Monolithic Refractories for Cement Industry - Tundish Magnesite Dry Ramming Mix

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

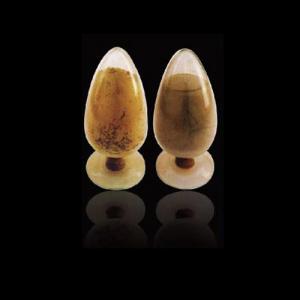

tundish magnesite dry ramming mix

1. Convenient installation

2. Anti-corrosion

3 ISO Approved

tundish magnesite dry ramming mix

convenient installation, anti-corrosion, long service life

excellent disintegration performance, easy separation and purifying function (the main components are MgO, ).

Type | HD-JZ80 | HD-JZ80 | HD-JZ60 | HD-JZ50 | |

MgO(%) | ≥80 | ≥70 | ≥60 | ≥50 | |

CS(MPa) | 200°C×3h | ≥3 | ≥3 | ≥2.5 | ≥2 |

1550°C×3h | ≥3 | ≥3 | ≥3 | ≥3 | |

Bulk Density(g/cm3) | 200°C×3h | 2.2~2.5 | 2.2~2.4 | 2.0~2.3 | 1.9~2.2 |

high temperature performance and high-density, strong anti-permeability ability and easy to rapid sintering, very thin sintered layer,good thermal shock stability, strong slag-resistance, long service life and so on.

Mainly used in producing common magnesite brick, magnesite aluminum brick, magnesite chrome brick, gunning mix, hot patching mix for converter and EAF ect .

- Q: The research direction of unshaped refractory for cement kiln

- In fact, the classification of refractory refractories is very much, and specific, you are to use in which part of the cement kiln, different parts of the refractory used are not the same

Send your message to us

Monolithic Refractories for Cement Industry - Tundish Magnesite Dry Ramming Mix

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords