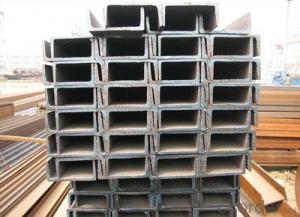

U Channel Steel the Length Thickness According to the Customer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

- Q: What are the different surface finishes available for steel channels?

- Steel channels offer a variety of surface finishes, each with its own advantages and uses. Some commonly used finishes include: 1. Hot-Dip Galvanized: This process involves immersing the steel channel in molten zinc, creating a protective coating. It is perfect for outdoor applications or environments with high humidity or chemical exposure due to its excellent corrosion resistance. 2. Powder Coating: By applying dry powder and heating it, a durable and protective layer is formed on the steel channel's surface. This finish comes in various colors and provides outstanding resistance to chipping, scratching, and fading. It is often used for decorative purposes or when aesthetics matter. 3. Electroplating: Through electrolysis, a layer of metal like chrome or nickel is deposited on the steel channel's surface. This finish enhances appearance, offers corrosion resistance, and can even improve hardness or wear resistance, depending on the plated metal. 4. Painted: Steel channels can be painted with different coatings like epoxy, acrylic, or enamel. Painting provides both a visually appealing look and protection against corrosion. The type of paint can be chosen based on factors like durability, weather resistance, and color options. 5. Stainless Steel: Steel channels can be made from stainless steel, which naturally resists corrosion. They are commonly used in applications where hygiene, high temperatures, or exposure to aggressive chemicals are concerns. The choice of surface finish for steel channels depends on specific requirements such as corrosion resistance, durability, aesthetics, and environmental factors. Seeking advice from a steel supplier or surface finishing expert can help determine the most suitable finish for a particular project.

- Q: Do steel channels have any specific load distribution characteristics?

- Yes, steel channels have specific load distribution characteristics. They are commonly used in construction and engineering applications to distribute loads evenly across their cross-sectional area. The shape of steel channels allows for efficient transfer of loads, providing strength and stability to structures. Additionally, the design of steel channels can be optimized for specific load distribution requirements, making them versatile in various structural applications.

- Q: Can steel channels be used for conveyors?

- Yes, steel channels can be used for conveyors. They are commonly used in conveyor systems for their strength, durability, and versatility in various industrial applications.

- Q: How do steel channels contribute to the sustainability of a building?

- Steel channels contribute to the sustainability of a building in several ways. Firstly, they are highly durable and have a long lifespan, reducing the need for frequent replacements or repairs. This minimizes the overall environmental impact associated with the production and disposal of building materials. Additionally, steel channels can be easily recycled at the end of their life cycle, reducing waste and conserving natural resources. Furthermore, steel channels are lightweight, allowing for more efficient transportation and installation, which reduces energy consumption during construction. Lastly, steel channels provide structural strength and support, allowing for the design of more sustainable and space-efficient buildings.

- Q: Can steel channels be used for signage installations?

- Yes, steel channels can be used for signage installations. They provide strength, durability, and stability, making them suitable for securely mounting and supporting signage.

- Q: What are the disadvantages of using steel channels?

- Some disadvantages of using steel channels include their relatively high cost compared to other materials, their susceptibility to corrosion if not properly protected or maintained, and their limited versatility in terms of shapes and sizes available. Additionally, steel channels may require specialized equipment and expertise for installation and may not be suitable for certain applications where weight reduction is important.

- Q: The base is a fixed support, and the load is evenly distributed at three points, respectively, at 50010001500 points and three points, the base is rigidly fixed, and the top is connected and fixed

- The stability of channel steel can not be checked, and the flexural strength of channel steel is checked only. The following bending moment diagram can be obtained by calculation8 =Mmax/ (gamma Wx) +N/A=1875N - m/ (1.05*39.7cm - <[f]=205N/mm - +0/12.74=45N/mm fand), to meet the requirements.The Mmax in the upper form is derived from the diagram, and is computed by itself as 1875N, m=1875000N, mm;Gamma cross-section plastic development coefficient, 1.05;Wx No. 10 steel section modulus, look-up table, Wx=39.7cm =39.700mm fand fand;N steel axial force, 0;A channel section area, look-up table, A=12.74cm L.

- Q: What are the applications of steel channels in construction?

- Steel channels have a wide range of applications in construction due to their strength, durability, and versatility. Here are some of the key applications of steel channels in construction: 1. Structural Support: Steel channels are commonly used to provide structural support in buildings, bridges, and other infrastructure projects. They can be used as beams or columns to carry loads and distribute weight effectively. 2. Framing: Steel channels are often used in framing applications, especially for walls, ceilings, and roofs. They provide a strong and reliable framework, ensuring the stability and integrity of the structure. 3. Staircases and Handrails: Steel channels are ideal for constructing staircases and handrails due to their strength and rigidity. They provide a safe and durable solution, especially in high-traffic areas. 4. Reinforcement: Steel channels can be used to reinforce concrete structures, such as foundations, walls, and slabs. By adding steel channels, the strength and load-bearing capacity of the concrete are significantly increased. 5. Mezzanine Floors: Steel channels are commonly used to create mezzanine floors, which provide additional space in buildings without the need for expanding the footprint. Steel channels offer a lightweight yet sturdy solution for supporting the floor structure. 6. Industrial Racks and Shelves: Steel channels are widely used in the construction of industrial racks and shelves. Their load-bearing capacity and durability make them suitable for storing heavy equipment, materials, and products. 7. Infrastructure Projects: Steel channels find extensive applications in large-scale infrastructure projects, including bridges, tunnels, and railways. Their high strength-to-weight ratio makes them ideal for withstanding heavy loads and resisting environmental factors. 8. Architectural Design: Steel channels are often used in architectural design to create unique and aesthetically pleasing structures. They can be shaped and welded into various configurations, allowing architects to bring their creative visions to life. Overall, steel channels play a crucial role in the construction industry, offering a reliable, durable, and versatile solution for various applications. Their strength, load-bearing capacity, and flexibility make them indispensable in modern construction projects.

- Q: What are the limitations of using steel channels?

- Using steel channels in various applications comes with several limitations. To begin with, cost is a major drawback. Steel channels tend to be relatively expensive compared to materials like wood or certain types of plastics. This higher cost can make them less viable for projects or industries with strict budget constraints. In addition, steel channels are typically heavy and bulky, which can pose challenges during transportation and installation. The weight of steel often requires additional labor and equipment, leading to increased project costs. This aspect may also restrict their use in applications where weight is a crucial factor. Another limitation is corrosion. Steel is susceptible to rusting and corrosion over time, especially in environments with high moisture or exposure to specific chemicals. This corrosion can weaken the structural integrity of the steel channel, necessitating regular maintenance or protective coatings to prevent or slow down the process. Moreover, steel channels have limited design flexibility. Unlike materials like wood or plastic, steel channels are not easily shaped or molded into intricate designs. This lack of design flexibility can restrict their use in architectural or decorative applications where aesthetics play a significant role. Lastly, steel channels can conduct heat and electricity, which may not be desirable in certain applications. For instance, in electrical systems or sensitive electronic equipment, steel channels may require insulation or replacement with non-conductive materials to prevent electrical hazards or interference. In conclusion, although steel channels are strong and durable, they do have limitations regarding cost, weight, corrosion, design flexibility, and electrical conductivity. These limitations should be carefully considered when determining the suitability of steel channels for a specific project or application.

- Q: Can steel channels be used for curtain wall framing?

- Yes, steel channels can be used for curtain wall framing. They provide structural support and can withstand the required loads and pressures associated with curtain wall systems.

Send your message to us

U Channel Steel the Length Thickness According to the Customer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords