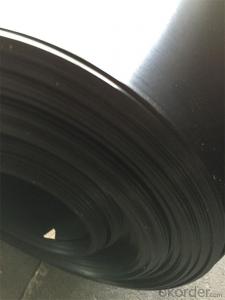

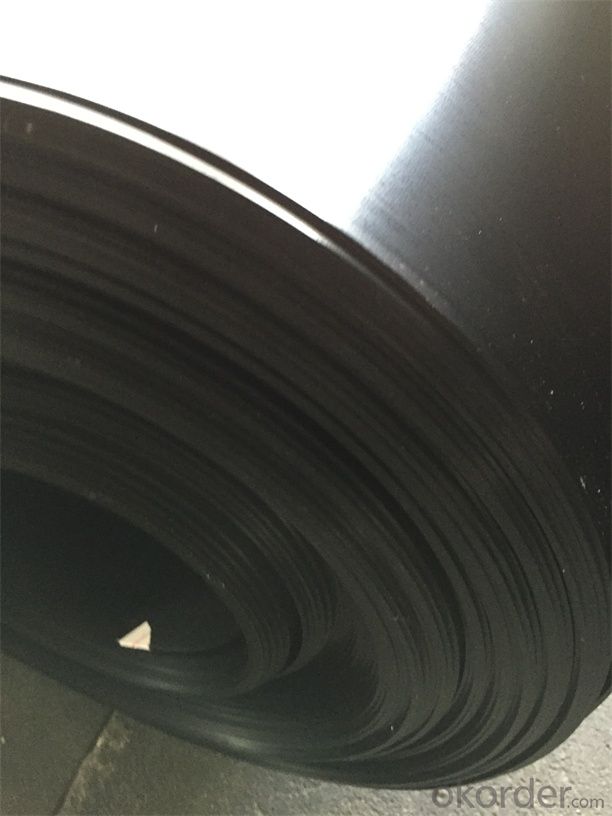

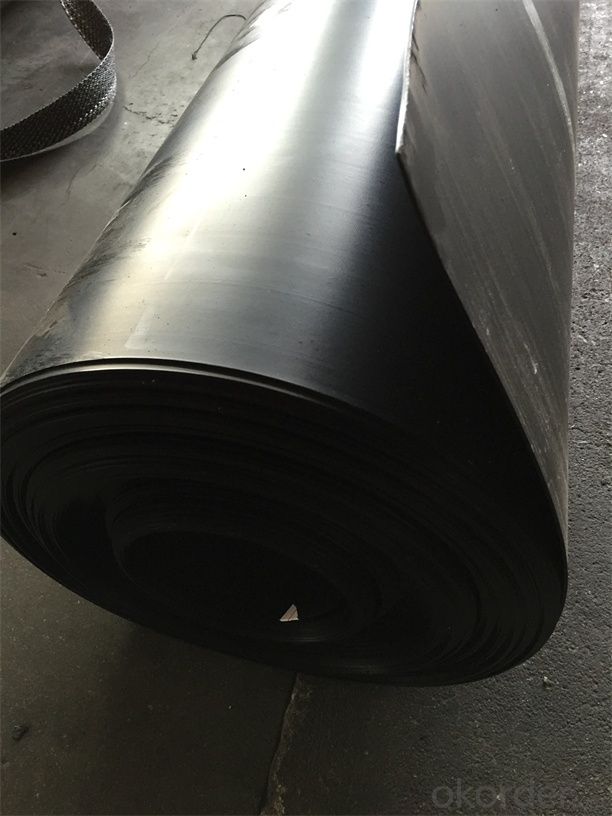

TPO Geomembrane HDPE Pond Liners HDPE Geomembrane Smooth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geomembrane

1.Gas Defence fish pool liner vinyl pool liners

2.1m-8m width

3.0.2mm-3.0mm thickness

Geomembrane specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE geomenbrane Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Geomembrane Applications

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

HDPE geomembrane technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

Gemembrane Show:

- Q: welding specifications of composite geo-membrane.

- ①lap joint: lap joint width shold be 15cm; ② hot welding: Suitable for thicker geomembrane weld lap width of the substrate to 5CM. (Recommended bonding, soak the glue in water, poor seepage-proof effect.) digging the base into protective layer of mortar in the bottom of the lake(H20-30mm), slope cutting, dense and smooth composite geomembrane and vertical bulkhead, smooth pasted base surface, clear, step transfer of water pipe mouth sealed with sealing geomembrane laying welding and repair welding procedure handover quality acceptance, completion and acceptance of a high-level design: About 0.6m 2, waterproof construction total area is about 800㎡ 3,ceramsite brick built bulkhead, 4, collapse pit set by water

- Q: What are the considerations for geomembrane selection in landfill gas collection systems?

- When selecting a geomembrane for a landfill gas collection system, several factors need to be considered. These include the compatibility of the geomembrane material with the landfill gas components, its permeability, durability, and resistance to punctures and tears. The geomembrane's ability to withstand chemical exposure and UV degradation is also crucial. Additionally, factors such as installation requirements, cost-effectiveness, and regulatory compliance should be taken into account to ensure the successful operation and longevity of the landfill gas collection system.

- Q: What are the limitations of geomembranes in seismic-prone areas?

- Geomembranes, although widely used for various applications, have certain limitations in seismic-prone areas. Firstly, their susceptibility to damage during earthquakes is a significant concern. The intense ground shaking can cause the underlying soil to shift, leading to potential tears, punctures, or even complete failure of the geomembrane. Additionally, the movement of the soil can induce strain on the geomembrane, resulting in excessive deformation or stress concentrations that may compromise its integrity. Moreover, the compatibility of geomembranes with the underlying soil or rock layers can affect their performance. In seismic-prone areas, the dynamic behavior of the soil and its interaction with the geomembrane need to be carefully analyzed to ensure proper design and installation. Thus, understanding these limitations and implementing suitable reinforcement measures is crucial to ensure the effectiveness and reliability of geomembranes in such areas.

- Q: How to pave the electrothermal?film?

- Attention should be paid to several aspects when paving ceramics on electrothermal?films: first, is waterproof insulation should deal be well prepared; second, the concrete used to pave ceramics should not be too thick. The thickness should be controlled within 50mm (the thickness of concrete and ceramics, such thickness is convenient for heat transfer); third, expansion joints of ceramics must be retained(because floor heating system will lead to heat expansion and cold contraction); fourth, the temperature increases slowly which avoids expansion caused by excessive heat; fifth, the electrothermal film power should be controlled within 80W/square meter in accordance with the room size; sixth, load must be calculated before the installation of temperature controller so as to avoid the line fault of temperature?controller; seventh, phase line must be allocated reasonably in accordance with the inlet wire of the room(now the inlet wire uses three-phase four-wire system) so as to save energy, electrothermal film input lines in several rooms should be separately connected to inlet wire, and single-phase overload should be avoided. Remarks: Electrothermal membrane belongs to safety facilities, so the quality of products is in the first place(good quality of electrothermal film, high temperature resistant power line, multi-strand wires and joints should be welded, insulation treatment should be carried out after welding, and luted with glue) and construction quality is in the second place, consider, it should be no risk at all.

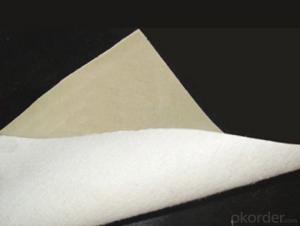

- Q: Composite membrane of geomembrane

- At the same time, has the function of isolation and reinforcement, coastal mud flat. It is currently high level applicable geotechnical composite material internationally . When combining the warp knitting. 4, namely use Warp knitted binding line. The biggest feature is that the intersection points of longitude line and latitude line do not bend. hiphotos, also has the waterproof performance of geomembrane: //a. Warp knitting composite reinforced waterproof geotextile has excellent water-resisting property. 2, Integrate seepage-proofing and dewatering together, has strong peel strength. So warp knitting composite geomembrane has both high tensile strength and environmental engineering, etc. large friction coefficient. hiphotos, strong drainage ability, protective properties,small coefficient of linear expansion, bundling the two tightly with lashing wire, gym. So the warp knitting composite geomembrane is a reinforced, high combined strength

- Q: Is PVC preservative film toxic?

- Experts told the reporters that the plasticizer allowed to add in other countries will remain stable in room temperature, but DEHA which is banned by the countries can release at room temperature from the preservative film and penetrate into the food, especially in the packaging of food with higher fat content. At present, according to the material, food preservation film is divided into polyethylene, also known as PE preservative film, polyvinyl chloride, also known as PVC preservative film, polyvinylidene chloride, also known as PVDC preservative film. Among them, PVC and PE preservative film are used most commonly. PE preservative film is mainly sold in all kinds of supermarkets, and PVC preservative filmi is mainly used as food packaging in fresh and bulk food area in the supermarket, in addition to purchase by various hotels and restaurants and other group customers. In all kinds of preservative film, PVC due to the cheap price has the largest market share, about 60% to 70%.

- Q: What are the considerations for geomembrane repairs?

- When considering geomembrane repairs, it is important to assess the extent and location of the damage, as well as the underlying causes. Factors like the size of the damaged area, the type and thickness of the geomembrane material, and the surrounding environmental conditions should be taken into account. Additionally, the repair method should be compatible with the geomembrane material and ensure long-term durability. Proper surface preparation, selection of appropriate repair materials, and following manufacturer guidelines are crucial considerations to ensure effective and lasting repairs.

- Q: Which kind of computer dull polished film is better?

- Screen can be divided into mirror screen and matte screen. Mirror screen is relatively clear but has strong light reflection, which is suitable for use in indoor dark conditions, if often go out and used in the bright environment, for example outdoor, it is enough to stick a layer of dull polished protective film. Matte screen reflect lees light, whose translucency is also inferior to mirror screen, to put it bluntly, it is not that clear. The benefit is that we can clearly see the screen no matter in hard light or outdoor environment. If in indoor weak light environment, it can be used stick nonopaque film property screen protective film definition, but it also increases the light reflection, so you can choose different films according to your using environments.

- Q: What is the role of geomembranes in landfill construction?

- The role of geomembranes in landfill construction is to act as a barrier to prevent the leakage and migration of contaminants from the waste into the surrounding environment. They are used as liners or covers to isolate the waste materials, protect groundwater resources, and minimize the potential for pollution.

- Q: Can geomembranes be used in floating covers for liquid containment?

- Yes, geomembranes can be used in floating covers for liquid containment. Geomembranes are impermeable materials that are commonly used in various applications, including floating covers for liquid containment. These covers help prevent the liquid from being exposed to the atmosphere, thus reducing evaporation and contamination risks.

Send your message to us

TPO Geomembrane HDPE Pond Liners HDPE Geomembrane Smooth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords