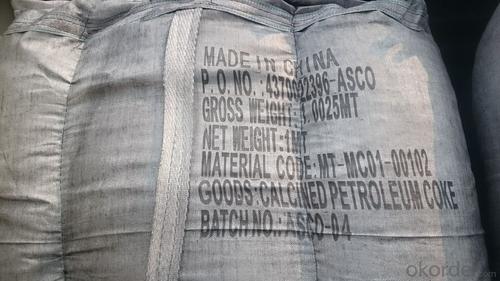

Pictures

FAQ:

Packing:

(1). Waterproof jumbo bags: 800kgs~1100kgs/ bag according to different grain sizes;

(2). Waterproof PP woven bags / Paper bags: 5kg / 7.5kg / 12.5kg / 20kg / 25kg / 30kg / 50kg small bags;

(3). Small bags into jumbo bags: waterproof PP woven bags / paper bags in 800kg ~1100kg jumbo bags.

Payment terms

20% down payment and 80% against copy of B/L.

Workable LC at sight,

- Q: Appearance, hardness, electrical conductivity, use of carbon 60

- C60 is a molecule composed of 60 carbon atoms in the molecule, it is like football, so also known as footballene (C60. This material is composed of C60 molecules, rather than by the atoms.) C60 is simply made of carbon atoms with stable molecules, it has 60 vertices and 32 sides. The 12 is Pentagon and 20 hexagon. Its molecular weight is about 720.

- Q: How does carbon contribute to global warming?

- Carbon contributes to global warming through the greenhouse effect. When carbon dioxide (CO2) and other greenhouse gases are released into the atmosphere, they trap heat from the sun and prevent it from escaping back into space. This leads to an increase in the Earth's surface temperature, causing global warming. The primary source of carbon emissions is the burning of fossil fuels such as coal, oil, and natural gas for energy production, transportation, and industrial processes. These activities release large amounts of CO2 into the atmosphere, which accumulates over time and enhances the greenhouse effect. Additionally, deforestation and land-use changes also contribute to rising carbon levels. Trees and plants absorb CO2 as part of photosynthesis, acting as a natural carbon sink. However, when forests are cleared, this stored carbon is released back into the atmosphere. Moreover, the loss of trees reduces the overall capacity to absorb CO2, exacerbating the problem. The consequences of increased carbon emissions are far-reaching. Rising temperatures result in the melting of polar ice caps and glaciers, leading to sea-level rise and threatening coastal communities. Furthermore, carbon-driven global warming disrupts weather patterns, causing extreme weather events such as hurricanes, droughts, and heatwaves. To mitigate the impact of carbon on global warming, efforts must be made to reduce carbon emissions. This can be achieved through transitioning to renewable energy sources like solar and wind, improving energy efficiency, promoting sustainable practices in agriculture and forestry, and implementing policies that encourage carbon capture and storage. Addressing carbon emissions is crucial in combating global warming and its associated consequences. By understanding the role of carbon in the greenhouse effect, we can work towards a sustainable future that minimizes the harmful effects of climate change.

- Q: How is carbon involved in the metabolism of carbohydrates, proteins, and fats?

- Carbon is a fundamental element involved in the metabolism of carbohydrates, proteins, and fats. In all three macronutrients, carbon atoms play a crucial role in the formation of their molecular structures. In carbohydrates, carbon is present in the form of glucose, which is the primary source of energy for the body. Through a process called glycolysis, glucose is broken down into smaller molecules, generating ATP (adenosine triphosphate) for cellular energy. The carbon atoms in glucose are rearranged and converted into intermediate compounds that are further used in other metabolic pathways. Proteins, on the other hand, are complex molecules composed of amino acids, each containing a carbon atom. During protein metabolism, carbon atoms participate in various reactions, such as deamination and transamination, which allow for the synthesis of new proteins or the breakdown of existing ones. Carbon atoms also contribute to the formation of peptide bonds that link amino acids together, forming the backbone of proteins. In the metabolism of fats or lipids, carbon is predominantly found in the fatty acid chains. These carbon chains provide a high-energy fuel source, as they can be broken down through a process called beta-oxidation. Carbon atoms from fatty acids are sequentially cleaved, producing acetyl-CoA, which enters the citric acid cycle (also known as the Krebs cycle) to generate ATP. Additionally, carbon atoms from fatty acids can be used for the synthesis of other molecules, such as cholesterol and hormones. Overall, carbon is an essential component in the metabolism of carbohydrates, proteins, and fats. Its involvement in these metabolic processes allows for the production of energy, the synthesis and breakdown of essential molecules, and the regulation of various physiological functions.

- Q: I bought a grill myself and went to barbecue with my friends the day after tomorrow, but I can't ignite the carbon. What should I do?

- Start with the newspaper, then take some candles, the candles melt, and the carbon!I'm 12, and I'll be all right!It's really simple!Or where do you buy carbon, buy one called "carbon steams" what?!Put the carbon in the carbon and light it. Ha!

- Q: How does carbon affect the quality of soil?

- Carbon plays a crucial role in determining the quality of soil. When organic matter, such as dead plants and animals, decomposes, it releases carbon into the soil. This process is known as carbon sequestration, and it is essential for maintaining soil fertility and health. The presence of carbon in soil promotes the growth of beneficial microorganisms, such as bacteria and fungi, which contribute to the breakdown of organic matter and the recycling of nutrients. These microorganisms help to create a rich and fertile soil environment, ensuring that essential nutrients are available for plants to absorb. Additionally, carbon in soil improves its structure and water-holding capacity. It acts as a sponge, allowing the soil to retain moisture, which is crucial for plant growth and survival. Carbon also helps to prevent soil erosion by binding particles together, reducing the risk of nutrient loss and water runoff. Furthermore, carbon enhances the soil's ability to store and release nutrients. It acts as a reservoir, holding onto essential elements like nitrogen, phosphorus, and potassium, and gradually releasing them to plants over time. This nutrient cycling is vital for sustaining healthy plant growth and productivity. Unfortunately, modern agricultural practices, such as excessive tilling, overuse of synthetic fertilizers, and deforestation, have led to a significant decline in soil carbon levels. This loss of carbon has detrimental effects on soil quality, leading to decreased fertility, increased erosion, and reduced water-holding capacity. To mitigate these negative impacts, it is crucial to adopt sustainable agricultural practices that focus on carbon sequestration and soil conservation. These practices include reducing tillage, incorporating cover crops, practicing crop rotation, and applying organic fertilizers. By increasing carbon levels in soil, we can improve its quality, promote plant growth, and ensure the long-term sustainability of our agricultural systems.

- Q: How does carbon affect the preservation of historical artifacts?

- Carbon can have both positive and negative effects on the preservation of historical artifacts. On one hand, carbon-based materials such as paper, wood, and textiles are susceptible to degradation over time. These artifacts can be easily affected by environmental factors such as temperature, humidity, and exposure to pollutants, leading to their decay. Carbon-based materials can also be attractive to pests like insects and rodents, further accelerating their deterioration. On the other hand, carbon-based materials like charcoal and carbonates can play a crucial role in the preservation of artifacts. Charcoal, for example, can be used to date artifacts through carbon dating, providing valuable insights into their age and historical significance. Carbonates, such as calcium carbonate found in limestone, can act as protective coatings, forming a barrier against environmental factors and preventing further decay. Moreover, carbon-based conservation treatments, such as consolidation with adhesives or impregnation with polymers, can help stabilize and strengthen fragile artifacts. These treatments can increase the artifact's resistance to environmental factors and provide structural support, extending its lifespan for future generations. It is important to note that while carbon-based materials can impact the preservation of historical artifacts, other factors like light exposure, handling, and storage conditions also play significant roles. Therefore, a comprehensive preservation strategy should consider all these factors to ensure the longevity and conservation of these valuable historical artifacts.

- Q: How does carbon affect the melting of polar ice caps?

- The connection between carbon and climate change has a direct impact on the melting of polar ice caps. When humans release carbon dioxide, a greenhouse gas primarily emitted through the burning of fossil fuels, it acts as a sort of blanket, trapping heat within the Earth's atmosphere. This trapped heat then leads to a rise in global temperatures, ultimately causing the polar ice caps to melt at an accelerated pace. As carbon dioxide is emitted into the atmosphere, it prevents the Earth's heat from escaping into space, much like a blanket would. Consequently, the overall temperature of the planet increases, resulting in the melting of glaciers and ice sheets in the polar regions. The more carbon dioxide is released, the more heat is trapped, leading to a further rise in global temperatures and a faster rate of ice melting. The consequences of the melting polar ice caps are significant. As the ice continues to melt, it contributes to the rise of sea levels, which poses a threat to coastal communities and ecosystems worldwide. Furthermore, the loss of polar ice diminishes the Earth's ability to reflect sunlight, as ice has a high albedo, or reflectivity. This means that as more ice melts and is replaced by darker ocean water or land, more sunlight is absorbed, further warming the planet and creating a positive feedback loop. Taking steps to reduce carbon emissions and address climate change is crucial in order to mitigate the melting of polar ice caps. Transitioning to renewable energy sources, improving energy efficiency, and implementing sustainable practices are some of the ways in which we can minimize carbon emissions and slow down the rate of ice melting. By taking action on carbon emissions, we can play a role in preserving the polar ice caps and lessening the devastating consequences of climate change.

- Q: What type of carbon copy sheet can be printed on? How many copies?

- Printed in carbon free carbon paper, usuallyUpper: whiteMedium: RedNext: yellowMainly depends on how much you want to print. Generally 100 pages, such as:One copy of the two couplet is 50 copies.One copy of the triad is 33 copies.One copy of the quadruple is 25 copies.This is a five of the 20.

- Q: What are some natural sources of atmospheric carbon emissions?

- Some natural sources of atmospheric carbon emissions include volcanic activities, forest fires, and decay of organic matter in soil and oceans.

- Q: What is the significance of the determination of total organic carbon in purified water?

- Purified water represents the total amount of organic matter in water by carbon content. It is an important indicator of water quality. The detection of total organic carbon in water is an important item for the detection of pharmaceutical water. Inspection item 2005 edition test item [1] character: This product is colorless and tasteless clear liquid. Check: pH, take this product 10ml, plus methyl red indicator liquid 2 drops, may not show red; another take 10ml, add bromine, thymol blue, indicating liquid 5 drops, may not show blue. Chloride, sulfate and calcium salt were taken in three test tubes, each with 50ml.

Send your message to us

Used in EAF as Charge Coke for Steel Mills with S 0.3%max

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches