Underground Epoxy Coated Composite Steel Pipe for Mining Steel-Plastic Pipeline Systems

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Epoxy Coated Composite Steel Pipe for Mining

Press grade: Applied for pipe system not bigger than 10MPa

Size: DN50MM-DN1600MM

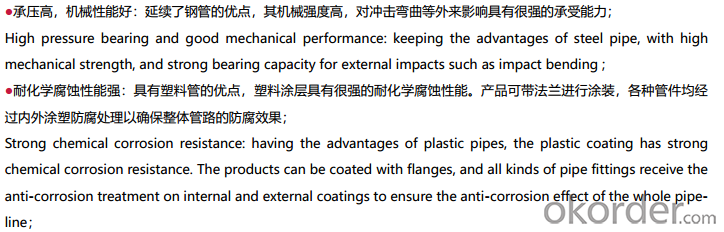

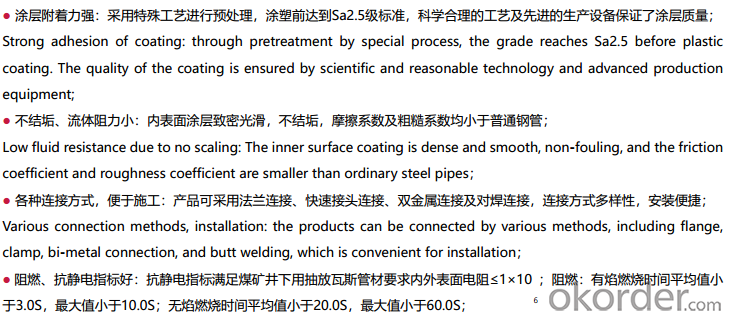

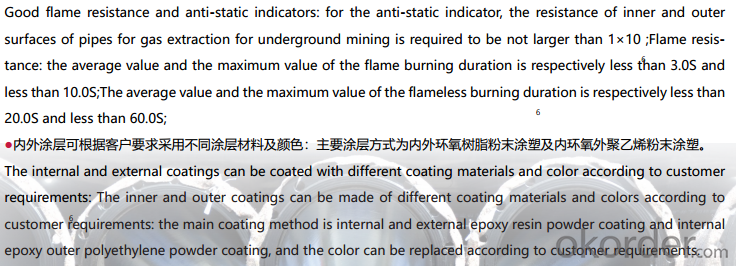

Features:

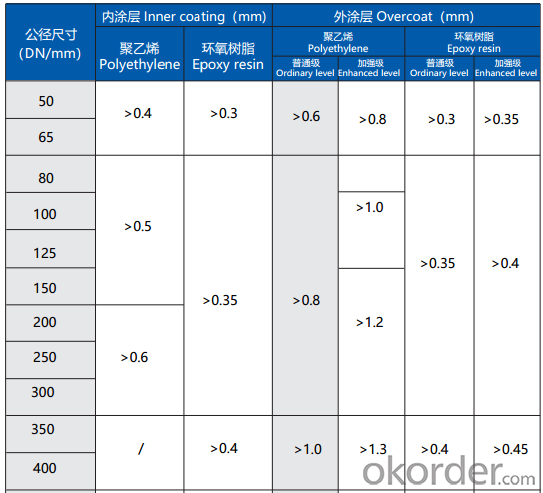

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: What are the common applications of steel pipes in the oil and gas industry?

- Steel pipes are commonly used in the oil and gas industry for various applications such as drilling, production, transportation, and distribution of oil and gas. They are utilized for casing and tubing in oil wells, conveying fluids in pipelines, and supporting infrastructure for refineries and processing plants. Additionally, steel pipes are crucial for offshore drilling operations and are employed in the construction of platforms and subsea pipelines.

- Q: Can steel pipes be used for underground electrical conduits?

- Yes, steel pipes can be used for underground electrical conduits.

- Q: What is an electric welded pipe (EFW)? Seek help!

- According to the operation requirements of the electric welding machine, connect the lead wire and set up the proper welding parameter of the electric welding machine, which can be operated by manual or automatic two input methods.After checking, start the electric welding machine and enter the welding process. When the welding time is reached, the machine will automatically enter the cooling state.When the pipe completely removed after cooling, electric fusion welding machine.Cutting the pipe with the cutting tool of plastic pipe or fine toothed saw with cutting guide device, and making its end face perpendicular to the axis of pipe. Remove the edges of the edges with a knife, scrape the weld area in the pipe or spigot end and clean the weld area.Should use the special fixture as far as possible to secure the components to be connected, and the roundness of the pipe shall not exceed 1.5% of the outer diameter of the pipe, or it should be corrected on the corresponding fixture.

- Q: What are the different types of coatings used for external protection of steel pipes?

- There are several types of coatings commonly used for the external protection of steel pipes, including fusion bonded epoxy (FBE) coatings, three-layer polyethylene (3LPE) coatings, three-layer polypropylene (3LPP) coatings, and coal tar enamel (CTE) coatings. Each of these coatings provide different levels of corrosion resistance and durability, depending on the specific requirements of the project or application.

- Q: Are there specifications for scaffold steel pipe with 48mm * 3.2mm?

- Scaffold tubes are our name for materials used to build scaffolding, because most scaffolding uses tubular bamboo or steel tubing. Bamboo and other bamboo is for a long time in the use of the scaffolding tube, but due to lack of safety and durability, now only in rural and urban area construction is lagging behind some of the home building small building has been used. The modernization construction, the most commonly used type of scaffolding pipe is steel pipe, the scaffolding should not only meet the demand of workers, but also to meet the characteristics of scaffolding firm and durable, so tough hard steel is the best choice. The selected steel pipe generally requires smooth surface, no cracks, no bending, no rust, and meet the relevant national standards.

- Q: What are the factors affecting the pressure rating of steel pipes?

- The factors affecting the pressure rating of steel pipes include the thickness and strength of the pipe material, the diameter and length of the pipe, the temperature of the fluid being transported, the type of fluid, and the presence of any corrosive substances or external loads.

- Q: What is the difference between hot-finished and cold-finished steel pipes?

- Hot-finished and cold-finished steel pipes are distinguished by their manufacturing processes, resulting in different characteristics and uses. Hot-finished steel pipes are manufactured by heating a solid steel billet to a high temperature and then piercing it to create a hollow tube. This process is known as hot rolling. The hot rolling process ensures that the steel is malleable and can be easily shaped into the desired form. Hot-finished steel pipes have a rough surface and more rounded edges. They are typically larger in diameter and have thicker walls. These pipes are commonly used in applications that require high strength and resistance to pressure, such as in the oil and gas industry, structural projects, and heavy machinery. In contrast, cold-finished steel pipes are made through a process called cold drawing. This involves pulling the hot-finished steel pipe through a die at room temperature to reduce its diameter and achieve the desired shape. The cold drawing process provides a more precise and smoother finish to the steel pipes. Cold-finished steel pipes have a smoother surface and sharper edges compared to hot-finished pipes. They are generally smaller in diameter and have thinner walls. Cold-finished steel pipes are commonly used in applications that require precise dimensions, such as automotive parts, construction components, and machinery manufacturing. Overall, the main difference between hot-finished and cold-finished steel pipes lies in their manufacturing processes, resulting in variations in surface finish, dimensions, and applications. Hot-finished pipes are suitable for high-strength and pressure-resistant applications, while cold-finished pipes are ideal for precise dimensions and smooth surface requirements.

- Q: What are the different international standards for steel pipes?

- The industry recognizes and utilizes multiple international standards for steel pipes. Some noteworthy standards are as follows: 1. ASTM A53: This standard encompasses black and galvanized steel pipes, both seamless and welded. It finds common application in low-pressure scenarios involving water, gas, and steam. 2. ASTM A106: This standard covers seamless carbon steel pipes designed for high-temperature usage. It sees widespread use in refineries, power plants, and petrochemical industries where elevated pressure and temperature conditions prevail. 3. ASTM A312: This standard pertains to austenitic stainless steel pipes that are seamless, welded, and heavily cold worked. It is frequently employed in industries such as chemical processing, food processing, and pharmaceuticals, where high temperatures and corrosive environments are encountered. 4. API 5L: This standard outlines the requirements for manufacturing seamless and welded steel pipes for use in pipeline transportation systems within the petroleum and natural gas industries. It specifies two product specification levels (PSL1 and PSL2). 5. EN 10216: This European standard addresses seamless steel pipes utilized for pressure purposes. It finds application in various industries, including power generation, chemical, and oil and gas. 6. JIS G3454: This Japanese standard focuses on carbon steel pipes used for pressure service, commonly employed in the transportation of water, gas, and oil. 7. DIN 2448: This German standard provides specifications for seamless steel pipes used for general purposes. It is extensively utilized across various industrial applications. These examples represent only a fraction of the numerous international standards governing steel pipes. Each standard delineates distinct requirements concerning manufacturing, dimensions, mechanical properties, and testing to ensure the pipes' quality and performance in specific applications. Manufacturers, suppliers, and users must comprehend and adhere to the relevant standards to guarantee the safe and reliable utilization of steel pipes.

- Q: What is the difference between steel pipes and polyethylene pipes?

- Steel pipes are made of a strong and durable material, steel, which makes them suitable for high-pressure and high-temperature applications. They are also resistant to corrosion, making them ideal for transporting liquids and gases. On the other hand, polyethylene pipes are made of a flexible plastic material, which makes them easier to install and handle. They are lightweight, resistant to chemicals, and have a low risk of corrosion. However, they may not be suitable for very high-pressure or high-temperature applications.

Send your message to us

Underground Epoxy Coated Composite Steel Pipe for Mining Steel-Plastic Pipeline Systems

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords