Top-Grade Ceramic Fiber Blanket Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

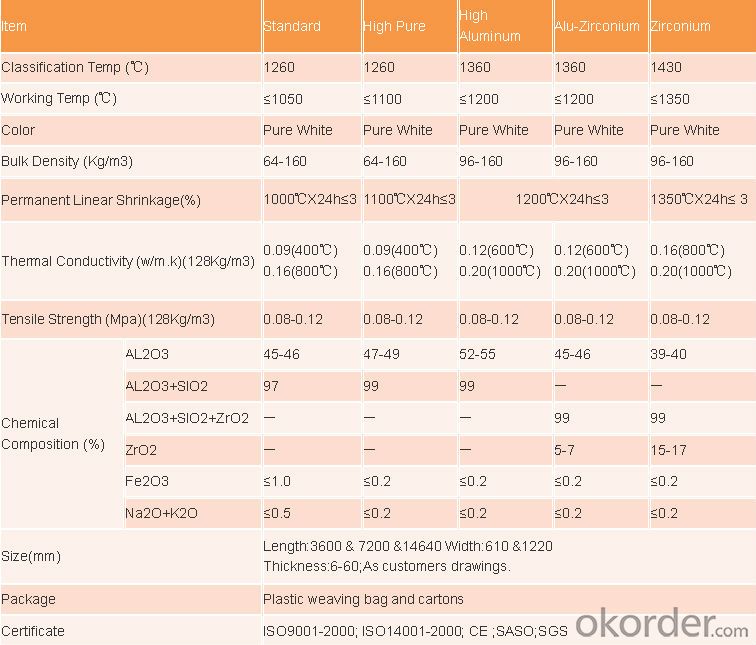

1. Type:STD, HP, HA, HZ

2. Density:64-160kg/m3

3. Service temp:1050-1350C

4. ISO9001:2000, Rohs report

5. Thermal insulation

Aluminum silicate ceramic fiber blanket is manufactured from aluminum silicate fiber bulk spinning from kaolinite, alumina silicon dioxide and zircon sand, which been series processing of needling ,cutting and rollings, including 1260°C Standard, 1260°C High pure, 1360°C High Aluminum,Alu-Zirconium 1430 C Zirconium ceramic fiber blanket.

Product information

Item | Ceramic Fiber Blanket |

Type of Blanket | Standard,High Pure, High Aluminum ,Al-Zirconium,Zirconium. |

Classification Temperature | 1260°C,1360°C,1430°C |

Applications | •The industry kiln, heating device, high temperature pipe lining •Power boiler, gas turbine and heat and nuclear power insulation •Chemical industrial high temperature equipment and heating equipment lining •Fireproof and heat insulation for high building •High-grade household appliances thermal insulation device •High temperature filtration etc |

Features | •Low thermal conductivity, low thermal capacity •Excellent thermal stability and good resistance to heat shock •Excellent tensile strength •Good anti-stripping performance •Good Sound-absorbing performance •Non-brittleness material, good flexibility •Excellent machining performance •Resistance to wind and erosion, long service life •Excellent heat insulation, fire prevention, sound absorption performance |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash. |

Delivery Time | Within 15 days after received the deposit. |

Technical data

- Q: Which company needs the new refractories?

- The power plants are mainly used in steel plant, lime kiln, coking plants, boilers, etc. I will try my best to answer what I can. There are too many glassworks. You can tell me more anout what you need. As long as there is a large kiln business, the refractories and aluminum manufacturer are needed.

- Q: What's the maximum temperature that the high-temperature resistant refractory ceramic fiber cotton can endure?

- Nichrome wire, stainless steel wire and glass fiber are reinforced. Ceramic fiber coating cloth and slag cloth, sintering ceramic fiber cloth and ceramic fiber fumigation cloth) Characteristics of the ceramic fiber cloth: high temperature resistance, low heat conductivity, thermal shock resistance, low thermal capacity; superior insulating property at high temperature, long service life; resistance to nonferrous metals like molten aluminum and zinc erosion; low and high temperature strength; innocuity with no adverse effect on the environment; Applications of ceramic fiber cloth: It can be applied to the thermal insulation of all kinds of furnaces, high-temperature pipelines and vessels; furnace doors, valves, flange seal, fire doors, fire resisting shutters and high-temperature furnace door curtains; engine and instrument insulation, clad material of fireproof cables, and high-temperature resistant and fire-proof materials; thermal insulation cloth for coverage, high-temperature expansion gap padding, and inner linings of the flue; high temperature resistant labor safety products, fireproof suits, high-temperature filtration and sound absorption, replacement of asbestos, etc.

- Q: Development trend of refractories

- Facing the survival and development of refractory industry challenges in many aspects, serious: 1, the user industry due to the progress of science and Technology (such as iron, iron and steel industry in the direct reduction furnace, to reduce casting, slag splashing etc.), reduce refractory material consumption; 2, refractory material environmental protection and ecological requirements; 3, users of the product quality and cost requirements; 4, users risk transfer, refractory material, the design requirements of the liner construction, maintenance services, and even provide construction equipment; 5, between refractory enterprises and personnel dispute price; 6, due to the industry downturn in some countries, the decline in refractory material and the lack of education, lack of young professionals; 7, resource depletion and other raw materials.

- Q: How many types of special refractories are there?

- Metal ceramics, high temperature coatings, high temperature fiber and other reinforced materials

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- Physical and chemical property indexes of high strength and high alumina refractory bricksProject indexPLG-1.0 PLG-0.8 PLG-0.5 PLG-0.4AI2O3% 56545250Fe2O3%, 2, 2, 1.5, 1.5Bulk density g/cm3 1, 0.8, 0.5, 0.4Normal temperature compressive strength MPa shall be no less than 7531.5A change of a burn line of not greater than 2%The temperature is 1400140012501250 centigradeThe coefficient of thermal conductivity, W/m.k average temperature (350 + 5) is not greater than 0.45, 0.35, 0.25, 0.20

- Q: How is the fire endurance of the fireproof paint?

- time is different according to the amount of fireproof paint used. fire resistance time :0.5 hours 1.5 hours 2.0 hours 2.5 hours thickness: 0.45mm 0.9 mm 1.4 mm 2.0 mm 2.8 mm Amount: 0.79kg / m2 1.5 kg / m2 2.3 kg / m2 3.3 kg / m2 4.6 kg / m2

- Q: What's the difference of fire-resistant material's density, specific gravity and bulk specific gravity?

- glass

- Q: Fefractory of aluminium oxide.

- It can be refined into castable refractory and refractory bricks, according to temperature rating. There are shaped refractory material and shapeless refractory material, and ceramic fiber. So it must be specific. There is a large range of refractory, which basically contains the aluminium oxide.

- Q: What are the specifications of refractory kilns ?

- Since the coefficient of thermal expansion of the basic brick is large, expansion rate is about 1-1.2% under 1000 ℃ The literature indicates that: "Under the condition that the temperature was raised to 1000 ℃ and stress in brick lining is relaxed, 300N / mm2 of compressive stress can be produced, which is equals to ten times structural strength of ordinary magnesia chrome brick, six times structural strength of magnesia chrome brick, dolomite brick and spinel brick, so any basic bricks can not afford, " the paper also pointed out that " heat expansion rate of kiln body can partially compensate for expansion rate of the inner lining of 0.2% -0.4%, which is 1/3 of thermal expansion rate of ordinary magnesia-chrome brick under 1000 ℃. However, it occurs under thermal equilibrium conditions. Thereby, the kiln should be dried slowly, allowing the temperature of the kiln body to go up slowly, thus the role of compensation can be played. " This is the key to using the basic brick. " Procedures of refractory for cement kiln "( tentative one) has clearly regulated baking and cooling of the kiln in the first section of the fifth chapters. In the heating process, in particular when the temperature is in the range of 300-1000 ℃, heating rate must be less than 60 ℃ / h. This is very clear in theory but it is difficult to implement.

- Q: What's the commonly used refractory material for ladle?

- 1. According to the refractoriness, it can be classified as follows: common refractory: 1580℃ ~ 1770℃; high grade refractory: 1770℃ ~ 2000℃; superrefractory: 2000 ℃; 2. According to the shape and demension of the product, it can be classified as follows: standard form : 230mm×113mm ×65mm of no more than four measuring scale, (demension ratio) Max: Min

Send your message to us

Top-Grade Ceramic Fiber Blanket Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords